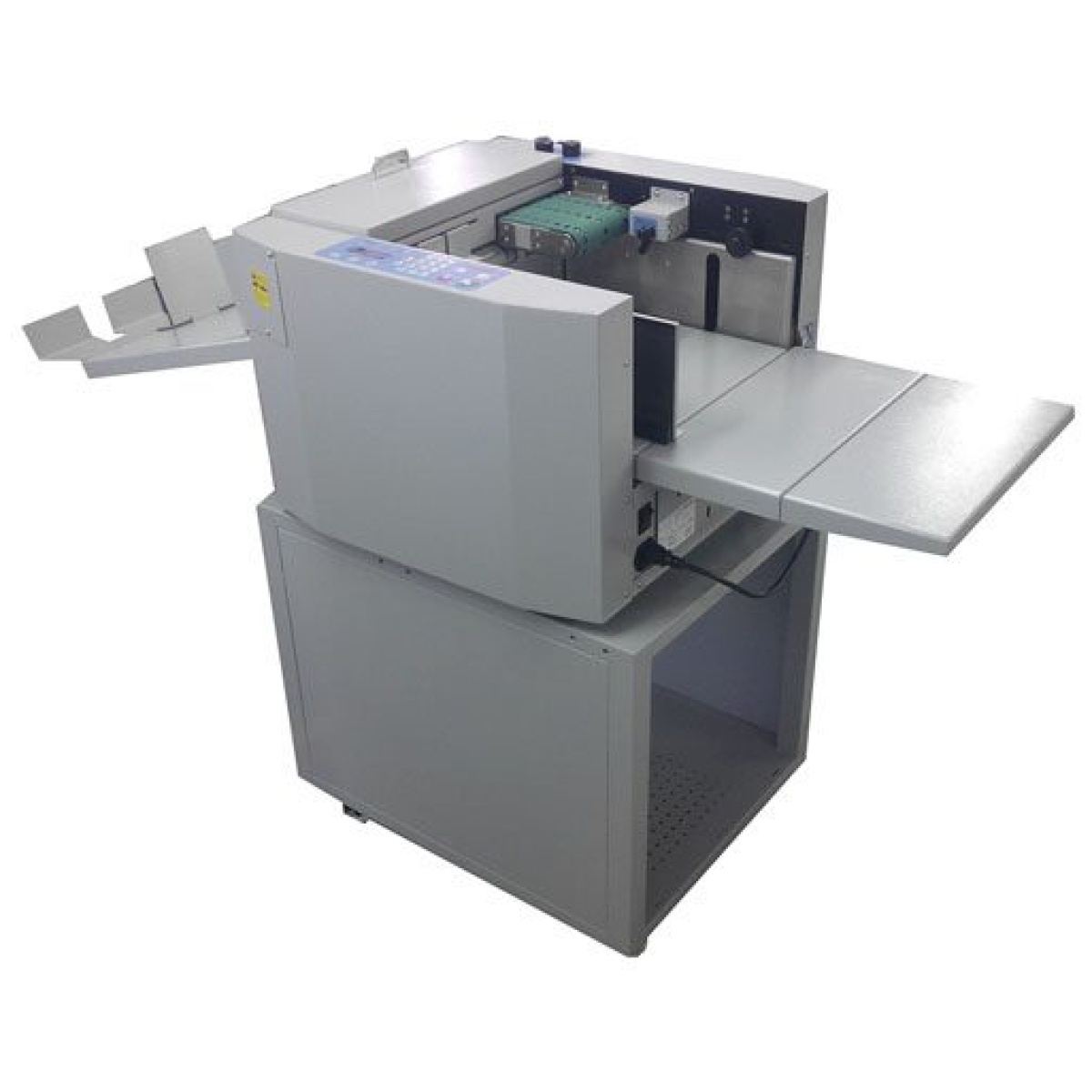

Swift Speed Fold modular creasing and folding system

Swift Speed Fold is much more than a creasing and folding machine - it is a fully automated, modular finishing center designed to meet the highest demands of digital and offset printing. The system consists of two independent but fully integrated units: an advanced creasing-perforating machine and a professional knife folding machine. With this design, the machine offers unparalleled versatility, performing in a single pass creasing, folding, perforation (including segmented "box perf"), notching and slitting. Built around a vacuum top-loader and capable of processing weights up to 400 gsm, Swift Speed Fold is a complete solution for producing high-quality advertising materials, covers and coupons.

