Spiraling - calendars, notebooks

We specialize in supplying spiral binding equipment - for the production of calendars, notebooks and all other spiral bound printed matter.

Perforators can be equipped with tools in different standards - 3:1, 2:1 - square, eyelets - with or without a tear cut under the calendar.

Clamping machines tighten spirals - from the simplest hand-held desktop devices to advanced, tool-quick and reliable production semi-automatic and fully automatic systems.

Spiral machines

Perforators

-

ONYX HD7725H ULTIMA perforator

-

ONYX HD7725 Ultima perforator

-

Tornado Autopunch EX Automatic Perforator

-

Automatic perforator FAR 4-42

-

Automatic perforator FAR 5-55

-

Perforator Super 600

-

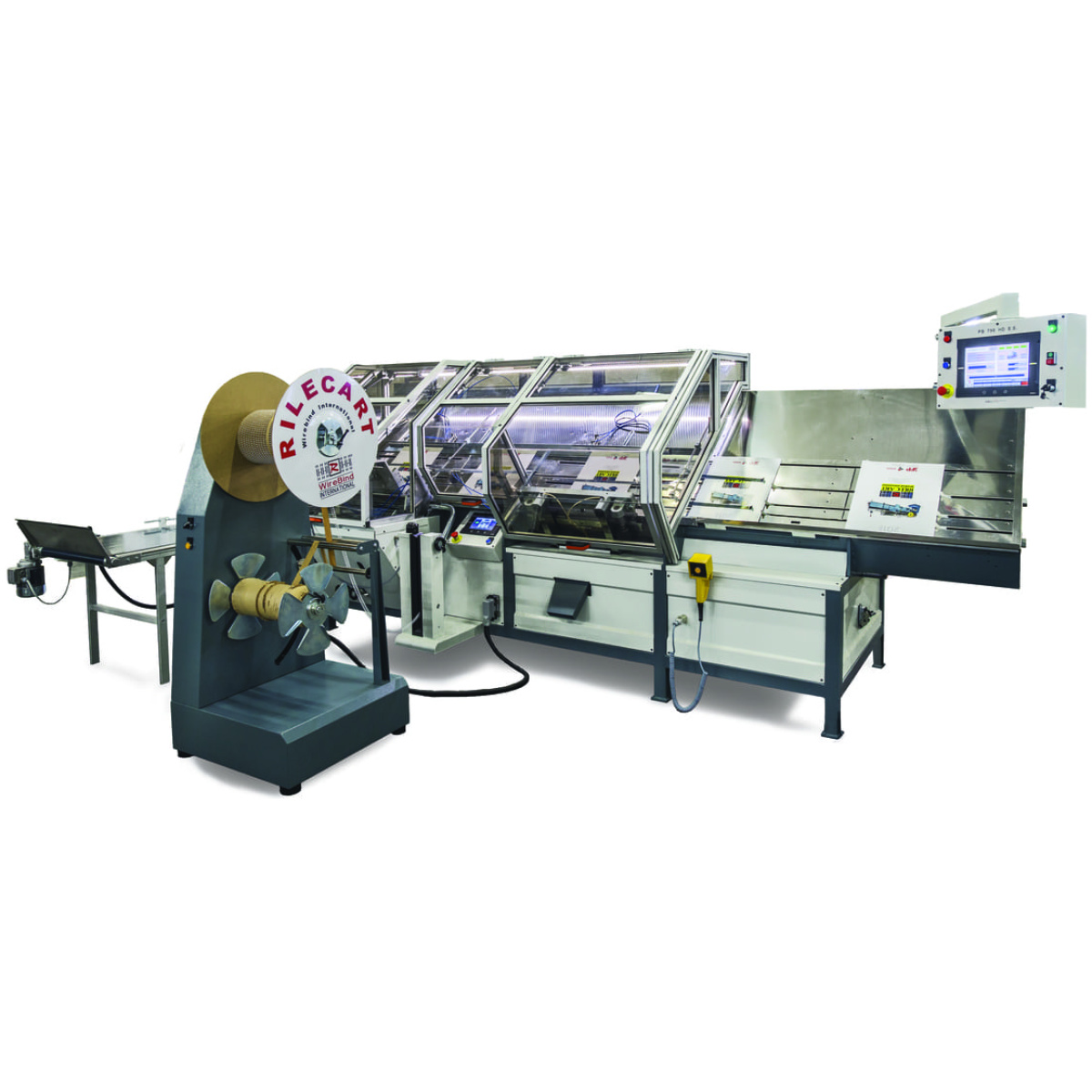

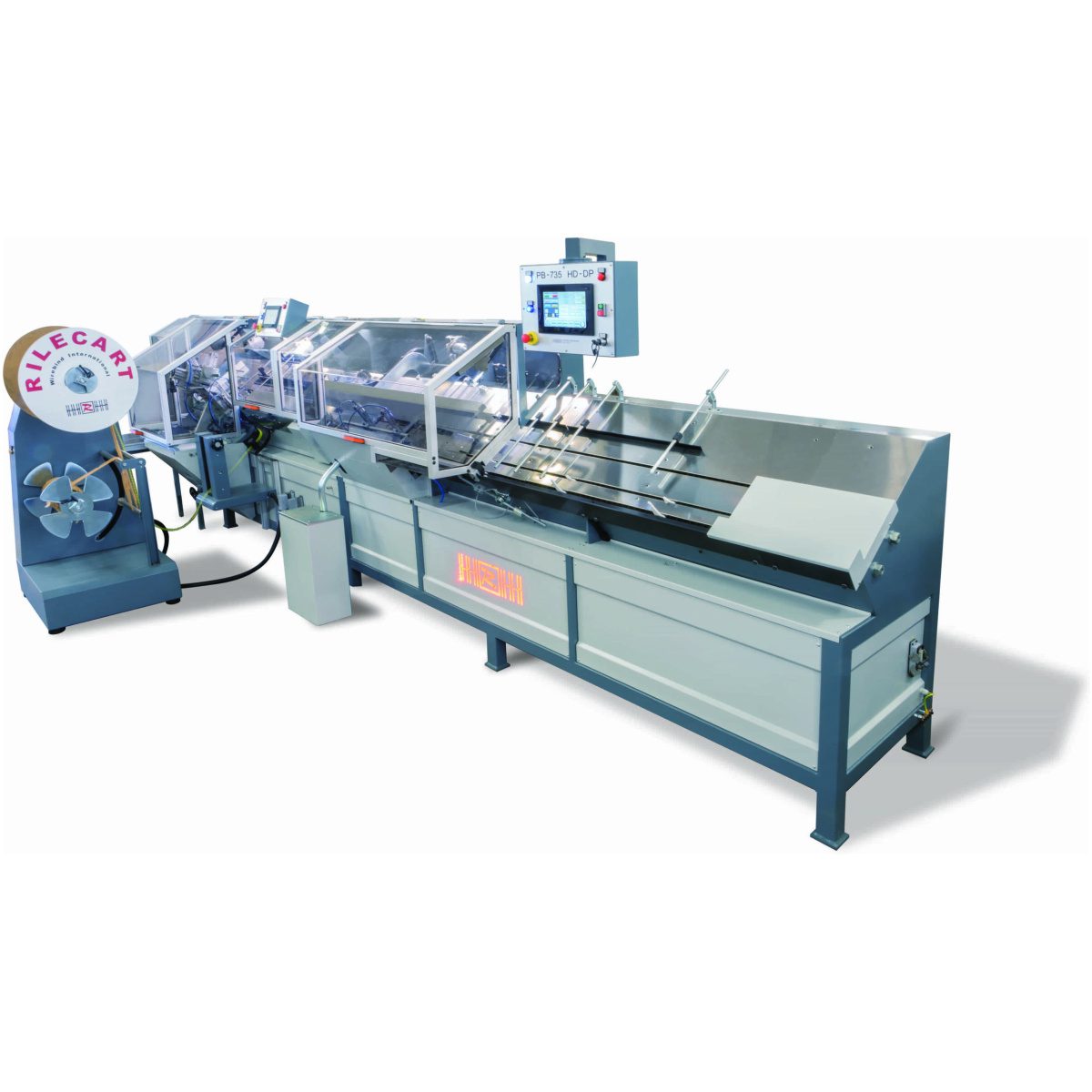

RileCart Linea 500 and Linea 800 perforator

-

Perforators Rhino-o-tuff HD7700 - 356mm

-

Rhino-o-tuff HD7500 perforator - 610mm

Spiral closers

Spiral binding - a comprehensive guide to spiral binding

What is spiraling and why is it gaining popularity?

