What is a calender in the printing industry?

A calender is a specialized device used in the paper and printing industry to mechanically finish the surface of paper, cardboard and other flat materials. At Akonda, with more than 15 years of experience in the bookbinding machinery industry, we observe how different finishing technologies affect the quality of the final products delivered to our customers.

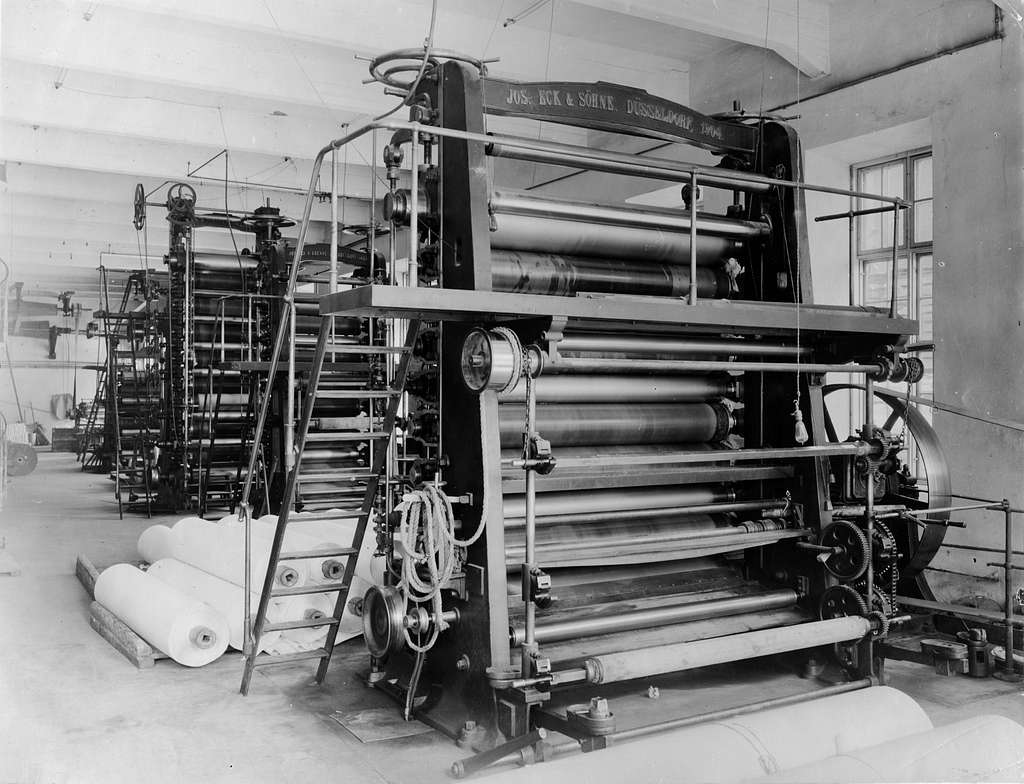

The name "calender" comes from the Greek word "kylindros," meaning roller. The device consists of a series of metal rollers - usually steel or cast iron - that operate under controlled pressure and temperature to impart the desired surface properties to the paper.

The principle of the calender

A calender works on the principle of mechanical pressure exerted by a series of rollers on the material passing through them. The calendering process involves passing paper or cardboard through a system of cylinders, where each successive roller exerts increasing pressure on the material.

As it passes through the calender, the material is left behind:

- Smoothed out - surface irregularities are removed

- Thickened - the structure of the paper becomes more compact

- Compressed - obtains an even thickness

- Glossed - the surface acquires a characteristic shine

The temperature of the rollers can be adjusted depending on the type of material and the desired end result. A higher temperature produces better results, but requires precise control to avoid damaging the material.

Types of calendars in the bookbinding industry

Ordinary calender (machine calender)

The basic type of calender mounted directly in the paper production line. It consists of 2-12 steel rollers arranged vertically. It is mainly used to pre-smooth the paper and give it basic surface properties.

Supercalander

Advanced device equipped with alternating steel and composite rollers. Allows for an exceptionally smooth surface and high gloss. Ideal for producing high-quality papers used in fine art printing.

Soft calender (soft calender)

Equipped with rollers of varying hardness, it allows for gentle finishing of sensitive materials. Often used for coated papers where maintaining the integrity of the coating is crucial.

Multifunction calender

A state-of-the-art solution combining various finishing techniques in a single machine. It can be equipped with humidification, temperature control and variable roller configuration systems.

Calender applications in bookbinding

In bookbinding processes, the calender is widely used, especially in the finishing of materials used in production:

Book covers - Calendering gives covers a professional look, improves ink adhesion and increases scratch resistance. Calendered materials have better color reproduction and print sharpness.

Offset papers - The calendering process improves the printing properties of the paper, reduces its porosity and ensures even ink distribution during printing. This is key to achieving high quality prints.

Laminating materials - Calendered films and synthetic materials show better adhesion during lamination processes, which translates into durability and aesthetics of final products.

Cartons for packaging - Calendering increases the mechanical strength of cardboard and improves its barrier properties, which is particularly important in the production of book packaging and educational materials.

Benefits of using a calender

Improving print quality

Calendered surfaces have better ink adhesion, which results in sharper contours, more intense colors and overall higher print quality. For bookbinding companies, this means the ability to offer premium products.

Increasing durability

The calendering process thickens the structure of the paper, making it more resistant to mechanical damage, scratches and wear. This is especially important for book covers and frequently used materials.

Gloss control

Calender allows precise control of the degree of surface gloss - from matte finish to high gloss. This versatility allows the material to be customized to meet specific project requirements.

Thickness uniformity

Calendering ensures uniform material thickness over the entire surface, which is crucial for automated processes in modern binderies.

Technical parameters and choosing the right calender

Understanding the key technical parameters of the calender is important for bindery companies evaluating the quality of materials supplied:

Working width - should correspond to the formats of the most commonly processed materials. Standard widths are 1000mm, 1600mm, 2000mm and 2800mm.

Number of rollers - determines the degree of finishing. For basic applications 4-6 rollers are enough, for high quality you need 8-12 rollers.

Operating pressure - typically in the range of 200-800 kN/m. Higher pressures allow for better results, but require a stronger design.

Speed of operation - Modern calanders reach speeds of 300-1200 m/min, allowing for efficient production while maintaining quality.

Heating systems - The ability to control the temperature of the rollers in the range of 20-300°C makes it possible to optimize the process for different materials.

Modern innovations in calender technology

Today's calenders are equipped with advanced control systems that automatically adjust operating parameters to the type of material being processed. Vision systems control the quality of the finish in real time, while artificial intelligence algorithms optimize the process for the best results.

Industry 4.0 technologies allow remote monitoring of calender operation, predictive maintenance and integration with production management systems. This translates into higher efficiency and lower operating costs.

Summary

A calender is an important piece of equipment in the paper industry that affects the quality of materials going to the bindery. Understanding calendering processes helps in assessing the quality of raw materials and in making informed decisions about the materials used in production.

At Akonda, thanks to our experience in the bookbinding machinery industry, we understand the importance of high quality materials for final products. Our knowledge of various technologies and processes in the printing industry allows us to better advise customers on the right bookbinding solutions.

An investment in understanding calender technology and its impact on materials is an investment in informed purchasing decisions - in a world of increasing quality demands, companies that understand the entire production path are better prepared to meet the challenges of the bookbinding industry.