Brochure

Booklet production is one of the basic bookbinding processes, so we offer a range of equipment for different applications:

- C.P. Bourg booklet making systems - high-performance systems for in-line booklet making with a digital printing machine, next to the line (near-line), off-line (off-line). The only equipment on the market allowing full bi-directional integration with the printing machine and full control of the booklet-making process;

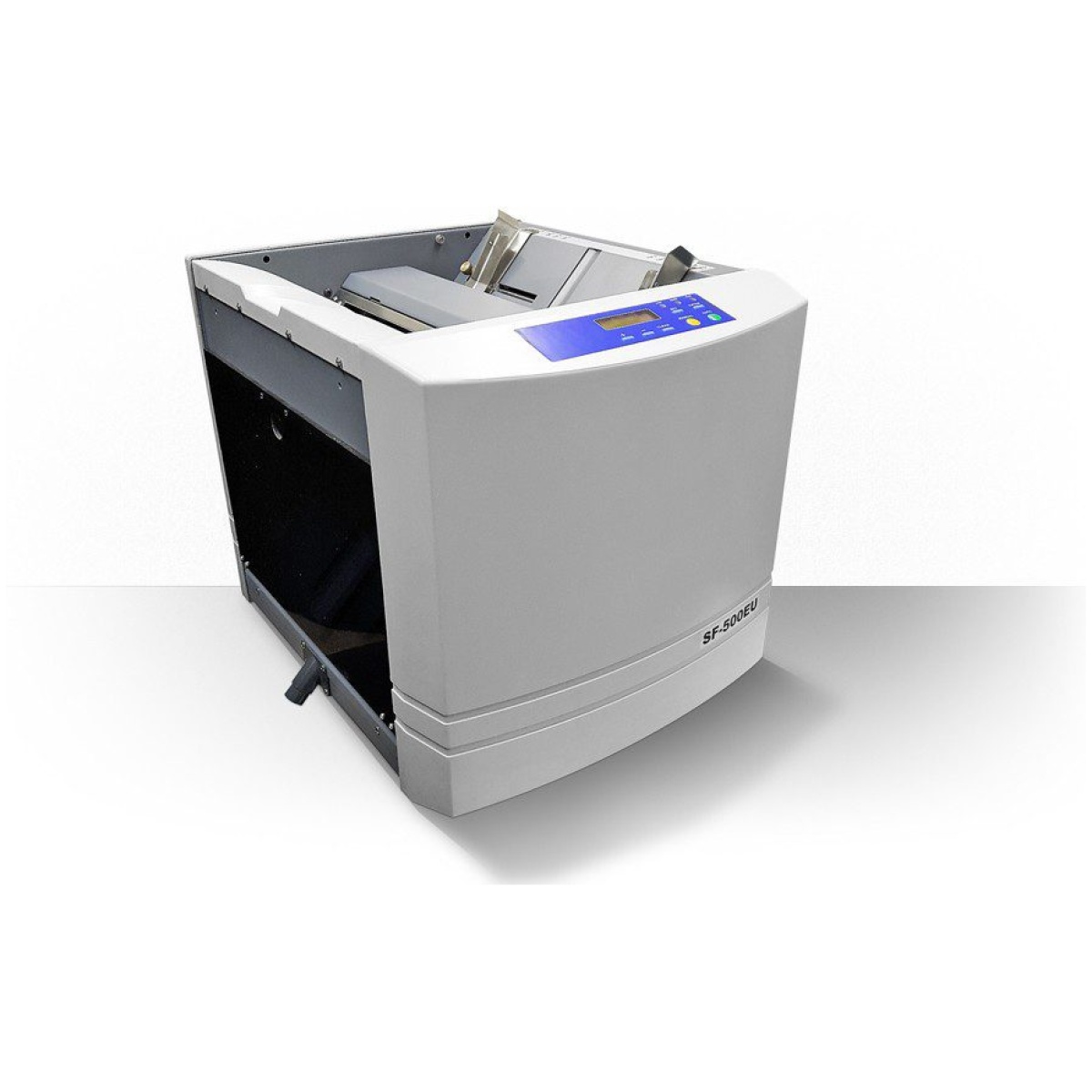

- Stand-alone/offline booklet makers - solutions that allow you to manually place a set in the machine and get a finished booklet. The machine staples and automatically assembles the set.

