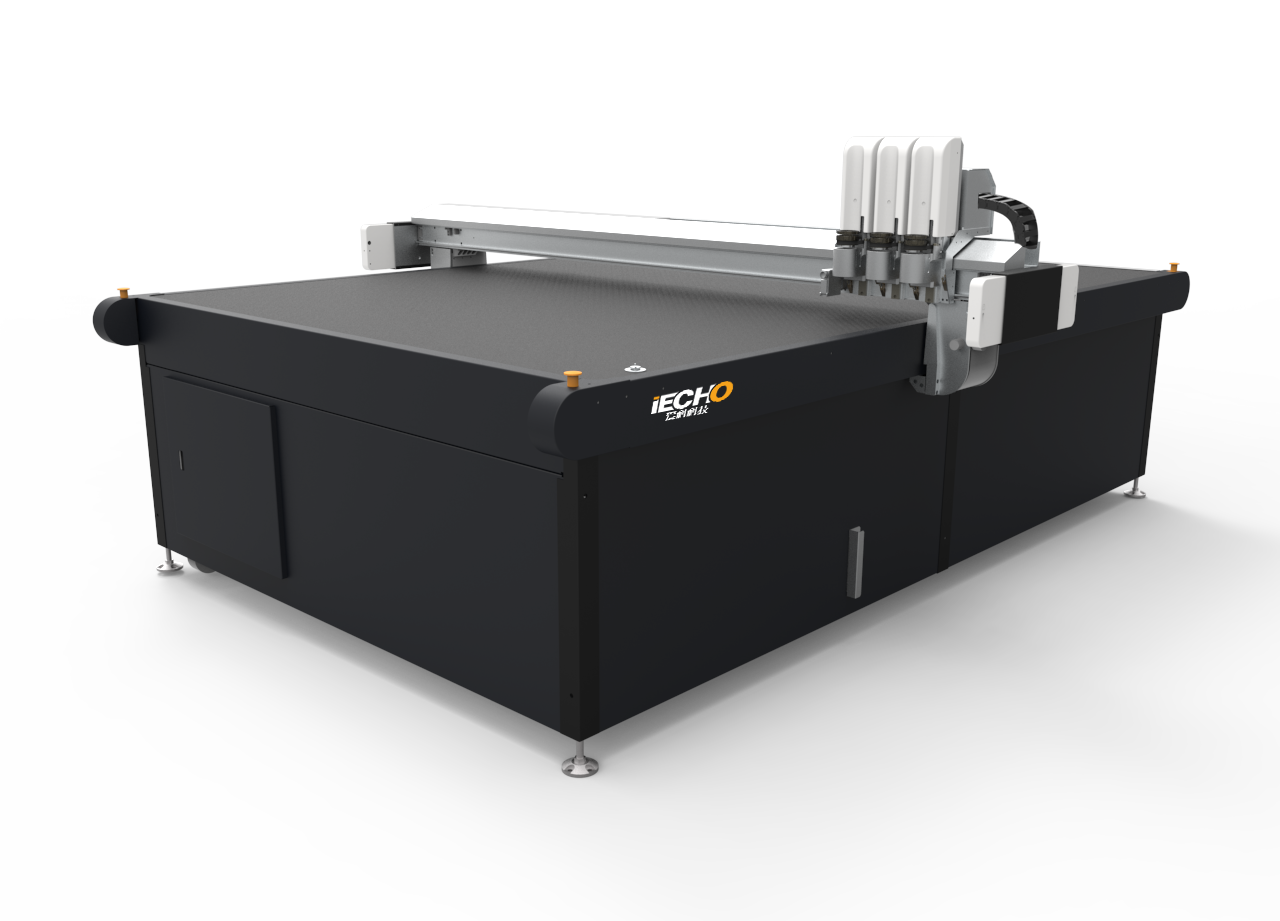

iEcho BK3 cutting plotters - high speed

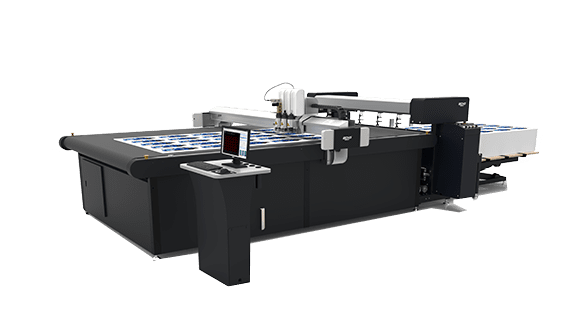

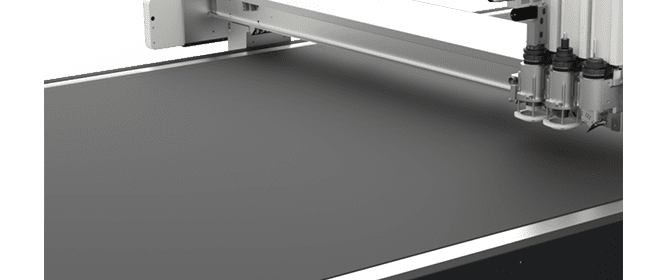

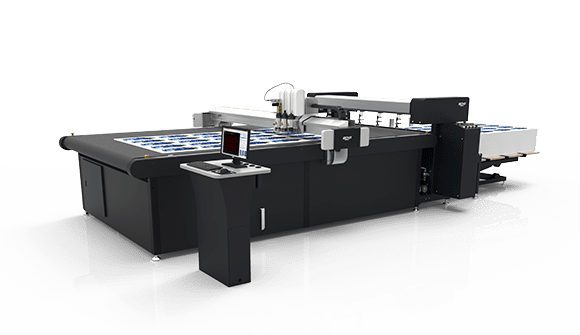

BK3 series plotters are high-capacity automatic cutting-big plotters with an optional automatic feeder. The aluminum table and the possibility of using 3 different modules make them a versatile solution especially used in the advertising and printing industries.

Features

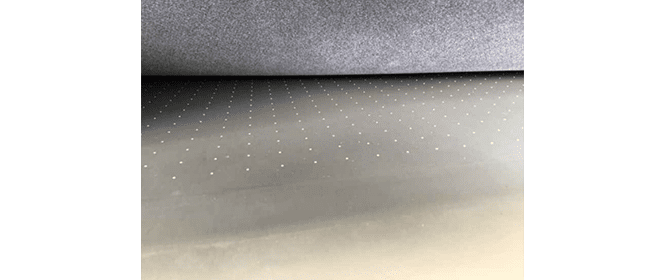

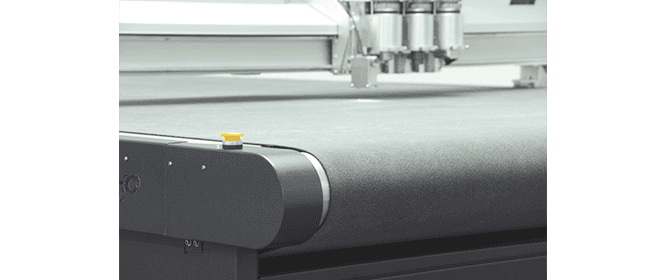

