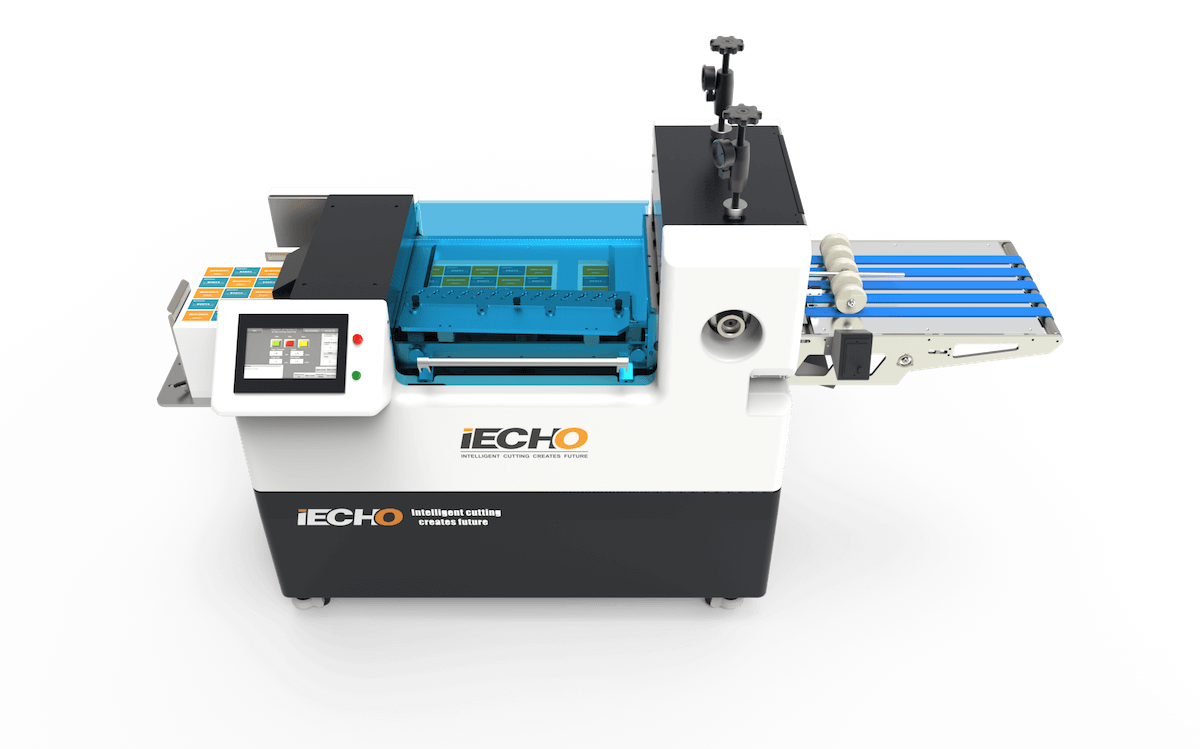

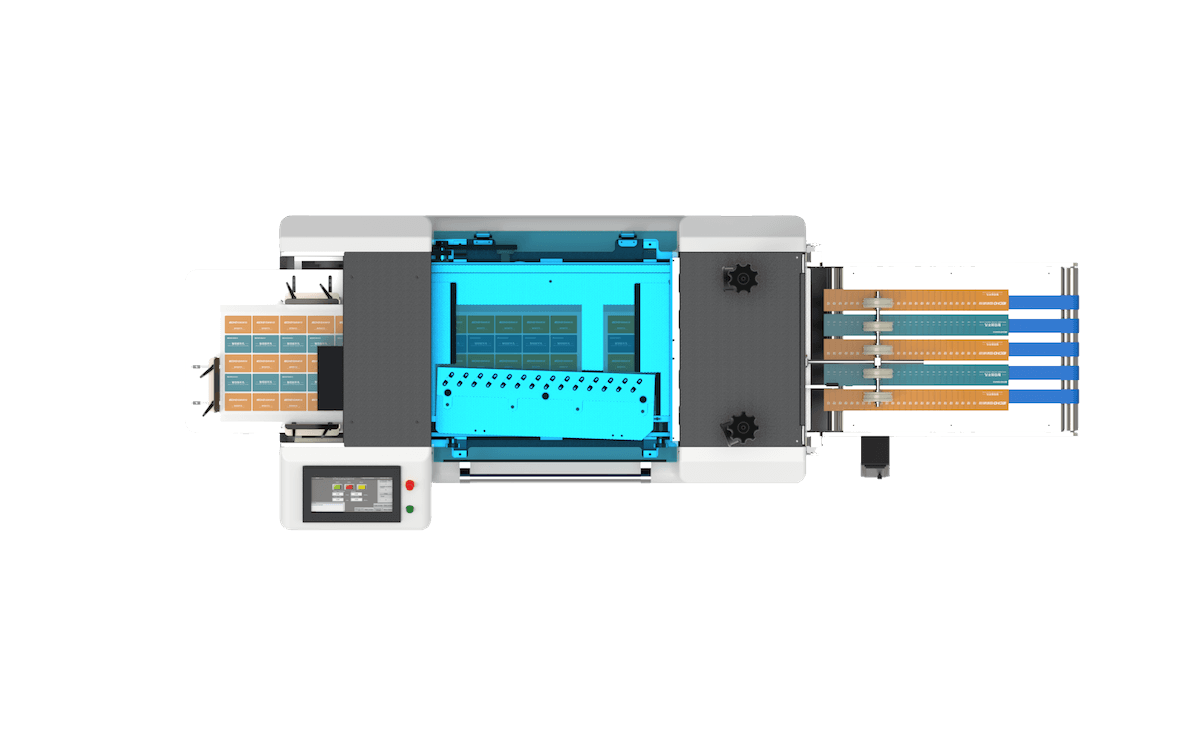

A new solution from iEcho's portfolio, the MCT rotary die-cutter is a high-performance die-cutting, notching and creasing device, working with a die-cutter mounted on a magnetic cylinder. It is ideal for medium and high-volume production of stickers, boxes, labels or cards with irregular shapes. The machine had its European premiere at the FachPack fair in Nuremberg and now is ready for presentation in the show-room of Akonda, the distributor of iEcho in Poland.

The iEcho MCT supports a maximum paper size of 508x355mm and operates at speeds of up to 5000 sheets per hour! The machine has an automatic paper feeder (picking using a belt, stack height up to 250mm) and a sheet positioning table, and the material is processed in a precision-made cylinder unit, where a die-cutter is mounted on the upper, magnetic cylinder. The distance between the cylinders is determined by the thickness of the material being processed. MCT rotary barbell has an openwork separation module that drops into the box under the belt on the lining, resulting in finished blanks. The machine covers an area of 2 square meters and is easy to transport thanks to its small footprint, but its compact size does not exclude a multitude of applications. The MCT has a convenient touch screen and intuitive software. The machine is designed to allow safe replacement of the magnetic die-cutter by the operator and thanks to the intelligent paper feeder, the paper is always precisely aligned.

- "MCT is widely used for self-adhesive stickers, wine labels, clothing tags, playing cards and other products, also used in the apparel or electronics industry. The downloaded sheets are leveled to the operator's side to ensure the greatest repeatability, precision of work and, importantly for our customers, no matter what type of paper the machine works on."

-assures Dominik Szulim, co-owner of Akonda.

