Paper creasing machine - what it is and to What does it serve in the printing industry?

A creasing machine is a device that plays a key role in the printing and office industry. It is used to carry out the creasing process, i.e. the folding of paper. In this article we will take a closer look at it and discuss the different types of creasing machines available on the market.

What is creasing?

Creasing is a bookbinding process that involves making a groove in paper. According to Polish standard PN-82, creasing is defined as "making permanent indentations in thick bookbinding materials to facilitate their bending along an intended straight line."

This process is essential when working with high grammage papers, usually from 150 gsm upwards. More and more printing articles, such as flyers, invitations, brochures and book covers, are made on papers with weights as high as 240-350 g/m². With such thick materials, folding without prior creasing can lead to serious problems.

The problem with thick papers

With high paper weights, a serious issue is the folding of such prints. Traditional folding methods have their limitations:

- Cassette folding machines cannot fold such thick papers.

- Stand-alone knife folders do not achieve the precision necessary for folding this type of work.

The only possible way is to fold after creasing the paper.

How does the creasing machine work?

A creasing machine is a device that is used to make precise folds on paper or cardboard. Creasing is the process of making a groove in paper. The imprinting of the groove changes the structure of the paper - the paper fibers are permanently bent, making them weaker and more susceptible to folding.

Two main methods of creasing can be distinguished:

- Roll/roll creasing: Consists of point pressing the creasing roll or disc against the paper.

- Slat creasing: It is based on the simultaneous imprinting of the creasing strip over the entire width of the fold to be made.

Regardless of the method of paper creasing, the effect is similar - paper with a permanently imprinted groove is easy to break.

Advantages of creasing

Bigging eliminates a very serious problem commonly referred to as "paper cracking," which is actually cracking of the paper coating or cracking of the ink or toner on the paper coating. The problem of cracking is usually seen with paper weights above 150 gsm. It is especially noticeable with dark colors - then the dark image contrasts with the cracked structure of the white paper.

Creasing methods

There are various methods of obtaining creasing:

- Application punch, followed by die-cutting - a method that can be used for high volumes.

- Using creasing discs, such as on folding machines or cutting plotters.

- Use of manual, semi-automatic and automatic slat creasing machines.

Paper scalloping is also essential in the processes of making covers for soft bindings.

Types of creasing machines

There are many types of paper creasing machines available on the market to suit different needs and scale of production. In our offer you will find a variety of models, from simple manual creasing machines to advanced automatic devices.

Manual creasing machine

Manual creasing machine is the simplest solution, ideal for small offices or home use. It is used for occasional creasing of small quantities of documents.

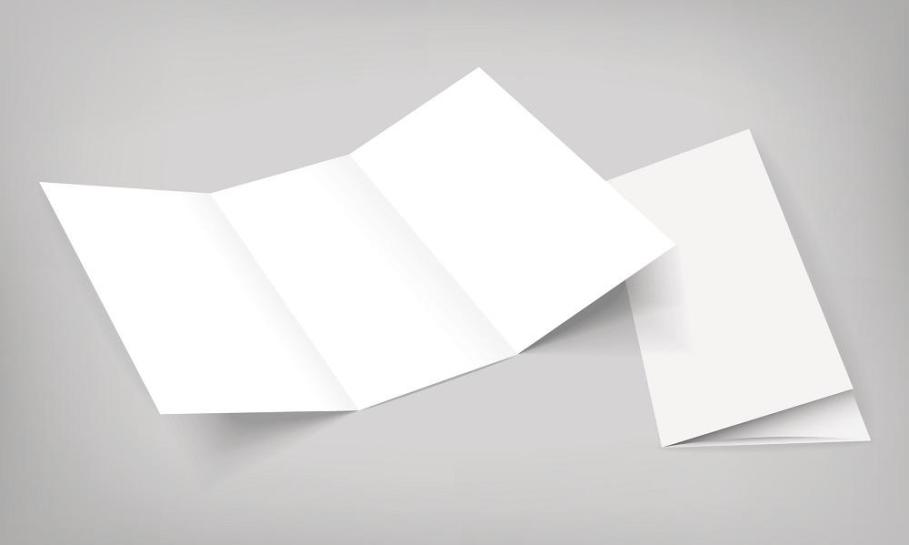

Semi-automatic creasing machine

Semi-automatic creasing machines, such as. Swift 335, are a popular solution in many printing houses. They allow comfortable work with print runs of up to several hundred pieces.

The operation of such a machine consists of:

- Enter creasing parameters (usually the distance from the face of the sheet)

- Performing the test

- Placing successive sheets under the rollers, which automatically carry out the creasing process

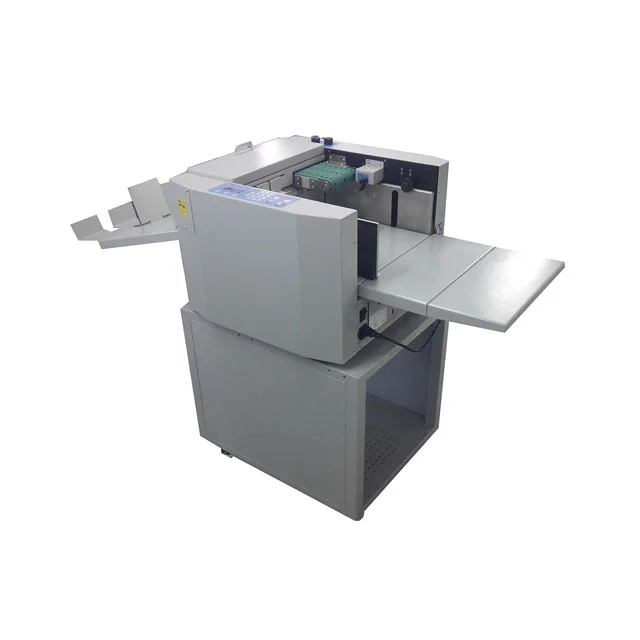

Automatic creasing machine specification

For larger print runs, an automatic creasing machine is ideal. Such a device has a feeder that takes sheets from the stack, which significantly speeds up the process and minimizes the operator's work.

