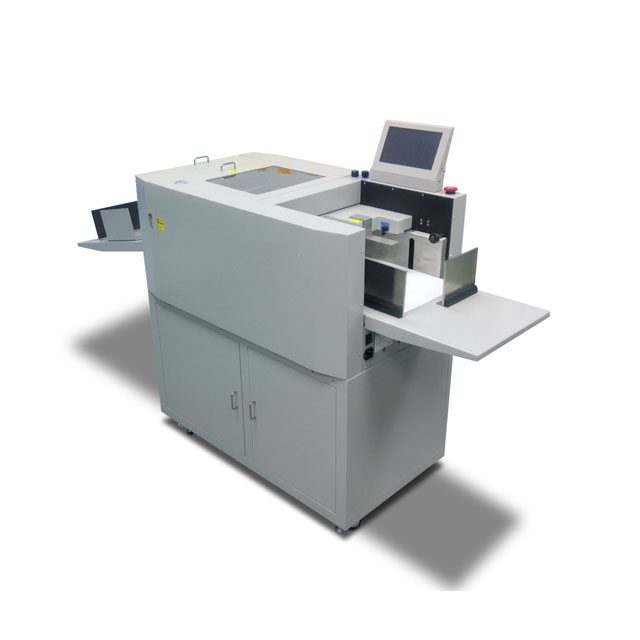

Compact bookbinding machine SCC Lite and SCC Plus

Introducing a series of bookbinding harvesters SCC - A revolutionary all-in-one solution that automates key finishing processes in your print shop. Forget about rearranging jobs between the guillotine, creasing machine and perforator. SCC performs slitting, cross-cutting, creasing or perforation in one pass, directly from an intuitive touch panel. Designed to eliminate the bottleneck in the bindery and keep pace with modern digital presses, the SCC combine drastically reduces turnaround time, minimizes the risk of errors and saves valuable production space.

Key features and benefits

⚙️ All in one pass: cutting, creasing and perforating

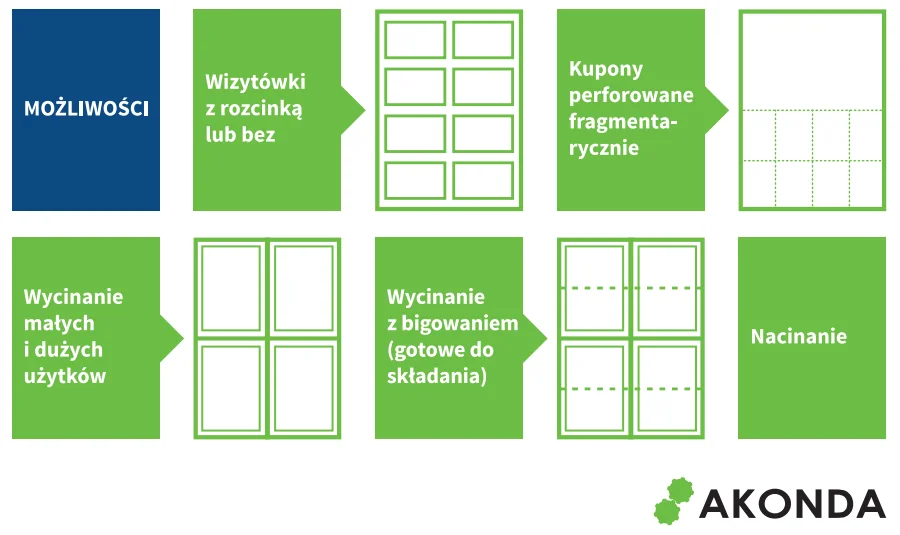

SCC is a true multifunctional shearer. In one cycle, the machine can make up to 32 cross cuts (guillotine), up to 6 rip cuts (slitting discs), up to 32 big or cross perforations. It replaces several separate machines, saving time, space and labor costs.

🤖 Full automation and elimination of errors

The machine is designed to minimize operator intervention. Automatically compensates for image shifts on the printout (in the X and Y axes), a ultrasonic double-take sensor eliminates material waste. The whole thing is managed from a large 9-inch touchscreen.

💨 Professional vacuum feeder (Top Suction)

The high-capacity stacking feeder (100 mm) uses vacuum top-loading technology. This guarantees reliable and gentle feeding of a wide range of media - from 110 to 400 gsm - including coated, laminated and textured papers, without the risk of leaving marks.

🔗 Expanded options and modular design

Customize the machine to suit your needs. Available options include longitudinal (including segmented) perforation discs, additional creasing bars of different widths, notching (kiss-cutting) discs, and a long feed table that allows you to work with sheets up to 1,200 mm long.