- "It is also important that the desired shape is cut by a punch located precisely on a high-speed magnetic cylinder, which makes it possible to perform a variety of punching processes such as full cutting, notching, perforating and creasing."

iEcho is known in Poland as a leading manufacturer of cutting and binding plotters. The iEcho PK series equipped with an automatic sheet feeder in formats from 60x40cm, 73x55cm and 120x90cm has already been implemented in dozens of printing houses across the country. The creasing and cutting plotters produce stickers, labels, and boxes starting from 1 piece, based on a digitally loaded PDF or DXF file. The iEcho portfolio also includes larger table-top creasing plotters of the BK3/BK4 and TK4 series - for flat materials (composites, MDF, PVC, natural leather) and the VK series for roll materials (advertising, home-decor and textiles). The plotters of both series can be configured in sizes from 120x160cm to 330x550cm with a wide range of available tools, such as active, oscillating, rotary cutters or 300W or 1800W milling machines.

Mariusz Bogucki, head of Akonda's commercial department, points out one more aspect.

"Our customers are reassured because detailed training on the machine's operation is provided with each installation. The service support provided by our technical department is not insignificant, and this gives a great sense of security. Besides, the manufacturer itself has already made sure that the use of the rotary die or plotters is simple and intuitive."

With innovation embedded in the organization's DNA, iEcho is a company that fulfills orders for several thousand cutting plotters a year, invests and is listed on the Shanghai Stock Exchange. The manufacturer's staff consists of nearly 300 specialists and the production of most components takes place within the company's nearly 60,000 square meters. Akonda is iEcho's most active partner, with the largest number of plotters delivered in Central and Eastern Europe!