Spiral binding is one of the most versatile methods of bookbinding, which involves running a metal or plastic spiral through holes perforated in a set of pages. This method of binding is characterized by exceptional functionality - bound documents can be completely opened flat and even turn the pages 360 degrees, which makes them extremely practical for use.

The growing popularity of spiral binding is due to its versatility of applications and relatively low production costs. Unlike hardbound or glued binding, spiral binding does not require specialized adhesives or long drying times, which allows for quick turnaround of orders while maintaining the high quality of the final product.

Types of spirals and their applications

Metal spiral (double wire)

The metal spiral, made of high-quality steel wire, is characterized by exceptional durability and resistance to deformation. Available in various colors and diameters, it is ideal for products that require frequent use, such as desk calendars, professional notebooks or technical manuals. Closing the metal spiral requires specialized tools, but the end result guarantees long-lasting functionality.

Plastic spiral

Plastic spirals offer a greater variety of colors and are a more economical option for products with a shorter shelf life. Particularly popular in promotional materials, reports or presentations where aesthetics and cost are key decision factors.

Screw-on luminaire

A special type of spiral binding in which the spiral is "screwed" onto sets of sheets without perforation. This method works especially well for products of small thickness or materials requiring quick binding without additional processing.

Perforation standards in spiraling

Standard 3:1 (3 holes per inch)

The 3:1 standard features denser perforation for more stable spiral attachment and better binding strength. It is ideal for thicker publications and heavily used products. Square-shaped perforations ensure precise spiral guidance and minimize the risk of paper tearing.

Standard 2:1 (2 holes per inch)

The 2:1 standard offers less frequent perforation, making it suitable for thinner materials or products where aesthetics are a priority over maximum strength. The greater distance between holes reduces paper weakening, which is especially important for delicate materials.

Special hole shapes

Eyelet or teardrop-cut holes for calendars are specialized solutions tailored to specific applications. The teardrop cutout allows for easy flipping of calendar pages, while the eyelets provide extra strength in the most stressed areas.

Step by step spiral process

Perforation of the material

The first stage of spiraling is the precise perforation of a set of cards using specialized perforators. Modern perforators, such as the ONYX HD7725 series, provide precise hole positioning and can process a variety of material thicknesses - from single sheets to stacks of significant thickness.

Driving the spiral

The spiral is inserted through perforated holes using automatic or semi-automatic spiral systems. Advanced automatic machines, such as the PB-796 HD series, can handle large formats and provide precise spiral guidance without risk of material damage.

Closing the spiral

The final step is to close the spiral using specialized closers. This process involves bending the ends of the spiral in a way that prevents it from slipping out of the holes. Professional closers of the R-800 series ensure precise and aesthetic closing of the spiral.

Applications of spiraling in various industries

Advertising and marketing industry

Corporate calendars, promotional notebooks and product catalogs are the primary uses of spiral binding in the advertising industry. The publication's ability to open fully flat makes them ideal for presenting products or schedules, and the variety of spiral colors allows them to match a brand's visual identity.

Education sector

Scripts, teaching aids and workbooks often use spiral binding because of its functionality. The ability to turn the pages 360 degrees is especially useful for taking notes or working with text when the publication needs to be folded in half.

Office and corporate applications

Spiral-bound reports, presentations and technical documentation combine a professional appearance with practicality of use. Spiral binding makes it easy to update documents by replacing individual pages without having to re-bind the whole thing.

Technical parameters of modern spiral systems

Performance and speed of operation

Today's spiral automatic machines reach a capacity to bind hundreds of publications per hour. Semi-automatic systems offer a compromise between productivity and investment costs, while full automats provide maximum productivity with minimal operator input.

Flexibility of formats

Modern spiral systems can handle formats from small notebooks to large wall calendars. The ability to change tools and settings quickly allows efficient production of a variety of products without long changeover times.

Precision and quality workmanship

Advanced control systems ensure precise spiral positioning and even tension throughout the binding. Automatic controls compensate for variations in material thickness, ensuring consistent quality regardless of the type of product being bound.

Spiral binding remains one of the most versatile and practical binding methods. The choice of the right equipment - from perforators to spiral machines to closers - determines the efficiency of production and the quality of final products. Investment in professional spiral binding systems is a step toward expanding the portfolio of services and increasing competitiveness in the functional products segment.