Folding is a fundamental bookbinding technique involving the precise folding of sheets of paper to achieve smaller formats and increase the functionality of printed products. This seemingly simple operation is the basis for the production of most advertising materials, publications and specialized documents, but requires knowledge of proper techniques and industry terminology. The importance of folding in modern printing goes far beyond the mechanical folding of paper - it is a precise process that affects the aesthetics, functionality and durability of the final product. Automation of this activity through specialized machines such as folder machines offered by Akonda, allows you to achieve professional results while maintaining high production efficiency.

What is folding and why it is crucial

Folding, also known as folding or breaking, is the technical process of folding a larger sheet of paper to produce a double or multiple smaller format. The name "folding" comes from German and is commonly used in the Polish printing industry, although the official technical term remains "breaking." Both terms mean exactly the same bookbinding operation and are used interchangeably in practice.

The primary purpose of folding is to print format optimization - converting large printing sheets into practical, smaller sizes suitable for specific applications. Folding a sheet in half three times, for example, yields a 16-page fold, which is the basis of the book production and magazines. The process also provides significant economic benefits By making efficient use of the paper surface and aesthetic advantages By achieving even, precise folds.

Today's folding applications cover a wide spectrum of products - from advertising leaflets and promotional brochures, to folding maps and educational materials, to banknotes and official documents. In each of these cases, the quality of workmanship directly affects the functionality and professional appearance of the final product.

Folding line as a technical element

The folding line, also referred to as the falcu or fracture, is the place of precise bending of a sheet of paper, which after folding creates a new edge of the product. The technical characteristics of this line are fundamental to the quality of the entire process - it must be perfectly straight, even and provide a durable fold that will not break during use.

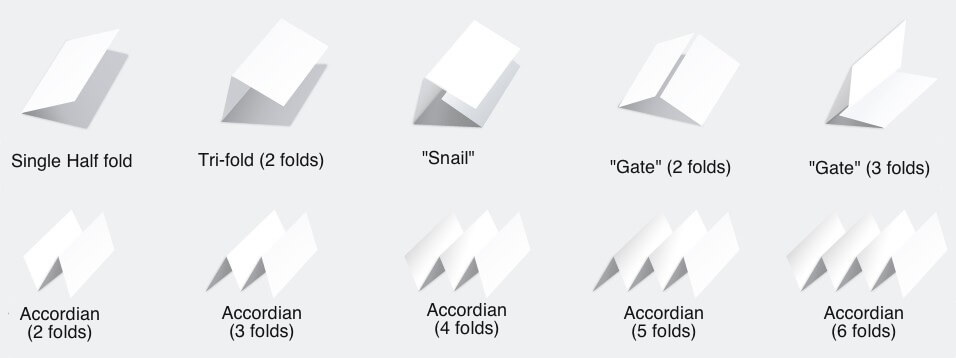

We distinguish between two basic types of folding lines. Parallel folds They are characterized by the fact that all lines run parallel to each other, which is ideal for the production of advertising leaflets and simple brochures. Cross bows are lines that intersect at right angles, used in the creation of books, catalogs and complex multi-page layouts.

Among the popular folding patterns are accordion folding forming a zigzag effect with identical wing widths, wrapping folding known as "altar" with smaller side wings, and folding including C-shaped. Each of these patterns is applicable to different types of products and requires customization of the manufacturing technique.

Technical differences between folding and creasing

Key to professional performance is understanding the difference between folding vs creasing. Folding is the right folding process suitable for thin papers of less than 150-170 gsm. Bigging Instead, it represents a preparatory process that involves making indentations in thicker paper or cardboard to facilitate subsequent bending without fiber breakage.

The choice of the right method depends primarily on the grammage of the material. Standard papers can be folded directly, while higher-weight materials require pre-creasing. This process involves bending the sheet with a blunt knife, which weakens the fiber structure and enables a clean, aesthetic fold.

The direction of the paper fibers represents critical technical factor - The folding should run along the fibers, which significantly reduces the risk of cracking and ensures a professional appearance of the final product. When cross-folding, at least the first fold must be parallel to the direction of the fibers.

Practical map folding techniques

Map folding is a particularly challenging application of this technique due to the need to maintain functionality while significantly reducing the format. The primary method is double parallel folding, dividing the sheet into four equal parts - ideal for topographical maps and technical projects.

Cross technique involves folding along one axis and then along a perpendicular one, forming a characteristic cross shape. For maps of larger formats, the following works well 16 quadrant method, dividing the surface into sixteen equal sections of about 15×18 cm each, which ensures convenient use while maintaining a compact size.

Best practices include numbering the squares before folding, kneading the folds on both sides for durability, and using a soft pencils for marking temporary lines. For topographic maps, consider strategically cutting on the horizontal line between selected quadrants, making it easier to navigate without having to completely unfold.

Modern technological solutions

Today's bookbinding industry offers advanced solutions to automate the folding process.

Akonda, specializing in providing complete solutions for binderies, offers a wide range of professional folding machines tailored to different needs manufacturing.

The offer includes cassette folders for standard folding and knife folders Ensuring the highest precision. Akonda The SF-415 and SF-490 models represent different levels of automation - from manual adjustment to fully automatic settings with programmable parameters. Akonda Advanced solutions like the SF-490 and Swift Speed Fold combine creasing and folding functions, enabling work with papers up to 400 gsm. Akonda

Automation of folding processes brings tangible economic benefits - tasks previously performed by five people in four hours can be completed by one person in thirty minutes, while maintaining the highest quality and precision of execution.

Summary for practitioners

Folding is a fundamental skill in modern printing, requiring knowledge of both the theory and practical aspects of execution.

It is crucial to understand industry terminology, the properties of different types of papers, and to adapt the technique to the specific application.

Professional folding requires taking into account the direction of the paper fibers, choosing the right method depending on the weight of the material, and using the right tools and techniques.

The investment in modern folding machines allows to automate processes while maintaining the highest quality standards, which is the key to competitiveness in the rapidly growing printing industry.