Features of the automatic creasing machine:

- Sheet stack feeder

- Automatic sheet retrieval with a suction belt

- Ability to set creasing parameters on the screen

- The operator's role is limited to watching the process and picking up and adding sheets

Applications of creasing machines in various industries

The creasing machines are used in many fields related to paper production and processing:

Printing industry

In printing houses, creasing machines are an essential piece of equipment for preparing:

- Covers for books and magazines

- Advertising folders

- High-weight leaflets

- Greeting cards

- Invitations

Digital printing

In the digital printing industry, where there is a high variety of work to be done and print runs often do not exceed a few hundred pieces, automatic and semi-automatic slat creasing machines are dedicated.

Bigfoot swift fold from Akondy:

Summary

The creasing machine is an indispensable device in modern printing. It allows professional finishing of printed materials, providing aesthetic and durable folds without the risk of paper or ink cracking.

Current quality criteria do not allow acceptance of broken sheets without regrinding. With a large increase in high-weight work, the current challenge is to increase automation in the folding process.

Regardless of the scale of production - whether in a small office or a large print shop - a properly selected creasing machine can significantly increase the quality and efficiency of work.

We encourage you to familiarize yourself with our offer of creasing machines, where you will find equipment adapted to different needs and scale of production. Our experts will be happy to advise you in choosing the right model that will meet your expectations and contribute to the quality of your printing products.

FAQs - Frequently Asked Questions about Bigfoot.

How does the hand creasing machine work?

The manual creasing machine works on the principle of mechanical pressure, which creates a groove in the paper. The operator manually places a sheet of paper on the machine's platform, then uses a lever or handle to press the creasing bar against the material, creating a precise indentation. This process changes the structure of the paper's fibers, making it easier to later bend the paper exactly along the line created.

What is a hand creasing machine?

A hand creasing machine is a basic bookbinding device used to make precise folds on higher-weight paper. It is the simplest type of creasing machine, designed for working with smaller print runs and occasional use. The device consists of a flat working surface, on which the paper is placed, and a pressure mechanism with a creasing bar.

What are the advantages of using a hand creasing machine?

The main advantages of the hand creasing machine are:

- Low purchase cost compared to automatic models

- Compact size - takes up little space in an office or small print shop

- Ease of use - no specialized training required

- No need to connect to electricity

- Ability to precisely control each creasing

- Ideal for small print runs and custom work

What materials can be creased with a hand creasing machine?

The manual creasing machine allows you to work with a variety of materials, including:

- Paper weight from 150 gsm to 350 gsm

- Cardboard of different thicknesses

- Book covers

- Materials for the production of greeting cards and invitations

- Coated and uncoated papers

- Printed sheets (both offset and digital)

What are the differences between an automatic creasing machine and a manual creasing machine?

The key differences are:

- Capacity: automatic processes up to several thousand sheets per hour, manual requires handling each sheet individually

- Automation: automatic models have a sheet feeder and collection system, manual models require manual operation

- Precision: automatic provides repeatability for large runs, manual gives more control for single sheets

- Costs: automatic are much more expensive to buy and maintain

- Size: automatic take up more space in the studio

What is an automatic creasing machine?

Automatic creasing machine is an advanced bookbinding device equipped with a system of automatic feeding of sheets, creasing unit and receiver of finished works. It has an electronic control panel that allows precise programming of creasing parameters. The machine independently takes sheets from the stack, performs creasing according to the set parameters and puts away the finished sheets, minimizing the operator's participation in the entire process.

When is it worth investing in an automatic creasing machine?

The purchase of an automatic creasing machine is justified when:

- The company regularly processes large volumes (more than several hundred sheets per day)

- Repeatability and precision in large batches is important

- Turnaround time is key

- The company aims to automate production processes

- Company has sufficient production space and budget for investment

What are the disadvantages of a manual creasing machine compared to an automatic one?

The limitations of the hand creasing machine are mainly:

- Low productivity at higher volumes

- Less repeatability with large batches

- Greater operator fatigue with prolonged work

- Greater risk of human error

- Longer lead times for larger orders

What applications does the creasing machine have in printing houses?

In the printing environment, creasing machines are used for:

- Preparing covers for books and brochures

- Production of catalogs, brochures and flyers of high weight

- Making greeting cards and invitations

- Preparation of marketing materials folded into several parts

- Production of folders and binders

- Cardboard packaging creasing

How does the creasing machine assist the printing process?

The creasing machine is an indispensable link in the finishing process of a printing house because:

- Prevents cracking of paint and paper coating on bend lines

- Enables professional finishing of printed materials on thicker substrates

- Enhances the aesthetics of the final product

- Ensures precise and easy folding of materials

- Increases the durability of bends in printing products

What types of creasing machines are used in printing?

Various types of creasing machines are used in the printing industry:

- Slat creasing machines (manual, semi-automatic and automatic)

- Roller/circle creasing machines (often as part of folding machines)

- Bifolders integrated with cutting plotters

- Creasing-perforating machines combining creasing and perforating functions

- Creasing and folding machines enabling creasing and folding in one cycle

Related products:

-

Swift Speed Fold creasing machine

-

Swift Speed automatic creasing machine

See in the show-room -

Swift 333 and Swift 336 manual creasing machine

See in the show-room