Imposition and Bindery: Synergy Key to Printing Efficiency

Imposition and bindery processes are two inseparable elements of modern printing production. Their interaction is fundamental to achieving optimal productivity and the highest quality of finished products. In today's dynamic printing environment, where turnaround time and cost minimization are both important, understanding and exploiting this synergy is critical to the success of any print shop. Ausjetech, as a manufacturer of advanced bookbinding machines, offers comprehensive solutions that fully integrate these two key stages of production, providing users with unparalleled efficiency.

Imposition: the foundation for optimal use of the printing sheet

In the context of printing, imposition refers to the strategic arrangement of multiple copies of the same design or different designs on a single printing sheet. The main goal of this process is to maximize the use of available sheet space, which directly translates into printing more copies in a single run. This approach significantly minimizes paper waste, reduces time operation of printing machines and consequently reduces production costs.

There are many imposition techniques, each with its own specific uses and benefits:

- Sheet Imposition (Sheetwise imposition): This technique involves printing all the front pages of a publication on one side of a sheet and then all the back pages on the other side.4 It is particularly effective for short print runs, brochures, flyers, and projects where the content of the pages does not show significant differences.3 The simplicity of this method makes it easy to understand and execute, making it a good choice for many standard jobs.3

- Step-and-repeat imposition: This technique involves duplicating the same page layout multiple times on a sheet, which is particularly useful for printing business cards, labels or invitations.13 It is an extremely efficient way to mass-produce identical small formats. Imposition software automates this process, saving time and minimizing the risk of errors.13 Users also have the ability to adjust the spacing between duplicated items, which is important for subsequent cutting.13

- Ganged Imposition: This method combines different printed designs on a single sheet, which can significantly reduce production costs by spreading the cost of preparation over multiple jobs.18 While it is cost-effective and reduces paper waste,23 it can come with some challenges, such as slight color variations between designs and limited personalization options.18

The Synergy of Imposition and Bindery: More Than the Sum of the Parts

Efficient printing production is based on close cooperation between the imposition stage and the binding processes - the impositionist. It is the harmonious interaction of these two areas that allows optimal results.

Integrating the imposition and bindery processes brings a number of significant benefits:

- Saving time and materials: Properly planned imposition maximizes the use of the printing sheet, leading to a significant reduction in paper waste.1 In addition, printing multiple pages simultaneously reduces the total printing time required to complete an order.1 Automated workflows resulting from integration eliminate many manual steps and potential delays, further speeding up order fulfillment.30

- Reducing errors: Precise page placement and correct page order, ensured by proper imposition, are critical to the quality of the final product.2 Automation processes imposition and bindery machine settings significantly reduces the risk of human error.31 Specialized software and prepress services play an important role in ensuring accurate imposition, which minimizes potential mistakes.3

- Increased productivity: Streamlined workflows, from pre-press to post-processing, result in faster turnaround times.24 Automation of repetitive tasks allows employees to focus on more complex and demanding activities.31 Systems integration enables better production planning and more efficient use of available resources.26

Today's software plays a key role in facilitating this integration, enabling seamless data exchange between the imposition stage and the bindery machines.31

Challenges of small-format production and Ausjetech's response

The production of small-size materials, such as business cards, invitations and flyers, involves a number of specific difficulties.

Typical challenges include:

- Imposition complexity: Precisely placing many small elements on a single printing sheet can be complicated and time-consuming.17

- Finishing precision: Cutting and creasing small formats requires a high degree of accuracy to avoid inaccuracies and material waste.36

- Toner cracking: With digital printing on thicker papers, toner cracking may occur during folding if proper creasing is not applied.38

- Paper electrification: printing digital can cause electrification of the paper, making it difficult to feed small and lightweight sheets into bindery machines.41

- Drop and cut accuracy: Ensuring that graphics reach the edges and are cleanly trimmed is critical to the professional appearance of small formats.17

- Color Repeatability: It can be a challenge to maintain consistent color on many small items placed on a single sheet.18

Ausjetech offers advanced solutions that effectively address these challenges. Machines such as the 8336BSC and 8330BSC, combined with the Trimposer software, are designed to automate and optimize finishing processes, especially for small formats. The automatic functions and high precision of these machines minimize the risk of errors, prevent toner breakage with interchangeable creasing and perforation dies, and deal with paper electrification problems with advanced sheet feeding systems. Trimposer software simplifies the creation of complex imposition layouts for small formats, and image offset compensation ensures accurate bleeds and cuts. Ausjetech's integrated system guarantees high quality and repeatable small-format production.

