The potential of digital printing combined with the ability to cut and crease cardboard or paperboard for packaging, without the need for die-cutting production, is literally unlimited prospects while maintaining a reasonable unit cost even for very low print runs.

Akonda is making sure to take full advantage of the capabilities of its own printing machines by expanding its fleet with the Digital Box Factory series. It's a whole new outlook for conquering such a fast-growing packaging market.

- The importance and role of packaging is changing from advertising on the shelf in the store, to secure packaging that often aligns with the store's visual identity and supports the designed vision of the brand when selling online. In addition, practical considerations are also gaining importance, where packaging is designed for easy, often manual folding and packaging, safe shipping and eventual return. All of this while supporting environmental concerns, through the lack of storage and no risk of underutilization of produced packaging, which fits perfectly with the fundamental concept of digital on-demand printing, says Dominik Szulim, co-owner of Akonda.

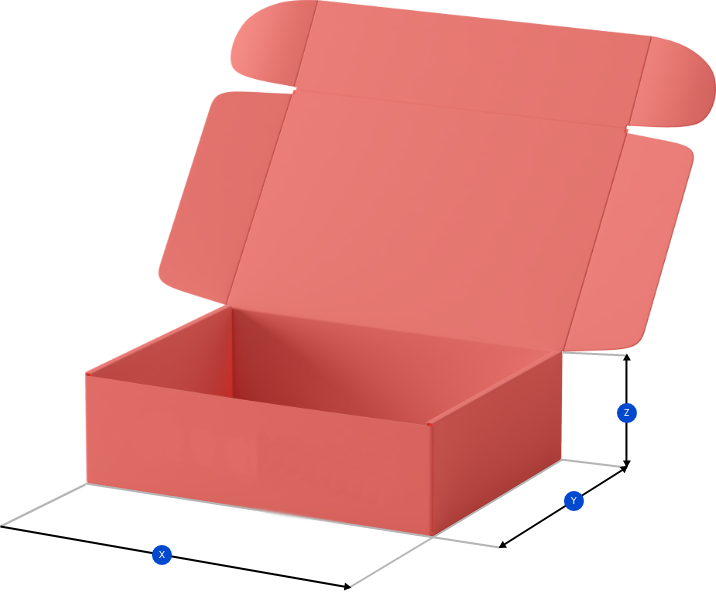

The world's largest consulting firms are forecasting high growth in the packaging sector with the support of just digital printing. Print shop owners have been quick to take notice of these new opportunities, not only noticing the proposed solutions, but also appreciating them. That's because the software that Akonda is providing for the Digital Box Factory project is compatible with the 169-model boxes of the largest organizations in the packaging industry - ECMA for cardboard packaging and FEFCO for paperboard packaging. Such solutions offer the possibility to produce relatively small, but more frequently changing series of products placed on the market in a much shorter time, as a demand generation tool. The software allows you to select a box model (FEFCO/ECMA-compliant templates) and adjust the size to suit your needs. The output file is generated with cutting and creasing lines and is compatible with the cutting plotter software.

While top quality printing is crucial in the process, the capabilities of the Qtopic 380 foiling machines available from Akonda will further enhance the quality of the product. This is an excellent solution for foiling digital printing, allowing PP foiling - gloss, matte, soft touch, which is extremely important when protecting surfaces from physical hazards or atmospheric factors. Thanks to the technology available in GMP Qtopic 380, it is possible to reproduce the enhancements known from high-volume, highly-processed packaging such as - gilding, silvering, hologram application. These can create a stunning visual effect or protect the packaging from counterfeiting. Importantly - all this without matrix or preparation costs, from one piece, while maintaining a reasonable level of pricing.

Next up is the innovative iEcho cutting and beading plotter, equipped with a suction feeder that transports the sheet to the felt belt. The cutting can be done with a trailing or oscillating knife for thicker materials, making the iEcho PK-series cutting and beading plotter suitable for the graphic arts, advertising, packaging industries, for low/medium runs in a convenient and truly efficient way. The iEcho PK allows cutting, notching, creasing, perforating - all within one machine. The machine is equipped with an automatic sheet feeder, a built-in CCD camera for accurate image positioning on paper. The systems used ensure accurate work, a unique, high-quality product to be realized in a short time and in a limited space. Pneumatic creasing system with a pressure of 4000 g allows easy folding of cardboard/paper after processing. The maximum weight of creased cardboard/paper is up to 400g/m2.

iEcho is a global provider of cutting and creasing plotters for a variety of industries, with innovation embedded in the organization's DNA, which provides the ability to process materials such as PVC foam, stickers, foams, reflective films, cardboard, paper, corrugated board, solid board, polycarbonate, magnetic film or others. The capabilities of the software provided by Akonda with iEcho PK / PK PLUS include automatic data matching for cutting, creasing, perforating and other processes without manual setting, a cutting mark plugin available for Corel Draw and Adobe Illustrator, 6 different methods for setting cutting marks, automatic merging of segments in a grid file to increase productivity, or automatic error diagnosis by remote access to machine parameters.

- The entire Digital Box Factory line gives printers tremendous opportunities for growth. It's very encouraging to have a part in supporting customers who will consequently realize the needs of their customers. The guarantee of the highest quality and the possibility of realizing a new type of production is an assurance of success for the coming years," concludes Dominik Szulim.

See more at: