Binding what is it? A complete guide to document binding

Binding is a professional technique for binding loose sheets of paper into a cohesive whole, which is the foundation of modern bookbinding. From the Latin "intro" meaning "to bind" and "ligare" meaning "to bind," the term has evolved from a medieval craft to modern manufacturing automation technology. In the digital age, where electronic documents dominate business communications, traditional binding is gaining a new dimension - becoming a tool for building a professional image and effectively organizing company documentation.

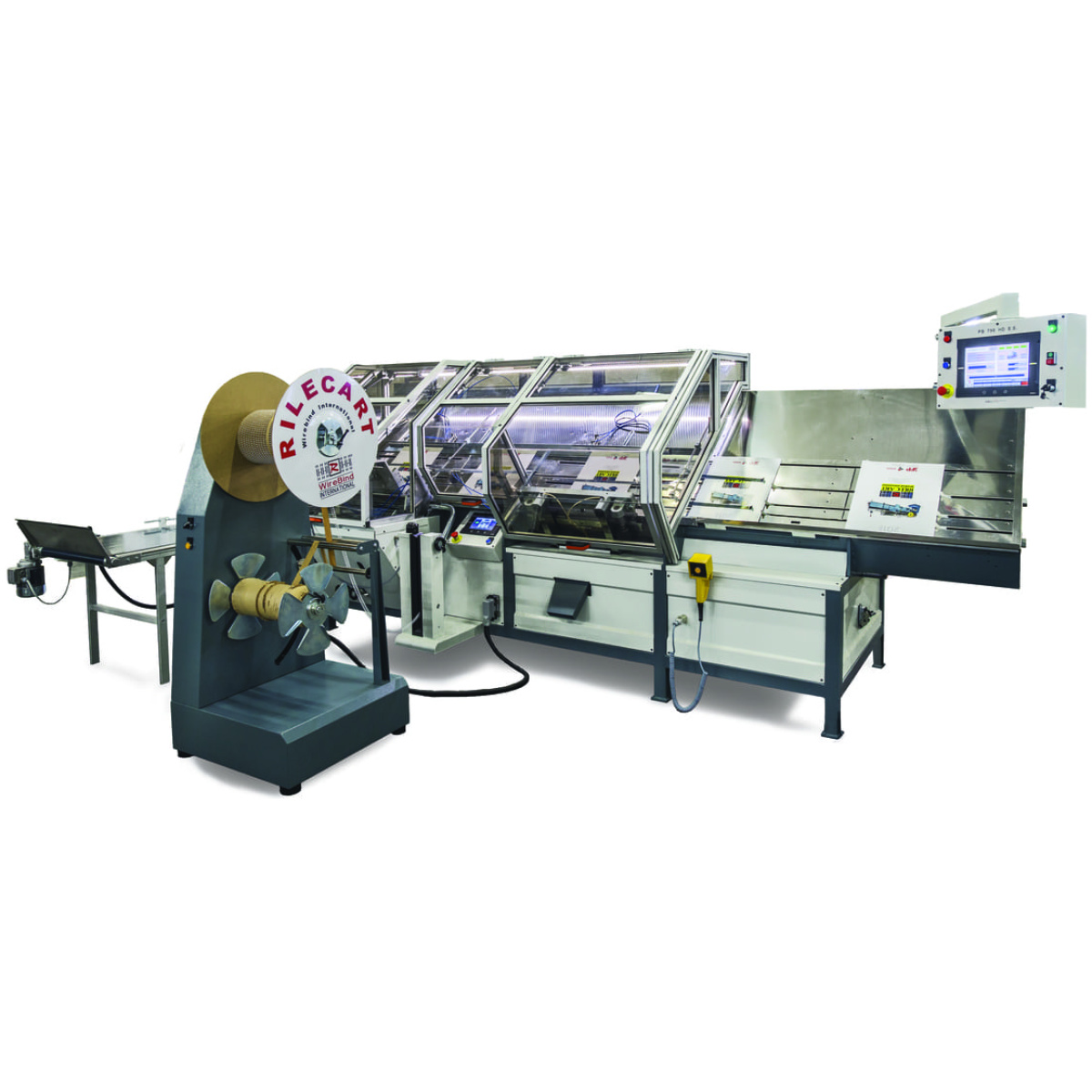

Modern printers and printing companies are discovering that binding is not only a way to organize documents, but above all an investment in automating production processes. Modern spiral binding systems, such as the PB-799 HD ES automatic machine offered by Akonda, can bind up to 2,600 calendars per hour, fundamentally changing the economics of producing promotional materials and technical documentation.

What is bindery and why it is revolutionizing bookbinding

Document binding is a process that involves binding individual sheets of paper together using special tools. Unlike traditional bookbinding methods that require complicated sewing or gluing processes, binding offers speed, flexibility and cost-effective production. The word "binding" in a printing context is derived from the English term "binding," which literally means "binding" or "binding."