Ausjetech's advanced solutions for binderies

Ausjetech SCC series machines: Multifinishers with automatic imposition

Device series Ausjetech's SCC, which includes SCC and SCC Lite models, are multifunctional machines that integrate a guillotine, circular knives and creasing machine in a single housing. A key feature of these machines is automatic imposition - the knives self-position and the sheet is precisely guided to the guillotine. The SCC machines are designed for accurate and efficient cutting, slitting and cross-cutting, as well as creasing in a single pass.36 Integration with Fiery Impose software further automates the finishing process.47 The machines can operate both inline, working directly with the printer, and offline, with any printer of the appropriate height and output speed.42 The automatic setup and multifunctionality of the SCC series significantly increase efficiency and ease of use, which is especially important for printers looking to minimize manual intervention.

Ausjetech 8336BSC and 8330BSC: High Performance and Precision in Finishing

Models Ausjetech 8336BSC and 8330BSC are advanced combiners Bookbinding machines characterized by high efficiency and precision . They provide automation of cutting, creasing and perforating processes, which significantly reduces turnaround time . They feature a high-performance sheet feed system with up to 100mm of vacuum feeder capacity.39Intuitive 9-inch color touchscreen makes it easy to operate and program jobs.37Ultrasonic double-sheet detector prevents feeding errors.36 X- and Y-axis offset compensation system ensures accurate finishing of digitally printed materials.37 Interchangeable creasing and perforation dies eliminate the problem of toner cracking.38The machines also offer partial perforation capability, which is useful for producing materials with tear-off coupons.37 Integration with Trimposer software is accomplished with a barcode reader for a smooth workflow.37 The 8336BSC achieves speeds of up to 25 sheets per minute .

The following table compares the key technical specifications of the 8336BSC and 8330BSC:

| Specification | Ausjetech 8336BSC | Ausjetech 8330BSC |

| Feed size | 210x210mm - 330x900mm (up to 1100mm in software) | 210x210mm - 330x1100mm (optional tray for longer sheets) |

| Receiving size | 50x48mm - 330x1100mm | 50x48mm - 330x1100mm (option for longer sheets) |

| Paper weight | 150-400 g/m² (350-400 g/m² depending on the material) | 110-350 gsm |

| Speed | Up to 25 sheets/min (A4, 2 cuts, 1 big) | Up to 20 sheets/min (A4, 4 cuts, 1 big) |

| Creasing width options | 1.0mm (standard), 0.6/1.2/1.4mm (optional) | 1.0mm (standard), 0.4/0.6/1.2/1.4mm (optional) |

| Slitting capabilities | 6 heads (automatic setting), 4 heads (manual setting - optional) | 6 heads (automatic setting), 4 heads (manual setting - optional) |

| Cross-cutting capabilities | Up to 32 cuts in a single pass | Up to 32 cuts in a single pass |

| Double sheet detection | Ultrasonic | Paper length (ultrasonic - optional) |

| Compensation of the registration mark | X and Y axis | X axis |

| Optional features | Cross perforation, creasing/longitudinal cutting, partial line perforation, automatic card stacker | Cross perforation, creasing/longitudinal cutting, partial line perforation, automatic card stacker, ultrasonic double sheet detection |

