Bookbinding machines in a digital printing plant

What are bookbinding machines?

Bindery machines and equipment are essential equipment for any modern digital print shop. In the printing industry, they are used to convert printed sheets into finished products, and the scope of bindery work includes cutting, creasing, folding and stitching materials.

Digital printing - the basis of production

Today's digital printers use three main printing technologies:

Toner printing

- Suppliers: Konica Minolta, Canon, Ricoh, Fuji

- Most popular with commercial printers

- Format usually SRA3 (33x48cm)

- Possibility of banner printing up to 100cm

Inkjet printing

- Manufacturers: Kyocera, RISO, Canon, Konica Minolta

- Technology of the future

- Formats up to B2 (50x70cm)

- Uses water-based or UV inks

HP Indigo Technology

- HP Indigo uses liquid toner

- Superior print quality

- Format up to 750 x 530 mm

From sheet to product

Once a stack of paper sheets is printed, the process of converting them into finished products begins, using specialized bindery machines. The machine operator controls this process, using both manual and automatic machines.

Basic equipment

1. slicers and guillotines

Slicers and guillotines are fundamental devices in any printing house. They are used not only to trim finished prints to format, but also to divide sheets into uses. Modern hydraulic slicers offer:

- Precision cutting of paper stacks of up to 800 sheets

- Programmable cutting sequences

- Safety system with light curtain

- Touchscreen controls

- Ability to save cutting programs

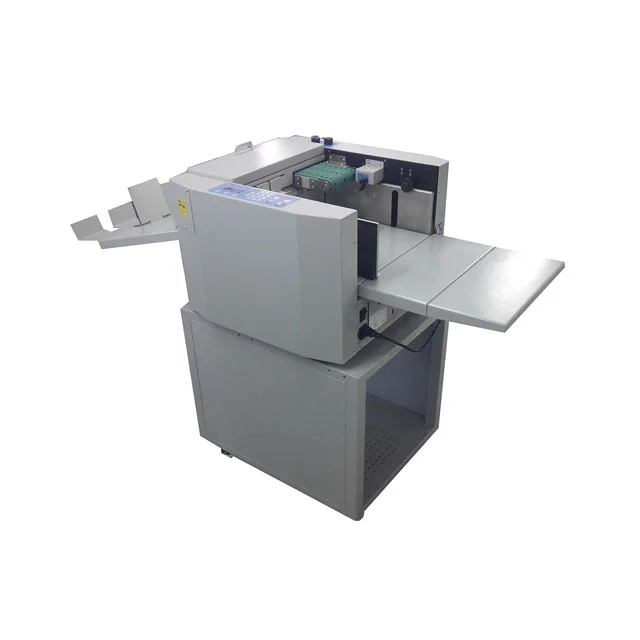

2. creasing and creasing machines

Biggers are indispensable devices in the production of folding materials. Modern creasing and folding machines automate the process by:

- Automatic sheet feeding

- Simultaneous creasing and folding

- Can work with paper up to 400g/m²

- Positioning camera system

- Programmable creasing patterns

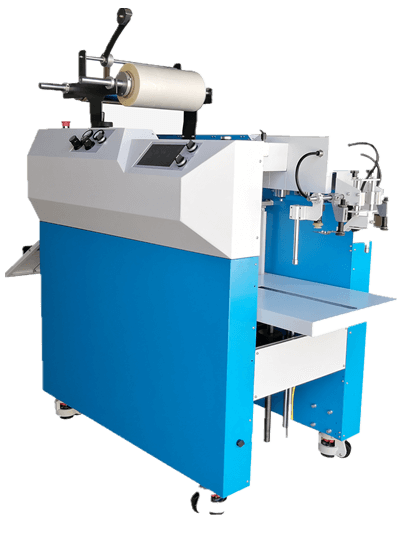

3 Filing machines

Professional film machines enable:

- Single-sided and double-sided foiling

- Work with glossy and matte films

- Foiling with metallized films

- Automatic sheet feeding

- Temperature and speed control

- Ability to work with formats up to B2

4. edge banding machines

Book and catalog production wrappers offer:

- EVA or PUR back bonding

- Back milling

- Automatic cover feeding

- Book thickness control system

- Automatic parameter setting

- Performance up to 200-300 books per hour

Specialized equipment

5. cutting plotters

- Precision cutting of complex shapes

- Production of packaging and labels

- Possibility of cutting and creasing

6. cutters and rollers

- Precision cutting of complex shapes

- Automatic tag recognition

- Perforation and creasing in one pass

- Processing of various materials (paper, cardboard, film)

- Production of labels and packaging

7. bookbinding harvesters

Ausjetech harvesters are advanced multifunctional devices:

- Integrated cutting, creasing and perforation modules

- Automatic sheet feeder

- Positioning camera system

- Ability to perform multiple operations in a single pass

- Programmable machining patterns

- High production efficiency

Selection of bookbinding equipment

Choosing the right equipment depends on:

- Type and input of production

- Format of processed materials

- The required degree of automation

- Available budget

For example:

- A small advertising print shop needs the bare minimum: a slicer, a creasing machine and a foiling machine

- Book printing plant additionally requires: binding machine and gathering line

- Manufacturer of packaging: cutting plotter and creasing machine

Modern bookbinding machines offer a high degree of automation, which translates into increased efficiency and repeatability of production while maintaining the highest quality of workmanship.

Akonda offers professional advice on the selection of bookbinding machines, taking into account the specifics of production, the available budget and the planned development of the printing house.