The under-suction used in the BK3 workbench can be turned on or off at any time to achieve a more dedicated work area with more under-suction power and less wasted energy. The power of the under-suction can be controlled.

Equipped with a zoned suction system, the aluminum table offers a more economical and sturdier hold on workpieces.

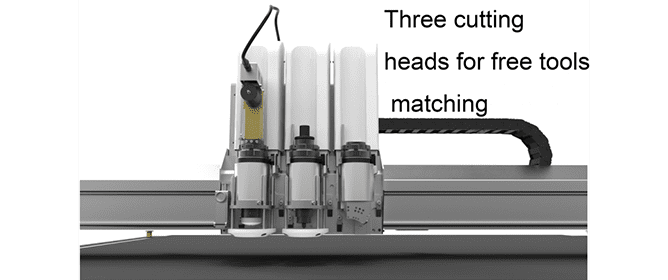

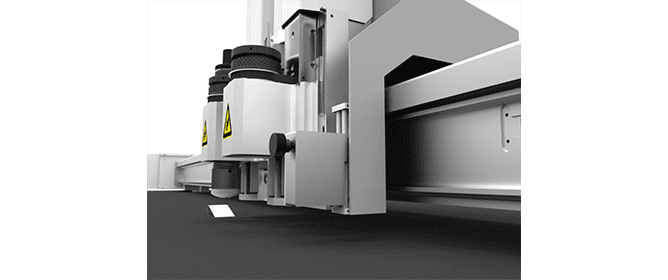

Possibility to install three heads equipped with different tools. The maximum cutting speed is 1.5 m / s (4-6 times faster than manual cutting), which significantly improves production efficiency.