Key features and benefits

🏗️ Modular design - grows with your business

The Swift Speed Fold system consists of two main modules that can work together or separately. You can start with the creasing machine alone, and in the future expand the line with a folding module. Both machines have their own touch screens that automatically synchronize when connected, giving you full control over the entire process from one place.

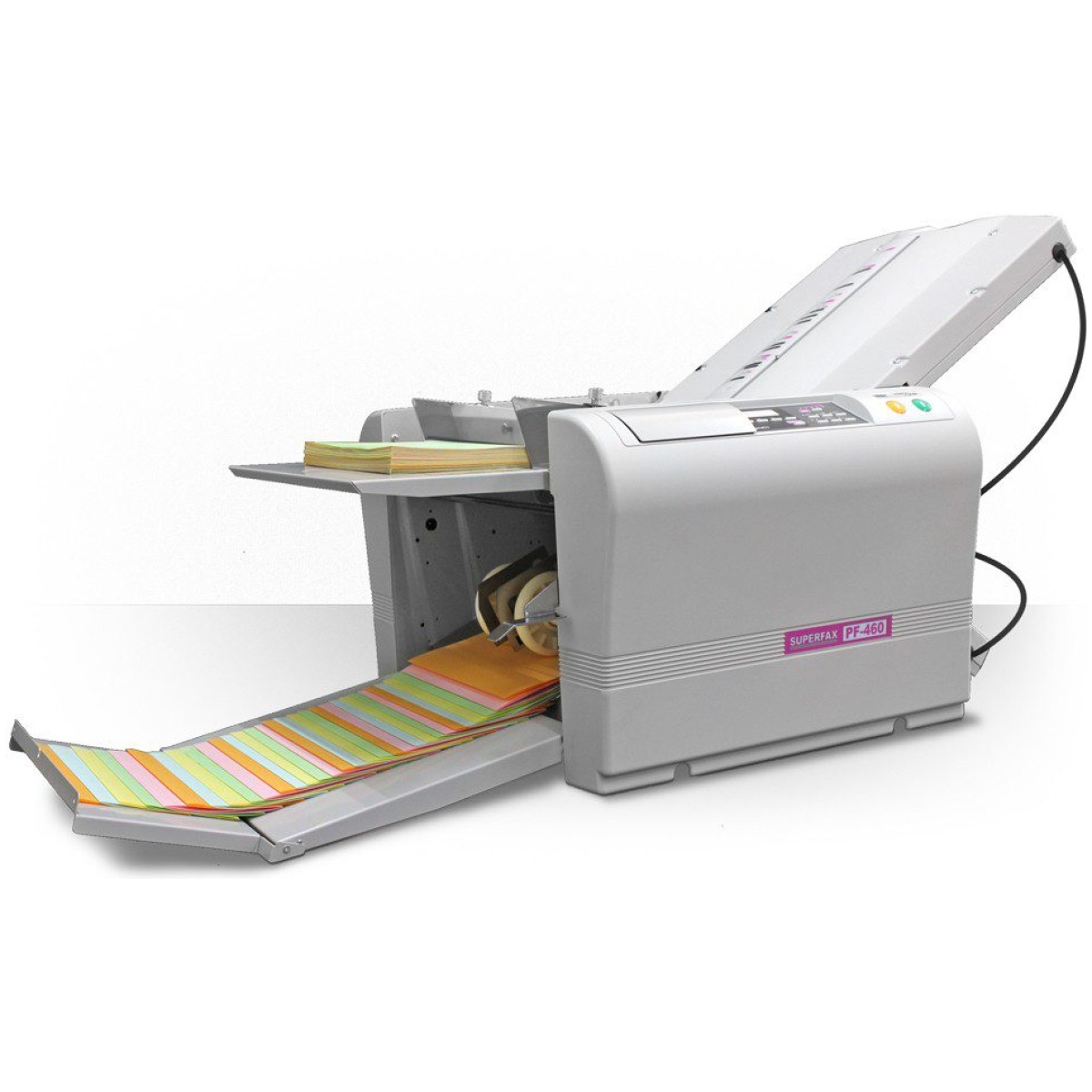

💨 Professional vacuum feeder (Top Suction)

The 100mm high stack is handled by a fully automated vacuum feeder. It gently transports each sheet, eliminating the risk of scratches and marks, which is crucial when working with delicate digital prints, coated or laminated papers. Optional feeders are also available to handle very small formats.

