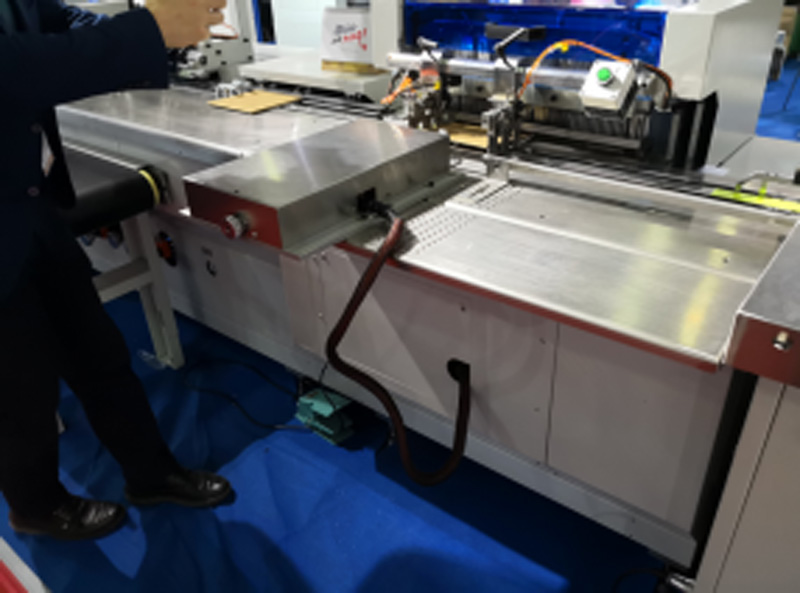

Automatic wire spine binding line PBW580

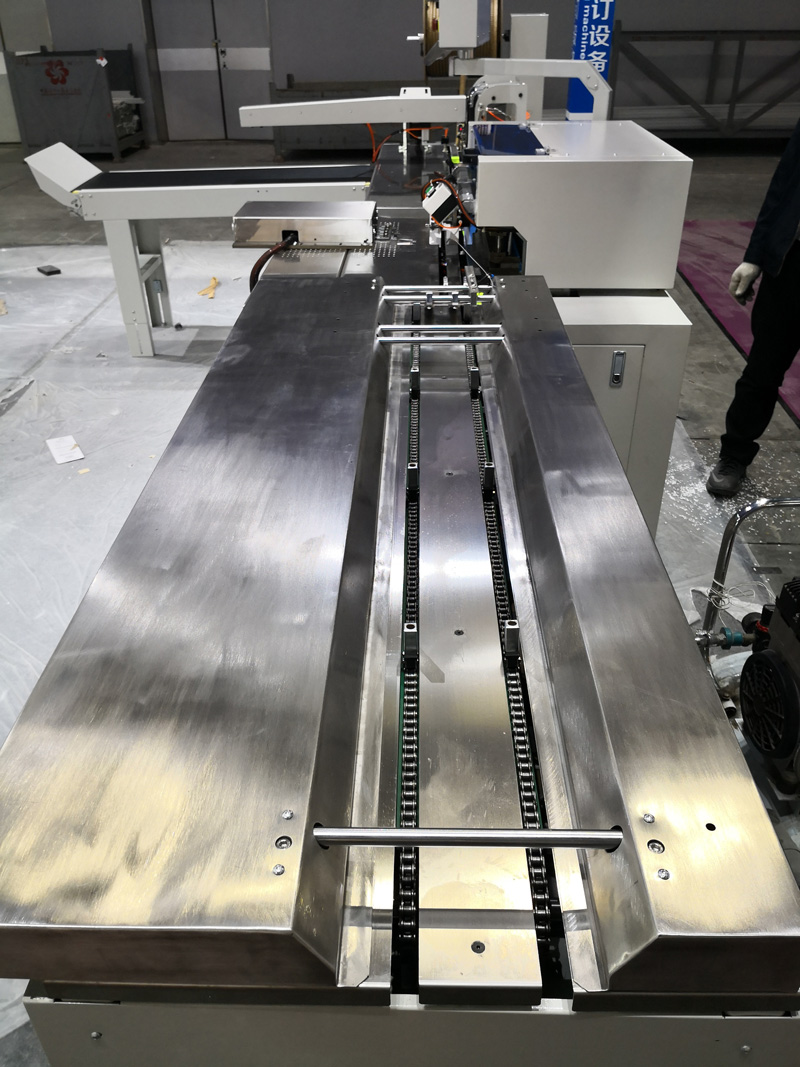

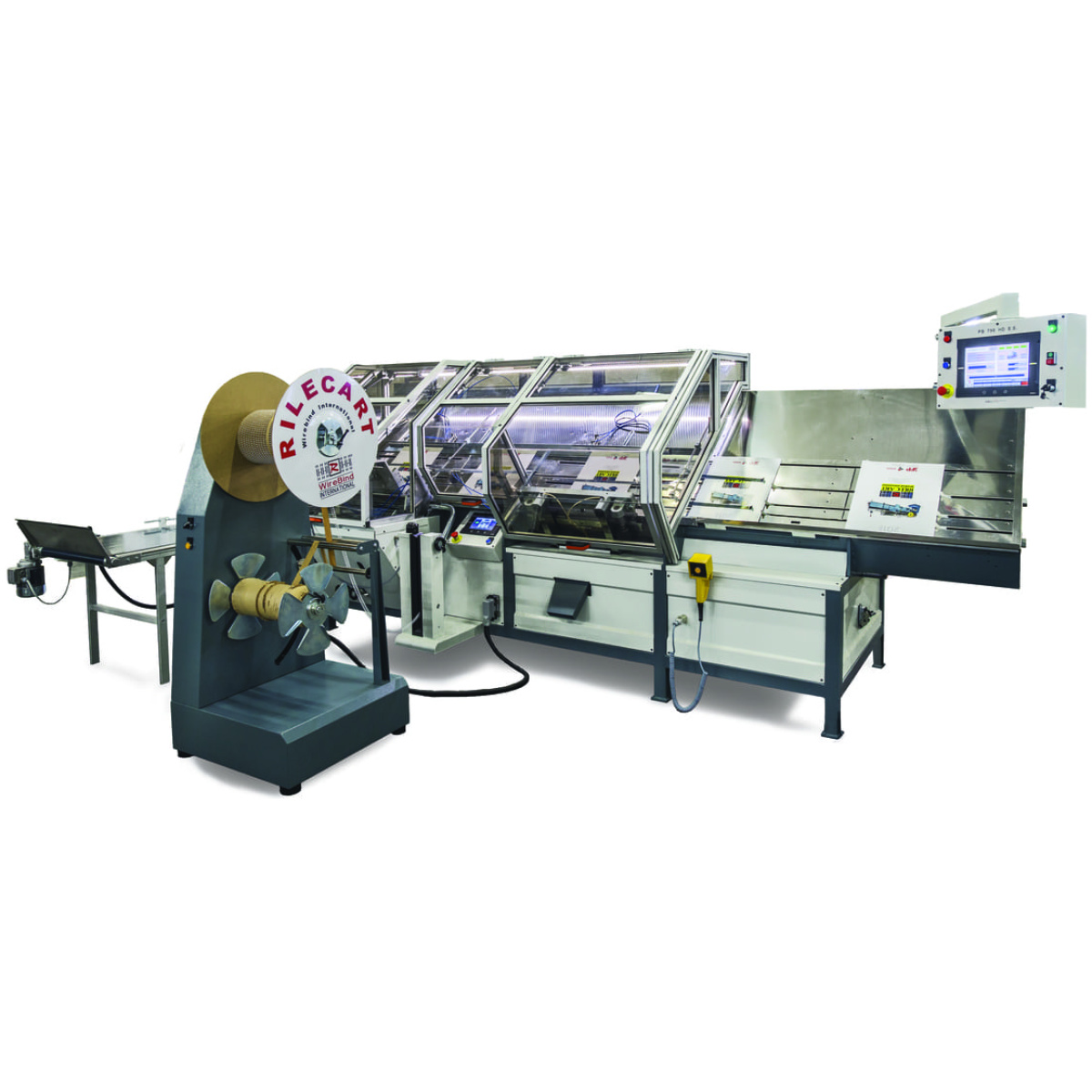

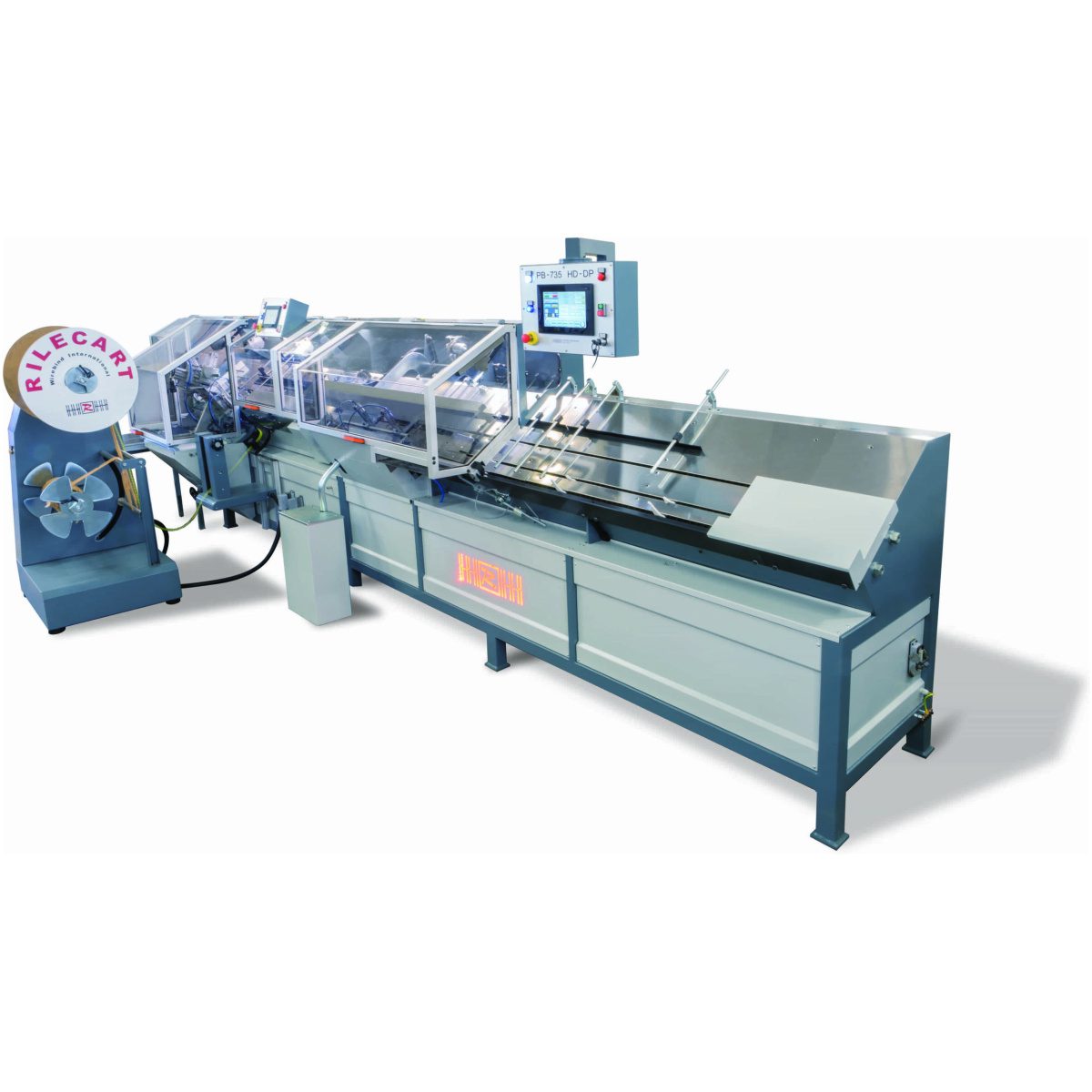

Line PBW580 is an advanced solution that revolutionizes the production of wire-bound (wire-o) materials. It is a complete system that, in a single, fully automated cycle perforates and closes the wire spine, eliminating the need for two separate machines and manual block handling. Designed for maximum efficiency, the PBW580 drastically reduces labor costs and speeds up the processing of orders for notebooks, desk calendars and wall calendars. It's an ideal investment for printers and binderies that want to automate and optimize wire binding production.

The machine comes in configurations - with or without a manual application module.