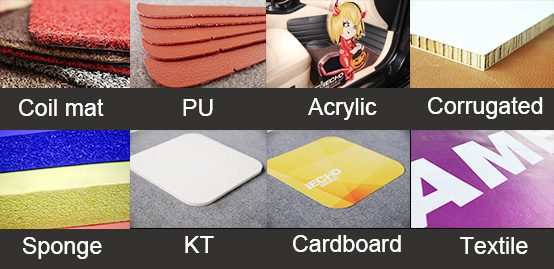

Types of materials to be processed

BK3 high precision digital cutting system can be realized by cutting, notching, milling, punching, creasing and marking with high speed and high precision. Thanks to its stacker-style automatic feeding and collecting system, it can carry out commissioned work quickly and unattended. The BK3 is suitable for sample making, short runs and mass production in the visual advertising, commercial printing and packaging industries.

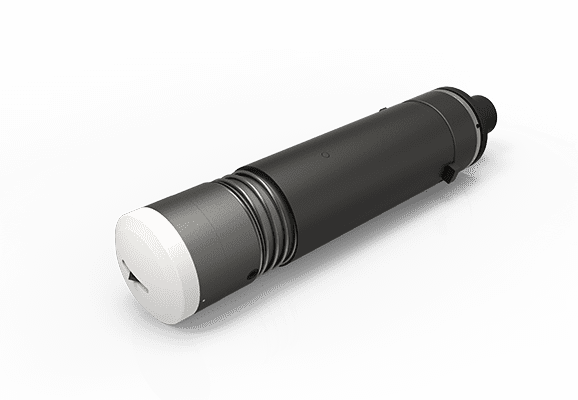

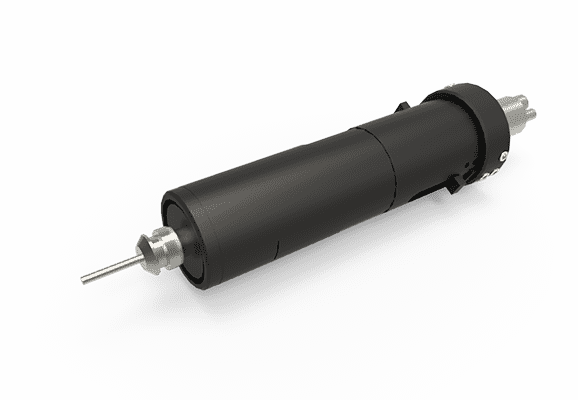

Universal UCT cutting tool - perfectly cuts through materials up to 5mm thick. Compared to other cutting tools, the UCT is the most cost-effective tool that provides the highest cutting speed and lowest maintenance costs. The spring-loaded protective sleeve ensures high cutting accuracy.

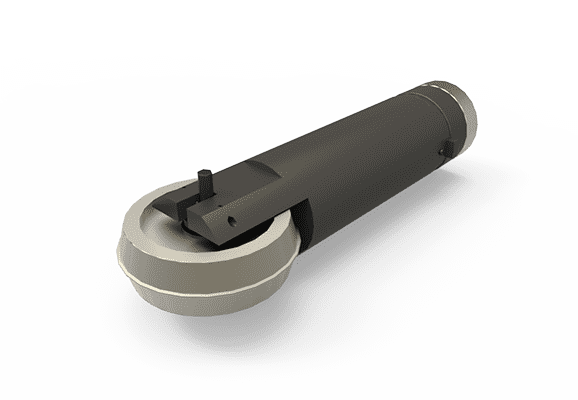

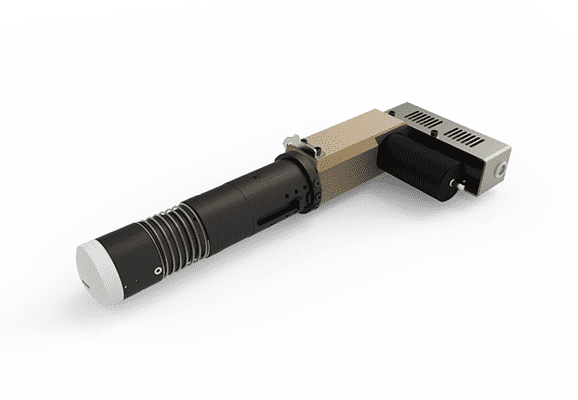

Creasing tool CTT - is used for creasing on corrugated materials. A selection of creasing tools allows for perfect creasing. Coordinated with the cutting software, the tool can cut corrugated materials along its structure or in the opposite direction to achieve the best creasing effect without damaging the surface of the corrugated material.

