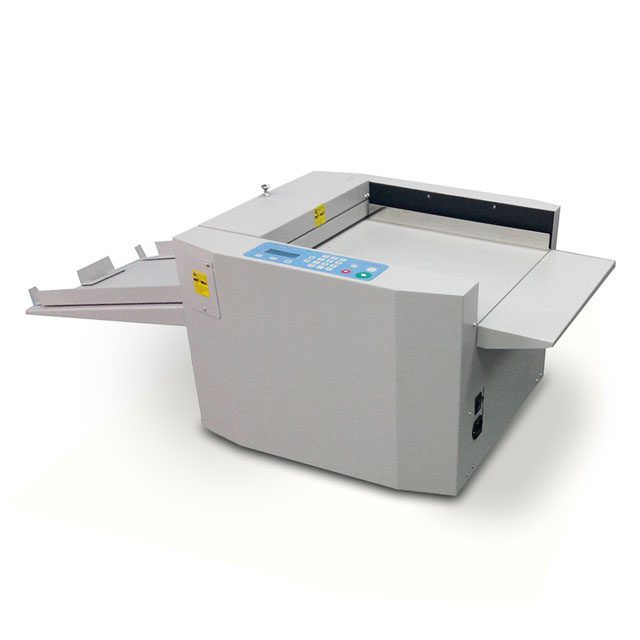

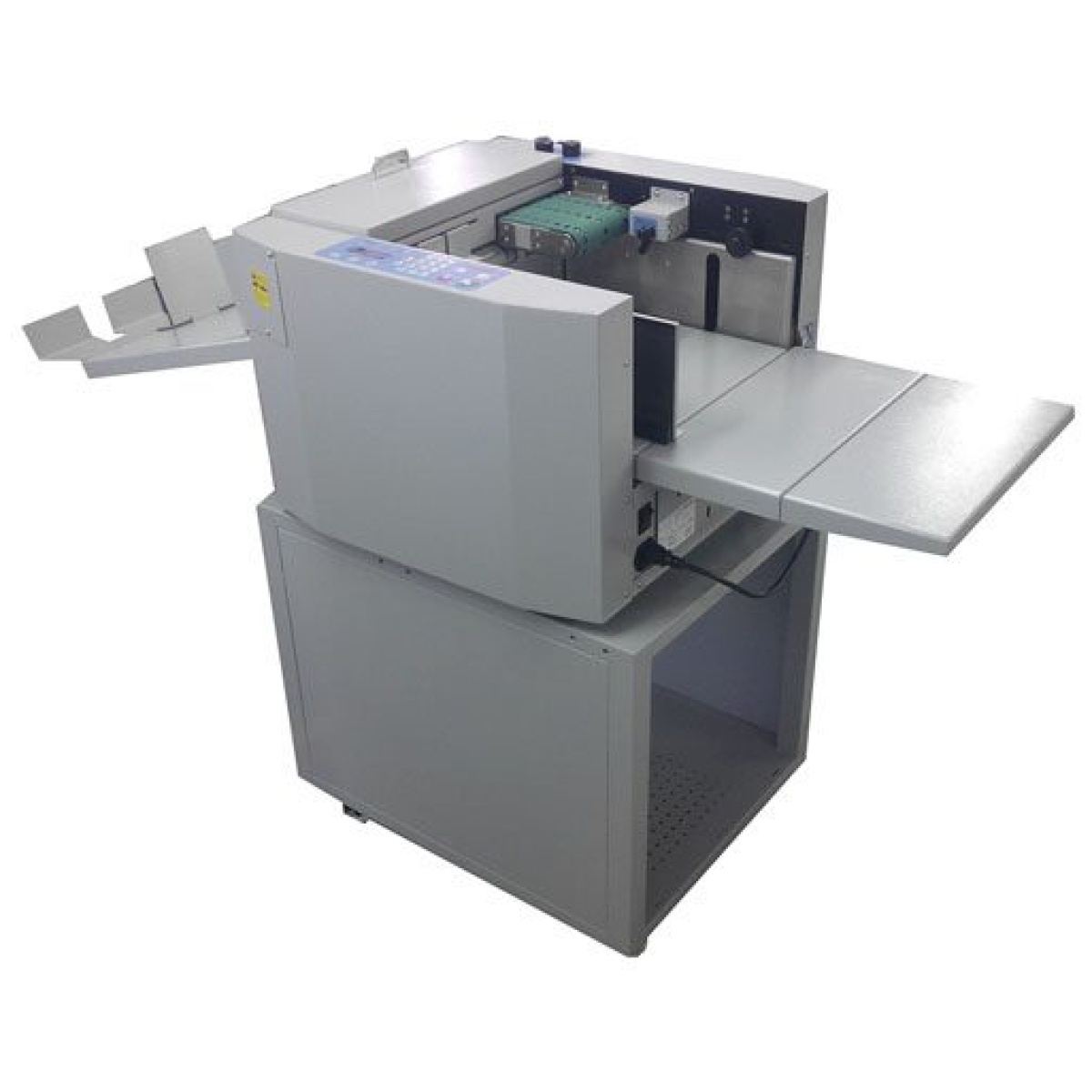

Swift 333 hand creasing machine and Swift 336 hand creasing machine - ideal solutions for digital printers