- Staplers - heavy duty single or double head bookbinding staplers for saddle stitching and block stapling

Brochure making - modern production techniques and technologies

What is broaching and why is it gaining popularity?

Bookleting is an advanced bookbinding process that involves binding sheets of paper together to form a cohesive document through saddle or side stitching. Unlike traditional binding methods, bookleting offers an ideal compromise between quality, aesthetics and production costs. The process eliminates the need for costly spirals or covers, while ensuring the professional appearance of the final product.

Modern booklet making uses advanced machines that automate the entire process - from taking sheets from feeders, creasing covers, wire sewing and final trimming. This makes it possible to achieve products of comparable quality to perfect binding, at much lower unit costs.

Types of broaching techniques

Saddle stitching

The most common technique, in which sheets are folded in half and stapled along the fold line. This method produces booklets in formats ranging from 148.5 x 80 mm to 330 x 240 mm, ideal for product catalogs, manuals or promotional materials.

Side sewing

A technique that involves stapling sheets together from the side, mainly used for thicker publications. Allows production of booklets with formats from 268 x 112 mm to 330 x 247 mm, especially useful for technical manuals or guides.

Booklet making with progressive creasing

An innovative technology in which the crease line is intelligently moved on each successive sheet. As a result, when folded, the booklet forms a perfectly flat, square spine, resembling a glued binding. This solution is particularly valuable when using high weight papers.

Modern brochure systems

Integrated production lines

Today's booklet-making systems are complete production lines enclosed in a single machine. They are equipped with double-feeders with on-the-fly cover creasing, professional sewing heads using steel wire from a spool, and integrated front trimmers with automatic cuttings ejection.

Process automation

Modern booklet makers offer full automation of settings from touch panels. The side and back guides, trimmer cutting position, and folding roller pressure are automatically adjusted, eliminating the need for manual setups and significantly reducing production preparation time.

Quality control systems

Advanced features such as ultrasonic double-take detectors, marker reading systems or manual sheet-loading options provide full control over the production process and eliminate the risk of errors.

Applications of booklet making in various industries

Advertising and marketing industry

Brochure-making is widely used in the production of product catalogs, promotional materials and corporate presentations. The possibility of using enhancement materials, such as matte, glossy or satin films, allows the creation of publications with high visual value.

Education sector

In the education industry, booklet-making is used to produce training materials, scripts and guides. The possibility of using eyelet staples (euro staples) allows the printout to be placed in a binder, which increases the practicality of use.

Catering and hospitality

Professional restaurant menus and price lists made using the booklet technique are characterized by high aesthetics and durability. A perfectly flat spine ensures that publications lie flat and do not get damaged by frequent opening.

Economic benefits of booklet making

Optimization of production costs

Using steel wire from a spool instead of ready-made staples drastically reduces the unit cost of each booklet. This solution is especially important for large print runs, where the savings can be significant.

Production efficiency

Modern booklet making systems allow the preparation of up to 350 bindings per hour, far surpassing the output of traditional manual methods. Full automation of the process eliminates production bottlenecks and ensures consistent quality.

Versatility of applications

The ability to process a variety of paper formats from 148.5 x 210 mm to 330 x 480 mm and handle materials up to 25 sheets makes the booklet maker suitable for a wide range of applications.

Technical parameters of modern broaching

Precision manufacturing

Modern booklet making systems ensure accuracy of +/- 0.5 mm, which guarantees a professional appearance of the final product. Accurate sheet positioning and precise face cutting eliminate the need for additional machining.

Configuration flexibility

The possibility of using different thicknesses of creasing strips (0.6, 1.0, 1.2, 1.4 mm) and optional expansions with cross perforators, linear perforators or barcode readers allow the system to be adapted to specific production requirements.

Material efficiency

The ability to sew 2-25 sheets of 80 gsm material and cut up to 48 sheets plus a 128 gsm cover allows the production of both thin flyers and thick catalogs.

Trends in the development of booklet technology

Modern booklet making is evolving toward even greater automation and integration with digital systems. Developments in digital printing technology require adapting sewing heads to the specifics of digital toners and inks. Smart production management systems optimize workflows and minimize waste.

Bookleting remains one of the most important bookbinding techniques, combining traditional quality workmanship with modern production efficiency. Investing in advanced booklet-making systems is a strategic decision that can significantly increase a company's production capacity and competitiveness in the printing industry.