A key advantage of binding is its versatility of application. From simple office documents to training materials and presentations to sophisticated product catalogs and wall calendars, any type of documentation can get a professional binding tailored to specific usage requirements. Binders, using either manual or electric mechanisms, are required for the binding process, allowing production to be scaled from single copies to multi-thousand-issue runs.

Modern bindery is also a response to increasing demands for personalization and short production runs. In the era of digital printing, where each copy can be unique, traditional bindery methods are becoming uneconomical. Binding makes it possible to bind even a single document while maintaining production profitability.

Types of bindings - from classics to innovations

The world of binding offers a variety of technologies to suit any type of documentation and scale of production. Plastic comb binding is one of the most widely used types of binding, due to its simplicity and functionality. This system allows the binding of up to 500 sheets, offering the possibility of later modification of the contents - an invaluable advantage for technical documentation or training materials.

Spiral (coil) binding represents another level of functionality. In addition, a huge advantage of spiral binding is the ability to turn the pages 360 degrees, making this method ideal for calendars, notebooks and presentations that require full unfolding. Metal or plastic spirals are available in a wide range of colors, allowing you to match the aesthetics to your brand identity.

Thermobinding Is distinguished by its elegance and simplicity of execution. The sheets should be evenly arranged in the selected cover, and everything should be placed in the binding machine. Later, along the back of the file, you need to spread glue, which will heat up and thus glue everything together. This method, often required for the binding of theses, provides a professional appearance similar to publishing books.

Channel binding offers a compromise between aesthetics and functionality, using special clamping channels. This system is particularly suitable for design documentation and presentation materials, where speed of binding while maintaining an elegant appearance is important.

Automation technology - the key to efficiency

The real revolution in binding came with process automation. The PB-799 HD ES spiral binding machine, Akonda's flagship product, illustrates the scale of this transformation. The machine is specifically designed to handle large formats with the ability to bind two calendars simultaneously, achieving efficiencies unattainable by traditional methods.

The automatic binding process eliminates the most time-consuming production steps. The machine independently punches the entire calendar in one stroke, automatically inserts the hangers and wire, and then transfers everything to the closing section. With a maximum binding format of 800 x 1000 mm and the ability to process calendars up to 4.5 mm thick, this system opens up new production possibilities.

The key technical parameters of spiral binding machines define their use in various market segments. Standard binding diameters from 3/16″ to 3/8″ cover the full spectrum of needs - from thin booklets to voluminous catalogs. The ability to be programmed for continuous binding, two-piece suspension binding or skip-binding mode provides the flexibility to adapt to the specifics of production.

The economics of binding in printing practice

Investment in professional binding systems brings tangible economic benefits. Cost analysis shows that with a production of more than 500 copies per month, a spiral binding machine pays for itself in 12-18 months. Savings result not only from the reduction of labor costs - one operator replaces a team of 3-4 people - but also from the minimization of waste and the possibility of express orders.

Binding also opens up new market segments. Production of corporate calendars, often seasonal and requiring a high degree of flexibility, is becoming profitable even with small print runs. Personalization of each copy, impossible with traditional offset printing methods, combined with digital printing and automatic binding creates a unique value proposition.

The cost of consumables remains predictable and competitive. Wire on spools, used in automatic spirals, costs a fraction of the price of finished spirals, while eliminating the problem of stocking different sizes. Flexibility in material selection - from standard wires to specialized coated spirals - allows costs to be optimized according to project requirements.

Industry applications - from office to industry

The versatility of binding makes it applicable in almost every industry. Education sector uses bindery to produce teaching materials, scripts and theses. The ability to quickly update content while maintaining a professional appearance makes this method indispensable in a dynamic academic environment.

Advertising and marketing industry appreciates binding for its ability to create eye-catching presentations and product catalogs. Spiral-bound portfolios, color swatches or material templates combine functionality with aesthetics, reinforcing the marketing message. Automation of the process allows campaigns requiring thousands of personalized materials.

Industry and construction They focus on the durability and resilience of the bindings. Technical documentation, service manuals or construction plans in spiral binding will survive the harsh conditions of use on the construction site or in the workshop. The ability to fully unfold the document makes it easier to work in the field.

