Choosing the right cutting plotter is a strategic decision that can significantly affect the profitability and competitiveness of a digital printer. Modern cutting plotters increase productivity by 300% while reducing labor costs by 75%, making them a key component in automating production processes. The market for cutting plotters in Europe is growing at 5.8% per year, driven by the growth of e-commerce, demand for personalization and integration with digital printing processes.

Printing companies of all sizes - from micro-enterprises to large production facilities - are discovering the potential of cutting plotters as a tool to increase margins and open up new business opportunities. The key to success is choosing the right solution to fit your business and growth plans.

Panorama of cutting plotter technology

Today's market offers a variety of cutting technologies, each with its own applications and benefits. Roller plotters with drag knives dominate the production of plotter film stickers, offering precision of 0.1mm at speeds of up to 1200mm/sec.

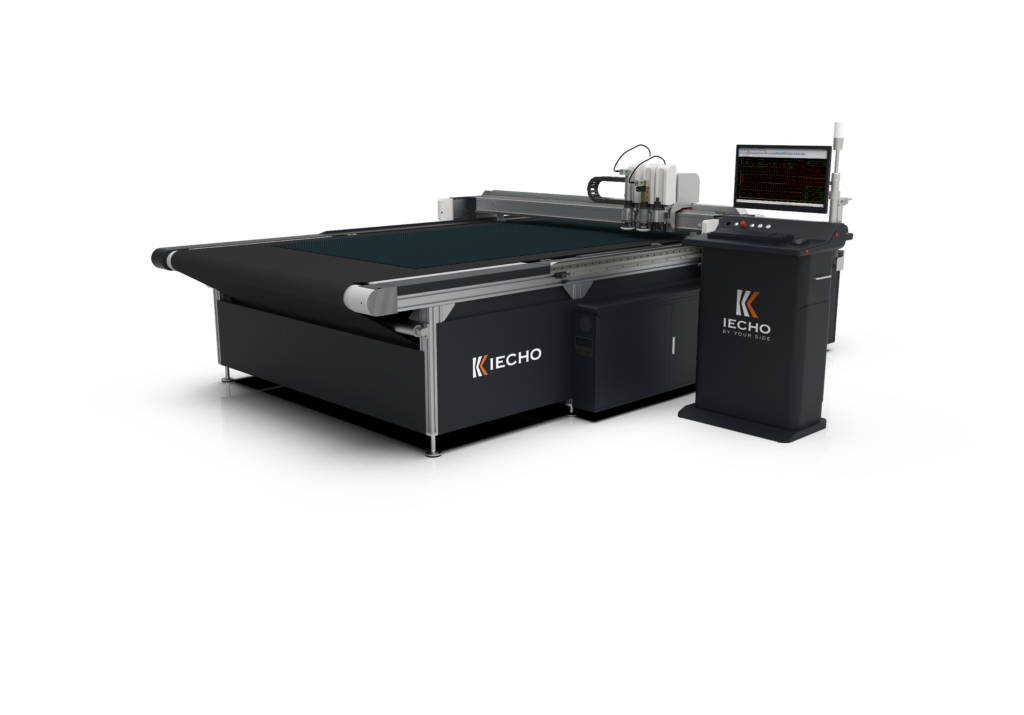

Table plotters with a sheet feeder are revolutionizing the processing of digital prints. They make it possible to cut (slit) self-adhesive papers, chalky papers, cardboard with a thickness of several millimeters. The latest systems combine various cutting technologies - from trailing knives, to active, oscillating and even milling cutters, and creasing - in a single machine.

Industrial-grade CNC systems, such as the TK4S series, offer a modular design that allows customization of the work area from 1.5×1.6m to an impressive 3.2×5.5m. These advanced solutions handle materials up to 110mm thick and are equipped with automatic tool changing systems.

Applications in modern printing plants

Cutting plotters are opening up access to lucrative market segments for printers. Packaging production is the area with the highest profitability, where margins reach tens of percent using automatic cutting systems. Plotters make it possible to create box prototypes according to the standards of FEFCO and ECMA, among others, eliminating the need for costly classic die-cutters.

The advertising sector offers permanent orders for vehicle wraps, signs and promotional materials. Plotters with positioning marker systems ensure precise print and cut alignment, crucial for complex projects. Automatic detection of registration tags reduces job preparation time from hours to minutes.

The textile and apparel industry uses plotters to produce applications, patterns and cutting templates. Modern systems handle fabrics from the finest to technical composites, with cutting force regulated by software. Integration with CAD systems allows direct transfer of designs from design programs.

Automation drives efficiency

Modern plotters are automation centers that connect to production management systems. Barcode-based workflow eliminates operator errors and speeds up order processing o 75%. Automatic positioning systems recognize printed marks and automatically adjust cutting parameters.

Integration with RIPs allows jobs to be sent directly from the printing system to cutting. Hotfolders allow automatic processing of jobs dropped into specific network folders.

Advanced nesting systems optimize the placement of parts on the sheet, reducing material waste by as much as 30%.

Which iecho plotters have these features? All of them right? You can make a carousel/list of products that automate this pulled from woo

Return on investment convincing numbers

ROI analysis of cutting plotters shows attractive financial prospects. Small printers see return on investment in 6-18 months, mainly due to the ability to take on new types of jobs and automate processes. Medium-sized companies with professional-grade plotters achieve a turnaround in 12-24 months, taking advantage of full automation capabilities.

Operating costs remain predictable - knife replacement costs 50-200 PLN, and one knife lasts for an average of 50 hours of work, depending on the material.

iEcho solutions for any scale of business

The PK series represents a comprehensive approach to cutting automation for a variety of business needs. Model PK0604 is the ideal solution for small printers - the 400×600mm format, built-in compressor and automatic vacuum system take up less than 2m² of space. The automatic positioning system with CCD camera and QR code scanning ensure professional quality in a compact size.

The PK0705 extends capabilities to B2 format (530×750mm), offering the optimal combination of versatility and productivity for medium-sized businesses. As with the PK0604, an automatic sheet-loading system and pneumatic creasing with 4kg pressure allow processing of materials up to 400g/m². For large operations PK1209 offers a cutting area of 1200×900mm with five modules: trailing knife, active knife, kiss-cut, oscillating knife and creasing wheel. Three vacuum suction zones and programmable cutting depth control ensure versatility while maintaining industrial precision.

The BK4 and TK4S high performance systems represent the pinnacle of automation technology. The BK4 achieves 1800mm/sec with 30% increased frame stiffness and reduced noise levels to 65dB. The TK4S in a modular configuration allows scaling from 1.5×1.6m to 3.2×5.5m with a dual portal system for maximum productivity.

A selection strategy for the future

The decision to choose a plotter should take into account not only current needs, but also business development plans. Investing in a system with capabilities that exceed current requirements provides room for growth without replacing hardware. The modular design of modern plotters allows for gradual expansion of functionality as the company grows.

It is crucial to choose a partner that offers not only equipment, but complete technical support and training. Akonda, with nearly 200 cutting plotter installations and a team of five service technicians, provides comprehensive support from demonstration to implementation to service. The showroom in Piaseczno allows hands-on testing of equipment before purchase, which minimizes the risk of a wrong choice.

The future of cutting plotters is far-reaching integration with Industry 4.0 systems, artificial intelligence in production optimization and full workflow automation. Companies investing in advanced solutions today will have a competitive advantage in the coming years when automation becomes the market standard.