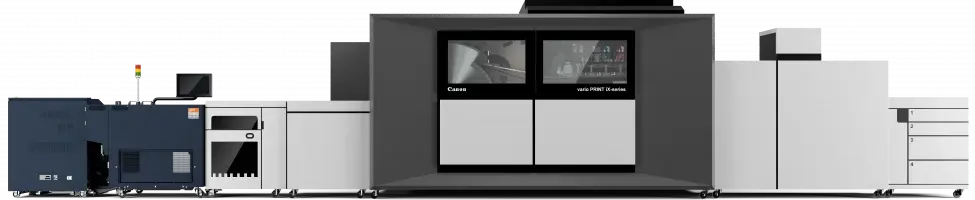

C.P. Bourg modular sheet preparation system (BSF + BPM + BPS)

Introducing the revolutionary C.P. Bourg system, a complete and fully automated solution that provides the missing link between printing and finishing. This modular line, consisting of BSF feeder, BPM preparation module and BPS smart stacker, was created to eliminate the time-consuming and error-prone manual cutting of stacks on a guillotine. The system transforms printed sheets in a single pass into perfectly even, precisely cut and sorted stacks of book blocks, ready for further processing. Thanks to the ability to work in the inline with machines from leading manufacturers, and flexible operation of the offline, it is the most versatile tool for automating production in a modern printing plant.

Three modules - one automated line

The C.P. Bourg system consists of three specialized modules that can work together to form a fully integrated production line:

1. BSF feeder - Offline starting point

The heart of offline operation is the powerful feeder Bourg Sheet Feeder (BSF). With a dual loading system (a drawer for short runs and a 500mm high stack for long jobs) and compatibility with the carriages of most digital machines, the BSF allows flexible and efficient feeding of sheets from different sources for further processing.

2. the BPM module - the heart of the system

Bourg Preparation Module (BPM) is the module where all the "magic" takes place. It prepares the sheets for final format, performing such operations as: rotating, pitch cutting, utility cutting (2-up/4-up), professional knife creasing and cross perforation. He is the one who replaces the work of the guillotine and the operator.

3rd Stacker BPS smart final

Bourg Perfect Stack (BPS) is much more than a simple stacker. It picks up prepared sheets and stacks them in perfectly even stacks with offset capability for order separation. Thanks to the "unload while run", the operator can pick up the finished stack without interrupting the machine, ensuring maximum production continuity.

Key features and benefits

🔗 Full Inline integration or Offline flexibility

The system is designed to work in any production environment. It can be combined into a single, fully automated line with printing machines from leading manufacturers or work as an independent island, handling orders from the entire machine park.

📈 Revolutionary 2-UP and 4-UP workflows

Reap the full potential of SRA3 sheets. The BPM module automatically cuts printed sheets into 2 or 4 uses and then stacks them. This dramatically increases productivity, reduces "click" costs and automates the production of smaller formats such as A5 books.

🤖 Flawless production through automation

An intuitive touchscreen interface (GUI) allows tool-less and quick changeover. An optional barcode reader guarantees work integrity and automatically loads settings. The entire process minimizes operator intervention, reducing the risk of errors and material waste.

🏗️ Scalability and expansion

The C.P. Bourg system grows with your company. The line can be expanded with a second BPM module (for 4-up operation in a single pass) or a second BPS stacker, which, thanks to its "auto-switch" function, allows uninterrupted operation at maximum load.

Detailed technical specifications

BSF sheet feeder (Offline mode)

| Maximum speed | 18,000 sheets/hr (A4, 90 gsm) |

| Paper weight | 60 - 350 gsm |

| Paper format | Min: 203.2 x 120 mm Max: 660.4 x 364 mm |

| Feeder capacity | Drawer: 140 mm High stack: 500 mm |

BPM preparation module

| Production speed | Up to 300 sheets/min (A4) / up to 200 sheets/min (A3) |

| Slope cutting (up/down) | Range: 4 to 100 mm Tolerance: 0.4 mm |

| Creasing / Microperforation | Position tolerance: 0.4 mm Weight: 60 - 350 gsm |

| Cutting back on utility | Position tolerance: 0.4 mm Weight: 60 - 350 gsm |

Stacker BPS

| Maximum stack height | 250 mm |

| Weight (2-up flow) | 60 - 350 gsm |

| Weight (4-up flow) | 60 - 170 gsm |

| Sheet format at the entrance to the BPS | Min: 225 x 160 mm Max: 500 x 364 mm (without cutting in BPM) Max: 300 x 364 mm (with cutting in BPM) |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.pl, we understand that implementing such an advanced system is a strategic decision. That is why we provide full technical support at every stage - From needs analysis and professional configuration, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables and spare parts.