🛠️ Finishing versatility in a single pass

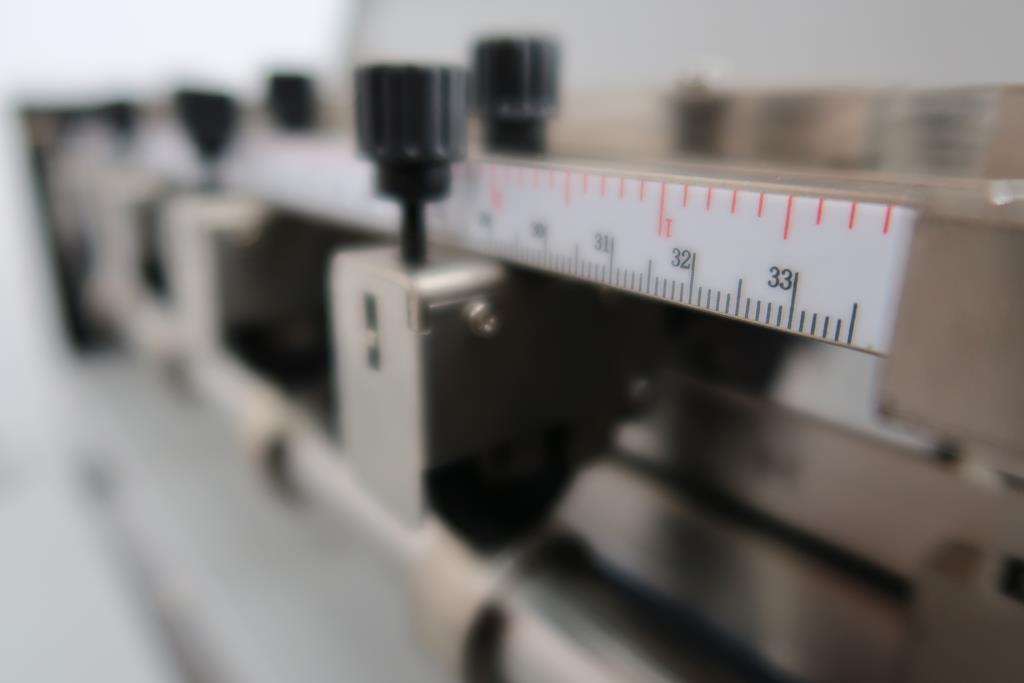

With its "slide-in" interchangeable tool system, the machine can perform multiple operations: creasing (4 different widths), cross and longitudinal perforation (Also segmented "T" or "box" type for skidding), scoring and slitting. All this in one fully automated workflow.

🔪 Knife folding system for thick papers

Unlike standard cassette folders, the Swift Speed Fold uses a professional knife folding system. It is the only technology that guarantees perfect, sharp folding without toner cracking or scratching, even on papers up to 400 gsm. A tape transport table ensures perfect alignment of the sheet just before the folding process.

🤖 Intelligent control and advanced features

Operation is carried out by means of 7-inch touchscreen. The system automatically measures the length of the paper, allows a visual preview of the programmed job, and offers advanced modes such as "Book Cover". for covers with wings or "Progressive" For progressive creasing, which makes it easier to open thicker publications.

Wide production capacity

- Advertising leaflets and brochures On thick, coated papers.

- Invitations and greeting cards With a perfect bend.

- Book covers With wings (in creasing mode).

- Coupons, tickets and vouchers With perforations for tearing off.

- Restaurant menus and price lists requiring multiple breakage.

- Sheets with cut labels (kiss-cutting).

Detailed technical specifications

| Maximum speed | Up to 6,000 sheets/hour (A4, folded in half) |

| Paper weight (folding) | Up to 400 g/m² (1 break) Up to 350 g/m² (2 bows) |

| Sheet format | Min: 140 x 160 mm Max: 330 x 650 mm |

| Feeder capacity | 100 mm |

| Accuracy | +/- 0.2 mm |

| Folding method | Knife folding |

| Types of breaks | 7 predefined types + custom settings |

| Max. creases / perforations per sheet | 32 (in creasing/perforation only mode) |

| Control | 7-inch touchscreen (separate for each module) |

| Creasing strips | Standard: 1.0 mm Options: 0.4, 0.6, 1.2, 1.4 mm |

| Optional tools | Cross-perforation strips (various TPI), longitudinal perforator (also partial), slitting knife, kiss-cutter, creasing machine (scorer). |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.co.uk, we know that purchasing such an advanced system is a strategic decision. That is why we provide full technical support at every stage - From needs analysis and professional configuration, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables (creasing strips, knives) and spare parts.