One Handy wrapping machine - a compact solution for the demanding

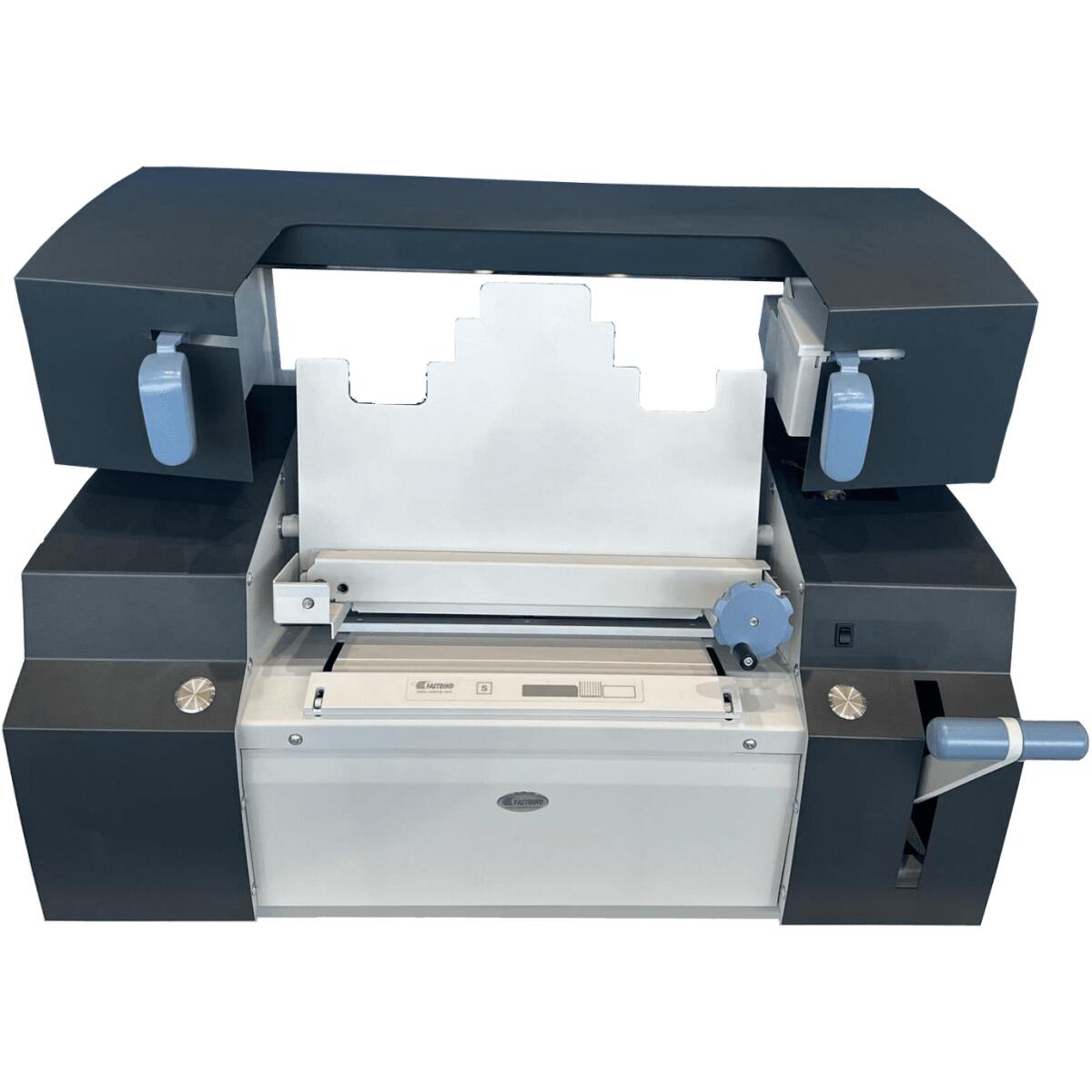

Complementing the spiral binding systems in Akonda's offer is the Fastbind One Handy binder - a device that combines compactness with professional quality book binding. This innovative solution is dedicated to printers and offices looking for versatility in limited working space.

The use of EVA adhesive in the binding process ensures cost-effectiveness while maintaining high binding quality. The heating and binding system allows for orders ranging from single copies to medium print runs, making the device ideal for companies serving a diverse clientele. The intuitive user interface means that operation requires no specialized training.

Fastbind One Handy is used in the production of photo albums, where the quality of binding is crucial for the presentation of photos. Creating promotional materials in small runs becomes cost-effective, opening up new business opportunities for digital printers.

The future of binding - trends and innovations

The development of bindery technology follows Industry 4.0 trends. Integration of systems with production management software allows full automation of the process from order receipt to shipment. Remote assistance modules, standard on modern equipment, minimize downtime and optimize machine utilization.

Ecology is becoming an increasingly important aspect of technology selection. Binding, unlike traditional methods using solvent-based adhesives, offers environmentally friendly solutions. The ability to easily recycle bound documents - by separating the metal spirals from the paper - fits in with the principles of a closed-loop economy.

Personalization and on-demand production are defining the future of the printing market. Binding, with its flexibility and scalability, is ideally suited to meet these challenges. The ability to produce a single, personalized copy while maintaining process economics opens up new business models based on the long tail of sales.

Summary - bindings as a development strategy

Binding has ceased to be just a bookbinding technique, becoming a strategic tool for the development of printing companies. Investment in modern automation systems, such as the spiral binding machines and binders offered by Akonda, is not only an improvement in production efficiency, but above all an opening to new market segments and business models.

The choice of the right binding technology should take into account not only current needs, but also the company's growth plans. The modularity and scalability of modern systems allows for gradual expansion of production capabilities as the business grows. Technical support and training offered by suppliers such as Akonda minimize the risk of investment and accelerate the return on invested capital.

In an era where speed of fulfillment and personalization are becoming key competitive advantages, bindery offers an answer to the challenges of today's printing market. From small offices to large industrial printers, everyone will find a solution to fit their needs and growth ambitions.