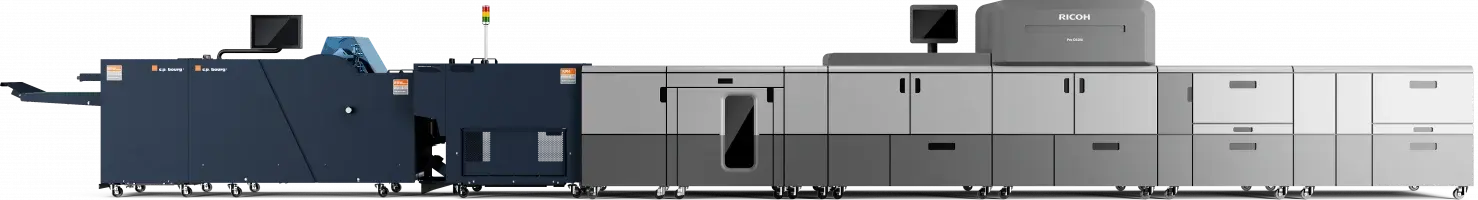

Universal booklet making platformBourg BBM with BSF feeder

Brochure system Bourg Booklet Maker (BBM). is much more than a machine - it is a complete, modular finishing platform, designed to become the heart of the modern print shop. Its unique architecture allows it to operate in two, strategic modes: ONLINE (inline), in full automation with printing machines, and OFFLINE As an independent, ultra-efficient position. With official cooperation with all leading manufacturers of digital machines, the Bourg system guarantees seamless integration and paves the way for maximizing productivity, regardless of your machine fleet. With speeds up to 5000 booklets per hour and handling sheets up to 600 x 370 mm, the Bourg BBM is the answer to the most demanding production needs.

Two modes of operation - full production flexibility

🚀 ONLINE mode: integrated automation

Unleash the full potential of your printing machine. In inline mode, the Bourg system becomes an integral part of your production line, creating a "roll/sheet to finished booklet" process without operator involvement. It's ideal for high-volume and express jobs. The system is fully compatible with machines from market leaders such as:

- Canon

- Ricoh

- Xerox

- Konica Minolta

- HP Indigo

- Kodak

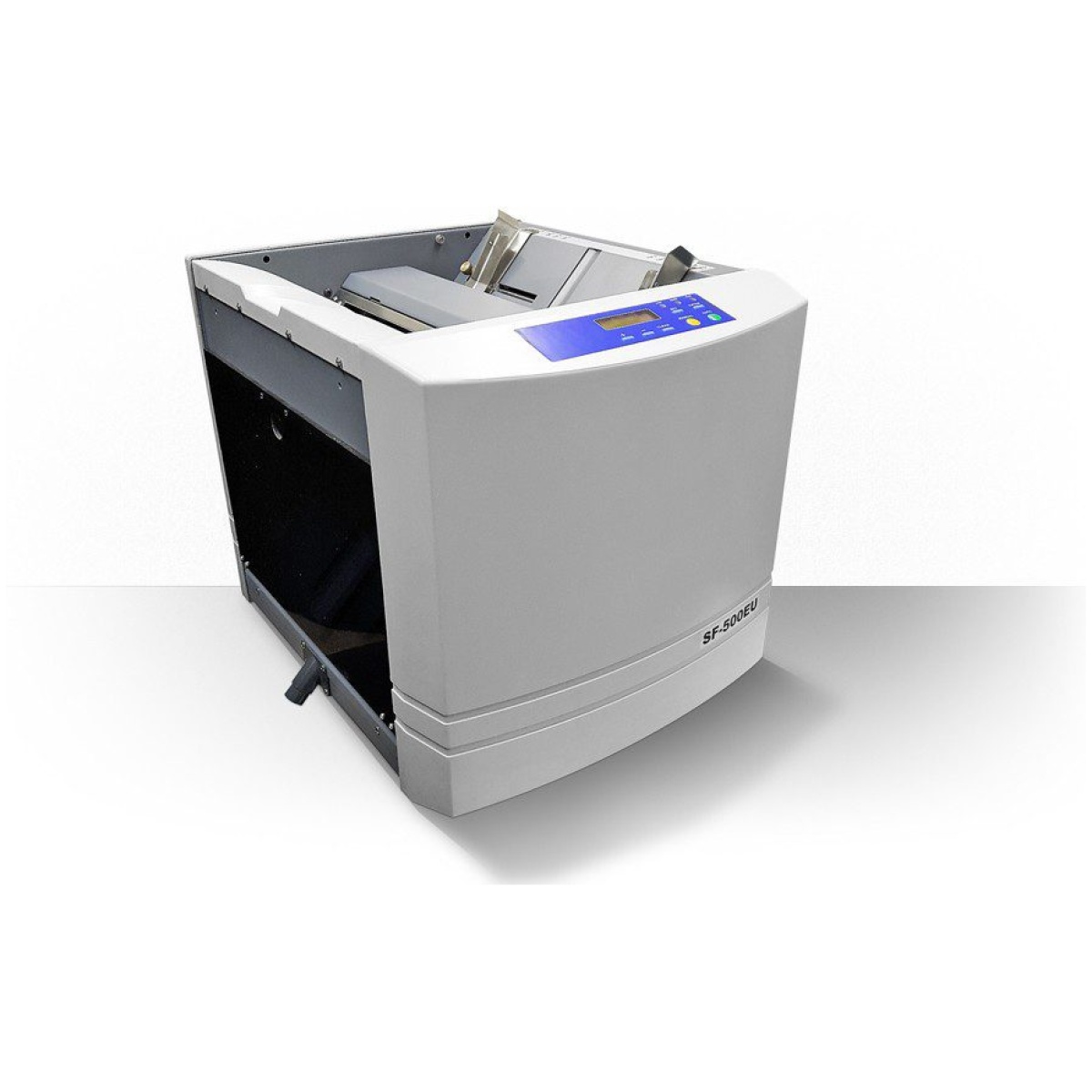

OFFLINE mode: unparalleled versatility

The heart of offline operation is the powerful feeder Bourg Sheet Feeder (BSF). This configuration allows you to handle orders from a wide variety of machines - digital, offset or outdoor. It makes it possible to maximize the uptime of each printing machine, without depending on the speed of finishing. This is an ideal solution for printers with a diverse fleet of machines and a wide range of orders.

Key features and benefits

💨 Top-of-the-line BSF feeder

Based on more than 30 years of experience, the BSF suction feeder reliably picks up a wide range of weights (60-350 gsm) at speeds of up to 18,000 sheets/hour. It features two feeding stations - drawer for smaller expenditures and high stack (500 mm) for long jobs, which guarantees continuous offline production.

🤖 Intelligent automation and control

Ergonomic, tactile graphical interface (GUI) with an icon system makes operation intuitive. All job settings are stored in memory for tool-less and instant changeover. A barcode system and JDF/JMF support ensure work integrity and automation.

📚 Square Edge option for perfect ridges

With the optional module Bourg Square Edge (BSE), finished brochures get an elegant flat spine, resembling a perfect binding. This is ideal for producing premium materials that will stand out from the competition and stack perfectly.

🛠️ Full modularity with BPM module

The system can be expanded with a module Bourg Preparation Module (BPM), which allows automatic creasing, bleed cutting, perforation and creation of multi-use jobs (2-up/4-up) in one pass, before the sewing and folding process.

Detailed technical specifications

BSF sheet feeder (Offline mode)

| Maximum speed | 18,000 sheets/hr (A4, 90 gsm) |

| Paper weight | 60 - 350 gsm |

| Paper format (drawer/bypass) | Min: 203.2 x 120 mm Max: 660.4 x 364 mm |

| Paper format (high stack) | Min: 203.2 x 177.8 mm Max: 660.4 x 364 mm |

| Feeder capacity | Drawer: 140 mm High stack: 500 mm |

| Power supply | 230V ±10%, 50Hz, 6.5A |

| Power consumption | Operating mode: 760 W Standby mode: 160 W |

| Noise level | 75 dB |

| Dimensions (L x W x H) | 133 x 91.3 x 131.6 cm |

| Weight | 470 kg |

BBM brochure module

| Maximum efficiency | Up to 5,000 booklets/hour. |

| Thickness of the booklet (saddle stitching) | Up to 12 mm (up to 30 sheets of 80 gsm + cover) |

| Block thickness (top/side sewing) | Up to 6 mm (up to 60 sheets of 80 gsm) |

| Input format (saddle stitching) | Min: 180 x 119 mm Max: 600 x 370 mm |

| Output format (saddle stitching) | Min: 70 x 119 mm Max: 300 x 370 mm |

| Input format (top/side sewing) | Min: 119 x 170 mm Max: 300 x 370 mm |

| Frontal cutting (trimming) | 2 to 25 mm |

| Options | Square Edge (BSE) module, Hohner heads (2 or 4, loop option), Creasing, cutting and perforation (BPM) module, JDF/JMF automation |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.pl, we understand that implementing such an advanced system is a strategic decision. That is why we provide full technical support at every stage - From needs analysis and professional configuration, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables (staples, knives) and spare parts.