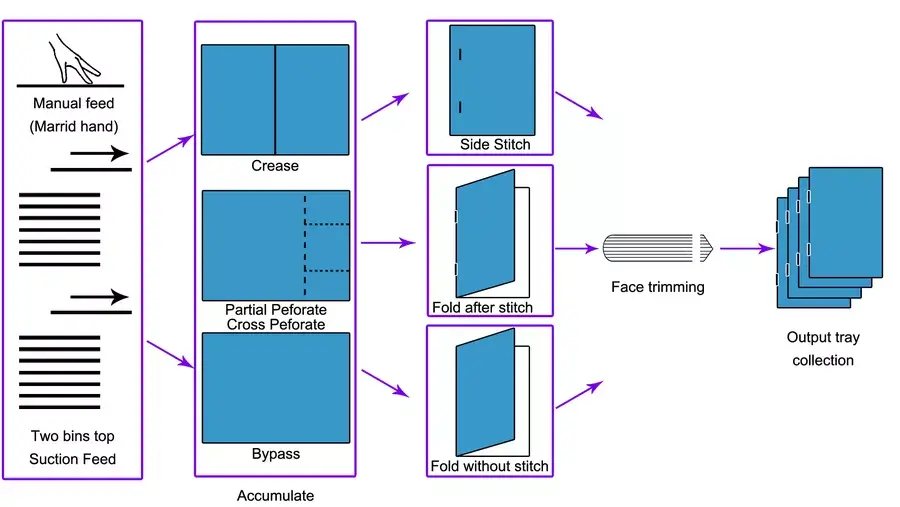

Ausjetech MFB integrated booklet making system - from sheet to finished product

Ausjetech multifunctional booklet making system MFB is a complete, fully automated production line encapsulated in a single, compact machine. It is designed to eliminate all manual steps and bottlenecks in the booklet making process. MFB autonomously performs the entire process: from retrieving covers and measures from two separate trays, by creasing and perforation of covers on the fly, up to sewing, folding and final front trimming. With advanced features such as wire sewing, progressive creasing and full automation of settings from the touch panel, the MFB transforms stacks of printed sheets into perfectly finished, high-quality brochures, catalogs and manuals, ensuring unrivaled productivity and repeatability.

Key features and benefits

📚 Two-bin feeder with cover creasing

At the heart of the system is a unique feeder with two independent trays: an upper tray (100 mm) for covers and a lower tray (350 mm) for center sheets. What's key, the upper feeding track is equipped with an integrated creasing and perforating module. This means that the covers are perfectly prepared (creased or perforated) even before they are joined to the center, which guarantees the highest quality and eliminates the risk of cracking the spine.

🧵 Professional wire sewing with Deluxe heads

MFB uses professional sewing heads that use the following as consumables steel wire from the spool, rather than ready-made staples. This solution drastically reduces the unit cost of each booklet, which is extremely important for large print runs. The latest generation of "Deluxe" heads have been optimized to work with digital prints, ensuring strong and reliable stitching every time.

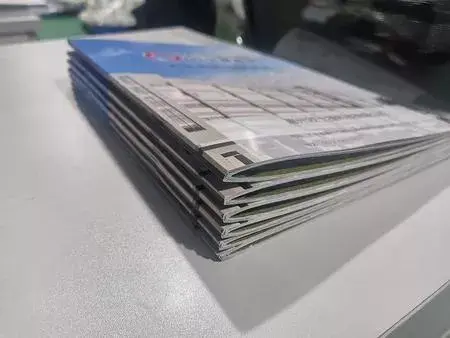

✨ Progressive function and perfect square back

The patented progressive creasing feature intelligently moves the crease line on each successive sheet of the insert. As a result, when folded, the booklet forms a perfectly flat, square back, resembling a glued binding. Publications finished in this way lie flat, do not damage when opened and look extremely professional, even when using high weight papers.

🤖 Full automation and intelligent features

Forget about manual adjustments. All key settings - side and back guides, trimmer cutting position, creasing roller pressure - happen fully automatic from the touch screen. Additional features, such as an ultrasonic double-take sensor, a tag reading system ("Read Mark"), and a "Hand Married" option for manual sheet feeding, give full control and flexibility in production.

✂️ Integrated front trimmer with cuttings ejection

The final step in the fully automated process is face cutting. The stitched and folded booklet goes to the integrated T33 trimmer, where a heavy-duty knife makes a perfectly smooth cut. What's important, cuttings are automatically removed outside the machine by means of a conveyor belt, which allows uninterrupted operation without having to stop production to empty the container.

Ideal application in manufacturing

Thanks to its versatility, MFB is ideal for producing a wide range of top-quality materials:

- High-quality magazines and catalogs of luxury products

- Professional restaurant menus and price lists

- Children's books and travel guides

- Manuals and manuals with a perfectly flat back

- Personalized works and low-volume prints

Detailed technical specifications

| Input sheet format | Min: 148.5 x 210 mm Max: 330 x 480 mm |

| Output format (saddle stitching) | Min: 148.5 x 80 mm Max: 330 x 240 mm |

| Output format (side stitching) | Min: 268 x 112 mm Max: 330 x 247 mm |

| Feeder capacity | Top tray (covers): 100 mm Bottom tray (centers): 350 mm |

| Sewing thickness | 2-25 sheets 80 gsm |

| Thickness of cut (trimmer) | Up to 48 sheets of 80 gsm + 128 gsm cover sheet |

| Sewing heads | 2 (latest generation "Deluxe" for digital printing) |

| Consumable material | Steel wire in spools |

| Creasing strips | Standard: 1.0 mm Options: 0.6, 1.2, 1.4 mm |

| Settings | Fully automatic (guides, roller pressure, cutting position) |

| Expansion options | Cross perforator, linear perforator (also partial), barcode reader |

| Accuracy | +/- 0.5 mm |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.pl, we understand that implementing such an advanced system is a strategic decision. That is why we provide full technical support at every stage - From needs analysis and professional configuration, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables (wire, knives) and spare parts.