The Swift 333 manual creasing machine and the Swift 336 manual creasing machine are versatile devices dedicated to digital printers and print-room service centers. Creasing papers from 100 to 350 gsm has never been easier. The Swift 333 and Swift 336 effectively eliminate the problem of paper and ink cracking when creasing, making it an ideal choice for processing more difficult materials.

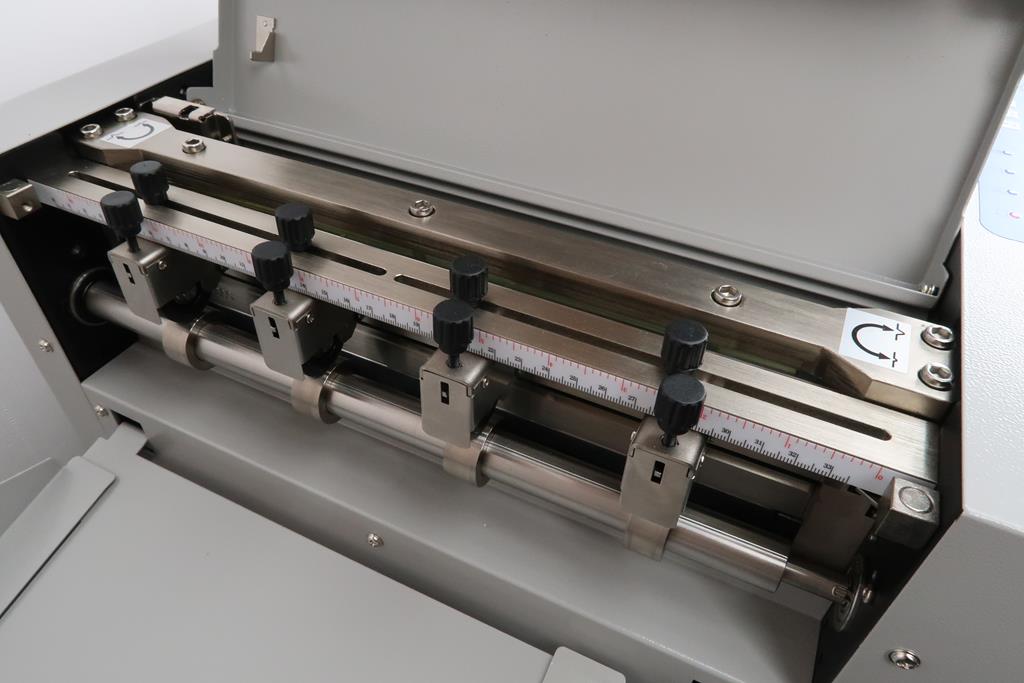

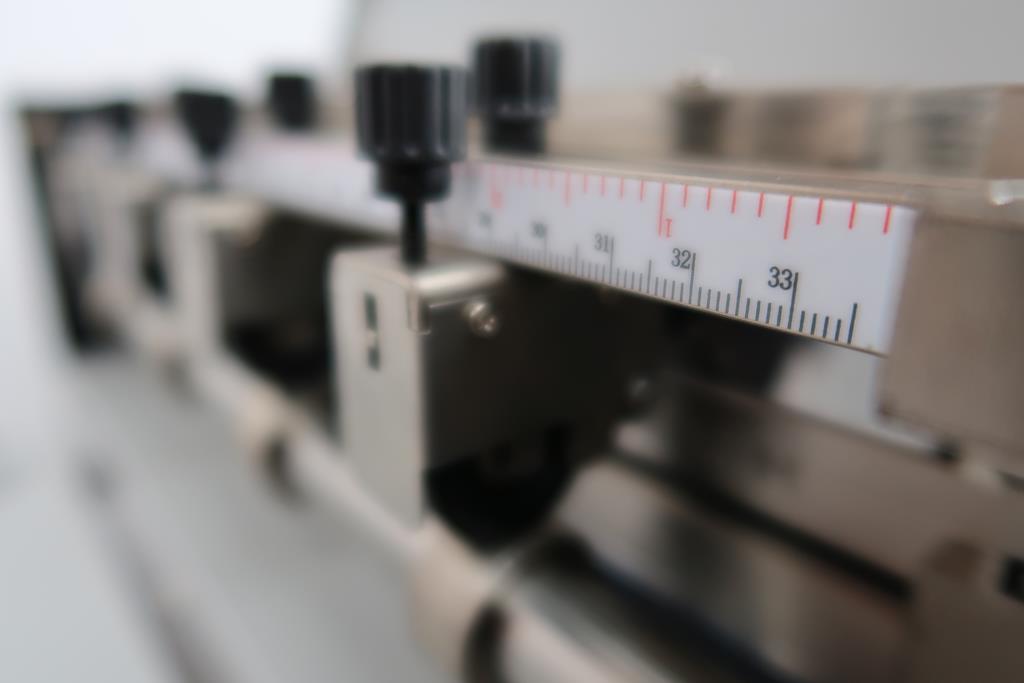

With manual sheet feeding and interchangeable creasing and perforating tools, the machine provides full flexibility to adapt to individual production needs. The maximum sheet size of 330 x 900 mm and the ability to make up to 32 creases on a single sheet ensure that it can handle the most demanding projects.

Swift 333 and Swift 336 hand creasing machine - product features:

- Weights range: 100-350 g/m² (creasing), 100-250 g/m² (perforation)

- Minimum sheet size: 90 x 50 mm

- Maximum sheet size: 330 x 900mm

- Maximum number of bigs in one pass: 32