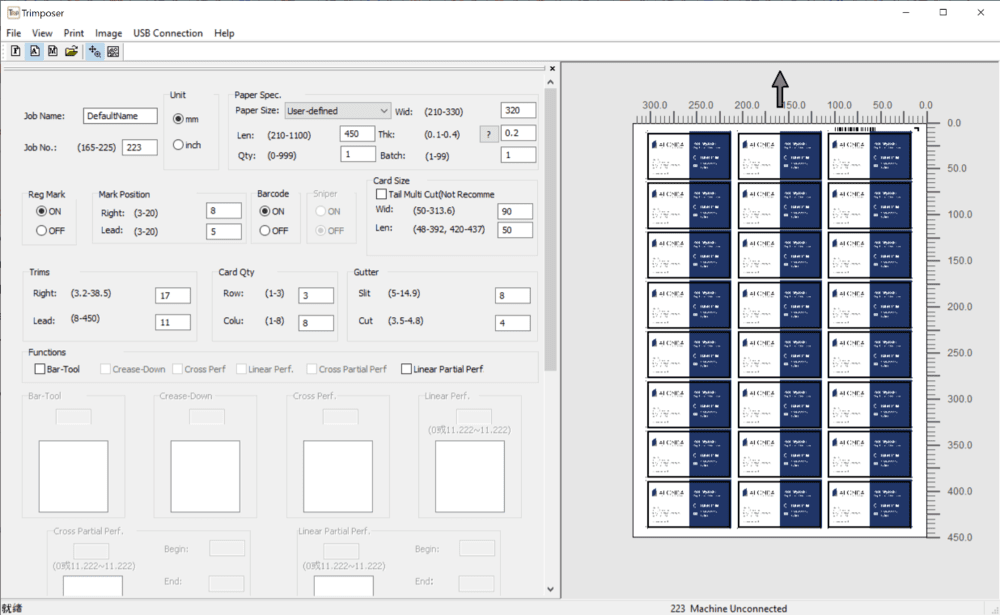

Trimposer Software: Intelligent Imposition Management

Trimposer software was developed by Ausjetech to provide seamless integration with their bindery machines.39 Combines imposition, job management, and error logging functions on a single platform.39 Uses barcode generation and reading technology to link the prepress stage with the finishing process.32 This reduces machine programming time and minimizes the risk of errors. Trimposer enables quick creation of imposition layouts by simply entering paper sizes and target formats.52 Synchronizes job information between the software and the binding machine.52 Enables remote operation of the machine from a PC,52 and generates error logs and production reports for job monitoring.52 The software features intuitive icons for easy handling of complex imposition jobs.52 It is compatible with Fiery Impose templates, further streamlining workflow.32 Users can start and stop bookbinding machine directly from the Trimposer interface, and any error reports from the machine are also displayed in the software.52

Trimposer is specifically designed to create precise imposition layouts tailored to Ausjetech machines.39 It optimizes layouts to minimize waste and maximize productivity, especially for small formats [original article]. Templates take into account the specific requirements of Ausjetech finishers, including margins and bleeds.32 The software handles the complex task of combining multiple designs on a single sheet, which is common in small-format printing with variable data or many different designs.52

User Experiences and Case Studies

Also worth mentioning is the integration with Fiery's EFI workflow, for which there are documented case studies confirming efficiency gains.25 One example is a case study of a number of US companies that shows how integrating Fiery JobFlow with finishing automation streamlined workflows and reduced prepress time by 80%, the case illustrates the benefits of integrated workflows in the finishing process.

The future of imposition and bookbinding processes in printing

The future of the printing industry's imposition and binding processes looks promising, with numerous innovations and trends shaping its direction:

- Increasing automation: Artificial intelligence and machine learning are expected to play an even greater role in optimizing print jobs, predicting maintenance needs and automating workflows.57

- Sustainability: There is a growing demand for green printing practices, including waste reduction and the use of environmentally friendly materials.57

- Personalization and variable data printing: Personalized, customized printed products are becoming increasingly popular.57

- Integrating digital and traditional print: Using technologies such as QR codes and augmented reality (AR) to combine printed materials with digital content.57

- Low-volume and on-demand printing: Demand is growing for smaller print runs and shorter lead times.57

- Smart packaging: Introducing technology into packaging to increase functionality and improve the customer experience.57

- Luxury finishes: Finishes such as foiling, embossing and special coatings are increasingly being used to add value and appeal to printed products.61

Ausjetech's solutions fit perfectly into these future trends, especially in terms of automation, efficiency for short runs, and the ability to handle personalized small-format materials.

Summary: Investing in Efficiency with Ausjetech

Close cooperation between the imposition stage and bindery processes is crucial for achieving high efficiency and quality in print production. Ausjetech's solutions, combined with Trimposer software, provide a comprehensive tool to automate and optimize these processes, especially for the production of small-format materials. By choosing the SCC series machines and the 8336BSC and 8330BSC models together with Trimposer software, printers are investing in increased productivity, reduced costs, improved quality and the ability to meet the growing demand for small-format printing. We encourage you to contact our specialists to learn more about how Ausjetech solutions can contribute to your company's success.