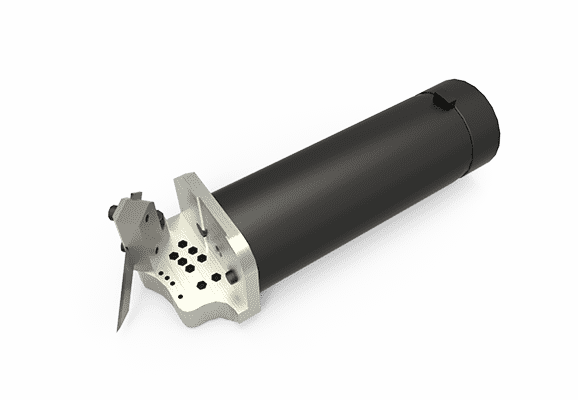

Specialized V-Cut (VCT) cutting tool - for V-shaped cutting on corrugated materials, can cut: 0 °, 15 °, 22.5 °, 30 ° and 45 °.

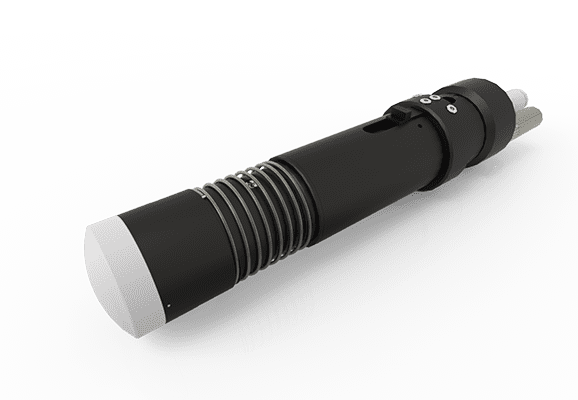

RZ routing tool - The RZ tool has a rotational speed of 60000 rpm. Driven by a high-frequency motor, the tool can be used to cut hard materials with a maximum thickness of 20mm. The IECHO RZ realizes the requirement of 24/7 operation. A customized cleaning device removes production dust and debris. The air cooling system extends the life of the blade.

Pneumatic oscillating blade (POT) - The POT is driven by compressed air. The tool, with a stroke of 8mm (frequency of 6000-8000rpm), is particularly suitable for cutting hard and compact materials. Equipped with different types of blades, the POT can produce different process effects. The tool can cut material up to 110 mm with specialized blades.

Kiss-cut tool (KCT) - is mainly used for cutting vinyl or self-adhesive materials. KCT allows the blade to cut through the upper part of the material without damaging the lower part. It allows for high cutting speed when processing the material.

Electric oscillating blade (EOT) - is ideal for cutting medium-density materials. Coordinated with different types of blades, the EOT is used to cut a variety of materials and is capable of cutting a 2mm arc. The stroke is 1mm with a frequency of 12000rpm.

System

Vaccum section control system

Continuous cutting system

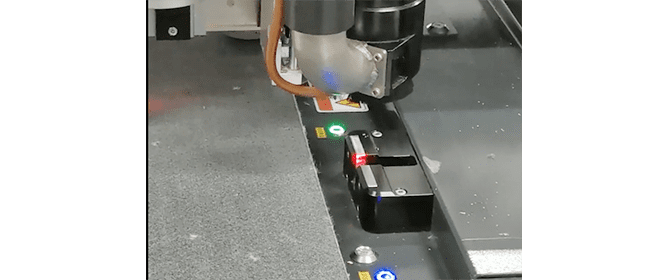

Automatic knife initialization

Precise automatic positioning system

Variety of options available

- roll to roll

- roll to sheet

- plate feeder

- stacker

Specification

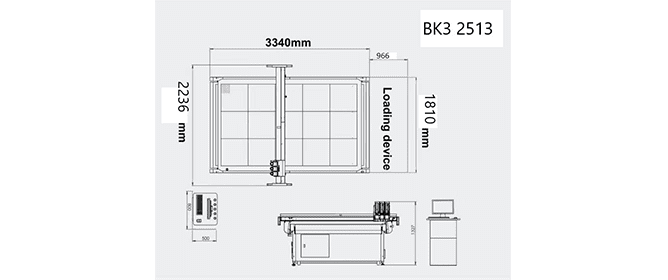

3 sizes available: 1700x1300mm; 2500x1300mm; 2500x1700mm

Max number of heads: 3

Max cutting thickness: up to 50mm (depending on the material, can be modified up to 110mm)

Max speed of cutting: 1500mm/s

Vacuum pump: 5,5kW; 7,5kW; 9kW

Other models of iEcho - TK4, BK4 series available.