Key features and benefits

⚙️ Two machines in one: perforation and in-line binding

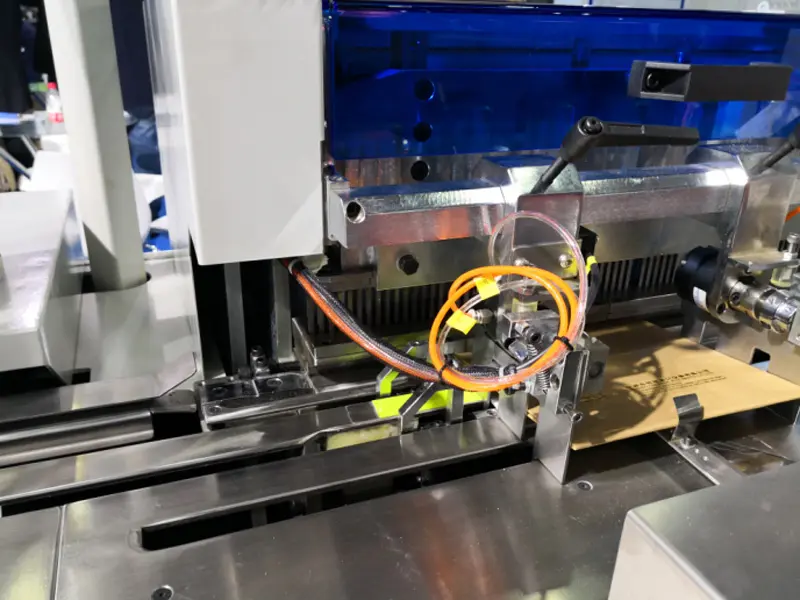

The biggest advantage of the system is the integration of the perforation and spiral closing process. The operator feeds the finished blocks, and the machine automatically perforates them, transports them to the binding section and closes the spine. What's more, the modules can work independently - as a perforating machine alone or a closing machine alone.

📚 Production versatility: notebooks, desk and wall calendars

The PBW580 line is extremely flexible. It allows the production of standard notebooks, desk calendars (of the "pyramid" type), and, thanks to an optional hanger feeder module, also fully automatic production of wall calendars with automatic hanger insertion.

🤖 Intelligent automation and ease of use

The operation of the machine is managed from a touch screen. Among other things, the operator can set after how many pieces the finished products are to be automatically pushed back on the receiving belt, which facilitates packaging. The machine is characterized by high productivity, allowing the binding of up to 1,500 pieces per hour.

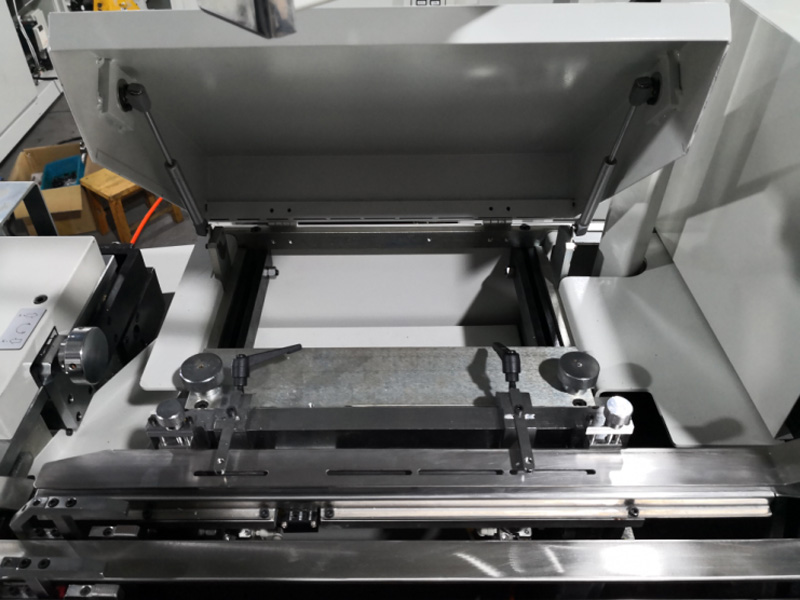

🛠️ Flexible punching system and large format

The machine handles large paper formats up to 580 x 800 mm and can punch material with a total thickness of up to 15 mm in several cycles. The modular punch bar allows the position of the perforating segments to be changed, giving great flexibility for unusual projects.

See the PBW580 line in action

Notebook production

Production of desk calendars

Production of wall calendars with pendant

Detailed technical specifications

| Model | PBW580 |

| Speed | 600 - 1500 pieces / hour dependent on material and operator |

| Maximum paper format | 580 x 800 mm (without overlay module) |

| Minimum paper format | 120 x 105 mm |

| Maximum binding/punching width | 580 mm |

| Maximum punch thickness | Up to 15 mm (in 5 cycles) |

| Supported spine diameters | 1/4″ – 3/4″ |

| Required air pressure | 5 - 8 kgf |

| Power supply | 380V (3 phases) |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.co.uk, we know that buying a production machine is a strategic decision. That's why we provide full technical support at every stage - From professional consulting, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables (wire backs, hangers) and spare parts.