- Convenient to use programmer with membrane keypad.

- Progressive creasing option - i.e. a programmer mode that allows you to conveniently create a booklet spine imitating perfect binding (cover with two creases)

Differences between Swift 333 and Swift 336 hand creasing machines.

There are no visual differences in the external view or functionality of the programmer.

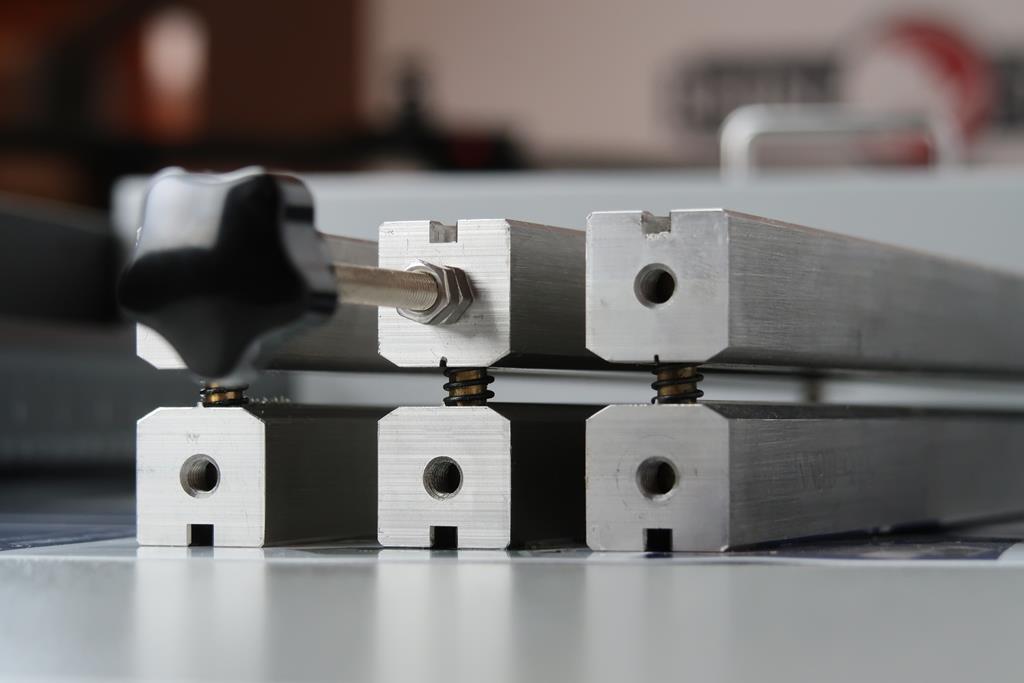

The only difference is that the Swift 333 creasing machine has a creasing bar of only 1mm width, which is interchangeable with a perforating bar. The Swift 336 creasing machine, on the other hand, has replaceable steel creasing strips - 1mm is standard, plus optional 0.6mm (recommended for papers up to 200g/m2) and 1.4mm (recommended for papers from 300g/m2) - selecting the appropriate creasing strip thickness allows you to achieve better creasing quality. The Swift 336 creasing machine also has the option of installing a perforating strip.

The Swift 333 and 336 manual creasing machine is the perfect combination of precision, flexibility and ease of use.