Versatile capabilities in one device

SCC Lite vs SCC Plus - choose the version for you

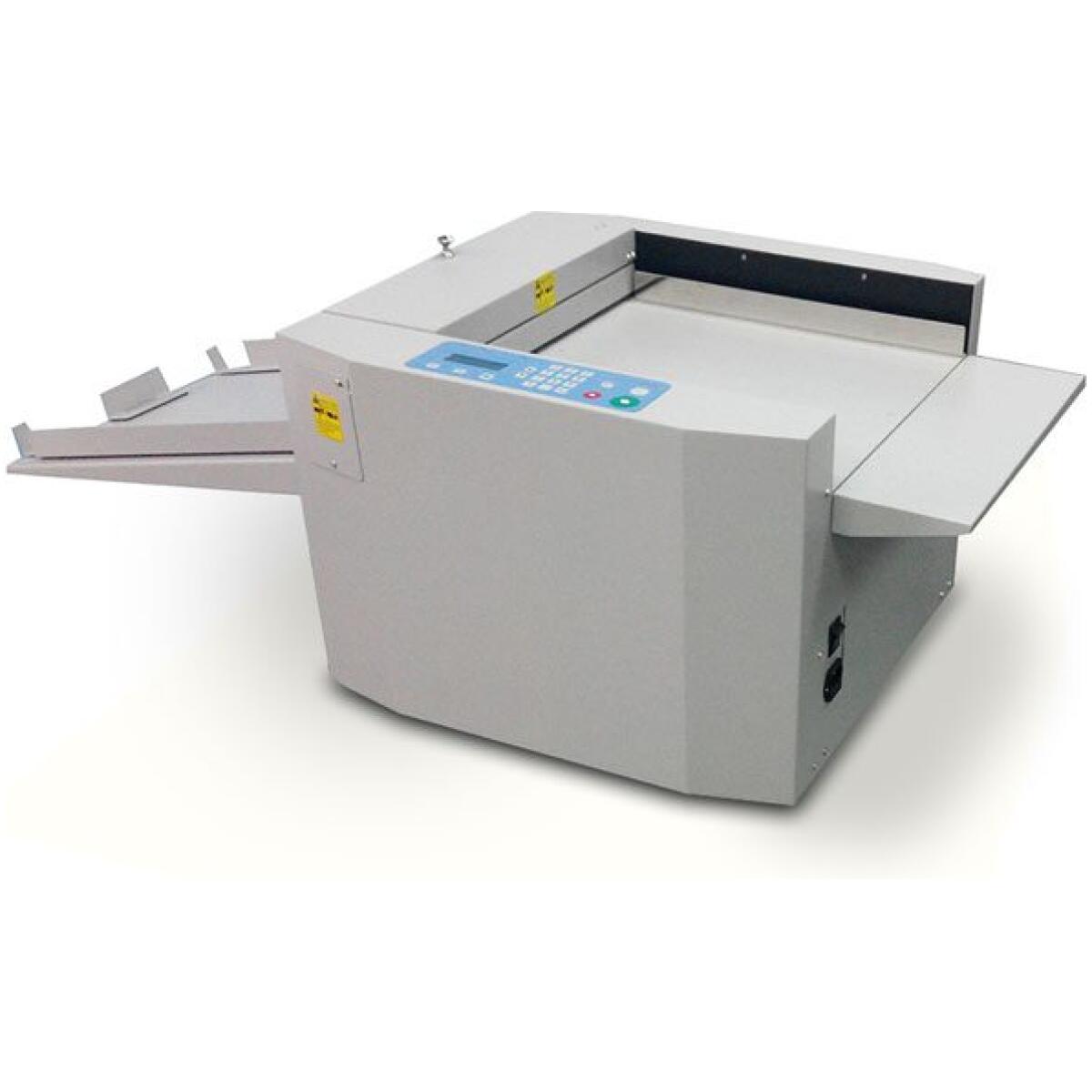

SCC Lite

The most economical, multifunctional bookbinding machine on the market. It offers a full range of mechanical cutting, creasing and perforation capabilities. It is an ideal choice for companies that want to automate finishing, drastically speed up production and become independent of several machines and operators.

SCC Plus

The enhanced version, designed for maximum automation and fully digital workflows. In addition to all the features of the Lite model, the Plus version has:

- Barcode reader: for automatically loading orders and retooling the machine without operator involvement.

- PC communication: enabling central job management and advanced imposition with Trimposer software

- Extended feeder: With additional systems to support the separation of difficult materials.

See the SCC combine in action

Detailed technical specifications

| General parameters | |

|---|---|

| Range of sheet format | Min: 210 x 210 mm Max: 650 x 330 mm |

| Range of weights | 110 - 400 g/m² (0.1 - 0.4 mm) |

| Output use format | Min: 50 x 48 mm |

| Feeder | |

| Type of administration | Top Suction. |

| Maximum stack height | 100 mm |

| Double-take sensor | Ultrasonic (standard) |

| Finishing modules | |

| Cross-cutting (guillotine) | Up to 32 cuts in a single pass |

| Slitting (discs) | 6 knives as standard (automatically adjustable) |

| Cross creasing | Up to 32 large in one pass; depth adjustment |

| Cross perforation | Up to 32 perforations in one pass (12/24/56 TPI strips as an option) |

| Additional options | Disc perforation (continuous/segmented), creasing discs, notching discs |

| Software and control | |

| Display | 9-inch color touchscreen |

| Memory of works | 64 programs |

| Image compensation | Yes, in the X and Y axes |

| Barcode reader | Standard in SCC Plus version |

Partnership with Akonda.pl is a guarantee of peace of mind

At Akonda.co.uk, we know that purchasing such an advanced system is a strategic decision. That is why we provide full technical support at every stage - From needs analysis and professional configuration, to delivery, to implementation and service.

- Professional service Warranty and post-warranty service throughout Poland.

- Delivery, installation and training operators at your facility as standard.

- Permanent access to consumables (strips, knives, discs) and spare parts.