What are printing machines?

Printing machines are specialized industrial equipment used for print production and finishing. In a broad sense, they include all the machinery used in the printing process - from the equipment that prepares materials for printing, to the printing machines themselves, to the advanced finishing systems that give the product its final shape and functionality.

Modern printing is an interdisciplinary field combining technology and art, encompassing the processes of repeated reproduction of images and text on a variety of substrates. It is thanks to printing machines that books, magazines, packaging, labels, advertising materials and countless other everyday products are created.

Types of printing machines

Printing machines can be divided into three main categories, corresponding to the stages of production:

Prepress Machines - prepress equipment, including CtP (Computer-to-Plate) systems for producing print forms, plotters for proofing and imposition software and file preparation.

Press (printing) machines - equipment for applying ink to the substrate, such as offset, digital, flexographic, screen-printing or rotogravure machines.

Postpress (finishing) machines - the broadest category including equipment for processing printed materials: guillotines, creasing machines, folding machines, binders, booklet makers, laminators, UV varnishers, gilders and many others.

It is worth noting that while printing is the centerpiece of the technology, it is the advanced finishing machines generate a significant part of the product's added value, translating into its durability, aesthetics and uniqueness.

Three Pillars of Print Production

To fully understand the role of individual printing machines, it is crucial to understand the structure of the production process:

Prepress (Preparation for printing)

The phase in which digital graphic design is transformed into a print-ready form. It includes file verification (preflight), production of certified proofs, imposition of pages on printing sheets and preparation of print forms. Offset technology uses CtP (Computer-to-Plate) equipment, which exposes aluminum plates for each CMYK color.

Press (Printing)

The heart of the process, in which ink is applied to the substrate using printing machines. The operator (printer) assembles the printing molds, configures the paper and ink feeding systems, and then supervises the process, controlling color matching and print quality. Here, quality control and maintaining production stability are key. In the matrixless printing process - digital - there are no matrices and printing is done using the image created by toner or ink/ink.

Postpress (Finishing)

The last, but extremely important stage, which often determines the final value of the product. Printed sheets undergo a number of operations: cutting on guillotines, folding on folding machines, creasing on creasing machines, picking on gathers, binding on wrapping machines or booklet makers, as well as finishing with UV varnishers, foilers or gilders.

Modern printing is increasingly moving away from the model of separate, independent machines. The dominant trend is toward automation and integration - modern multifinishers combine cutting, creasing and perforating in a single cycle, while advanced systems read barcodes on the sheets to automatically configure themselves for a given job. Akonda.pl as a leading supplier of printing machines offers the latest integrated solutions that dramatically increase production efficiency and profitability. Our Duplo brand multifinishers are a guarantee of automation at the highest level.

Main Types of Printing Machines

Choosing the right printing technology has a direct impact on the selection of finishing machines. Each technology generates different requirements for postpress processes.

Classification by printing technique

Offset machines - The most popular technology in commercial printing. The image from a flat printing mold is transferred to a rubber cylinder and then to the substrate. It provides high quality and is very efficient for large runs of books, magazines, catalogs and posters. After printing, offset sheets require professional finishing - Akonda.pl offers all the necessary postpress machines for their processing.

Digital printing machines - Technology without fixed print forms. The image is created from digital data for each print. It is divided into laser (thermally fused toner) and inkjet (micro ink droplets) technologies. Ideal for low print runs and personalization, but requires special creasing machines with systems to prevent toner breakage. Akonda.pl specializes in solutions for digital printers - We offer complete sets of finishing machines ideally suited to this technology, including paper folding systems that eliminate the problem of toner cracking.

Flexographic machines - They use flexible, relief printing forms. They dominate packaging and label production, enabling printing on films, corrugated cardboard and plastics. They work with roll-stockers and roll plotters. At Akonda.co.uk you will find complete solutions for the packaging industry - as of rotary barbells to machines for manufacturing luxury packaging.

Screen printing machines - Paint pressed through a die with a pattern. Allows to apply a thick layer of paint with intense colors. Used for textiles, gadgets and print finishing.

Rotogravure machines - They use cylinders with an engraved image. Superior quality and tremendous speed, but high cost of mold preparation. Used for high-volume magazines and packaging.

Classification due to the form of the substrate

Sheet Machines - Print on single sheets taken from a stack. Standard in commercial and job printing (flyers, posters, business cards).

Coil (roller) machines - Print on a continuous web of roll paper. Much higher speed, used for newspapers, magazines and labels. They require special cutting machines that first cut the web into sheets.

Comparison of printing technologies

| Technology | Operating Principle | Main Advantages | Main Disadvantages. | Typical Applications |

| Offset | Indirect transmission through a rubber cylinder | High quality, low cost at high volumes | High cost of preparation, not cost-effective for small expenditures | Books, magazines, catalogs, flyers |

| Digital | Direct nesting from digital data | Cost-effectiveness from 1 piece, personalization, quick start | Higher cost at high expense | Low-volume printing, photo-albums, on-demand printing |

| Flexography | Flexible convex form | Printing on a wide range of substrates, high speed | Lower quality details | Labels, packaging, bags |

| Screen printing | Squeezing paint through a sieve | Thick layer of paint, intense colors | Low speed, limited resolution | Textiles, gadgets, refining |

The Printing Process Step by Step: From Design to Finished Product

Stage 1: Prepress - Digital Foundations

It all starts with graphic design. The tasks are largely digitized:

- Design and Verification (Preflight) - checking the file from a technical point of view (resolution, CMYK color space, bleeds)

- Proofing - making a certified sample print as a color master

- Imposition - arranging the pages on the printing sheet in the correct order

- Production of printing forms - exposure of offset plates in CtP system, separate form for each color

Stage 2: Press - Transferring the Image to Paper

- Machine organ - Assembly of molds, setting of paper feed, filling of inkwells

- Printing - applying successive colors in printing units

- Quality control - constant supervision of color matching and saturation

Stage 3: Postpress - Making the Final Form.

After printing, the sheets go to the bindery department:

- Slicing On guillotines - cutting large sheets into smaller uses

- Bending on folding machines and creasing machines - folding sheets and making creases

- Completing on collectors - arranging contributions in the correct order

- Binding On wrapping machines, booklet makers or hard binding systems

- Refining - lamination, UV varnishing, gilding

- Finishing - trimming on tripods, rounding corners, numbering

Print Finishing Machines (Postpress) - Comprehensive Review

The machinery of the postpress department is as diverse and advanced as the printing machines themselves. It is this equipment that determines the quality, durability and final appearance of the product.

Preparing for Binding: Cutting and Bending

Guillotines - Slicers

Fundamental printing machinery in every print shop, used to precisely cut large stacks of paper into smaller, desired formats. Equipped with sharp steel knives and pressure systems, they provide even and clean cutting edges for flyers, posters or book blocks. Akonda.co.uk offers guillotines from basic electric models to advanced programmable industrial guillotines With safety systems and automatic clamping. We can help you select the perfect model for your production scale and budget.

Biggers

Biggers are devices that perform creasing - kneading a special groove (crease) in paper or cardboard, which facilitates precise bending of the material. This process is indispensable when working with higher-weight materials (above 170 gsm), book covers or invitations, as it prevents unsightly cracking of paper fibers and toner. Akonda.pl offers a wide range of creasing machines - from compact table-top models to professional machines with automatic feeding and Tech-ni-fold systems, which are indispensable in digital and offset printing plants.

Biggers

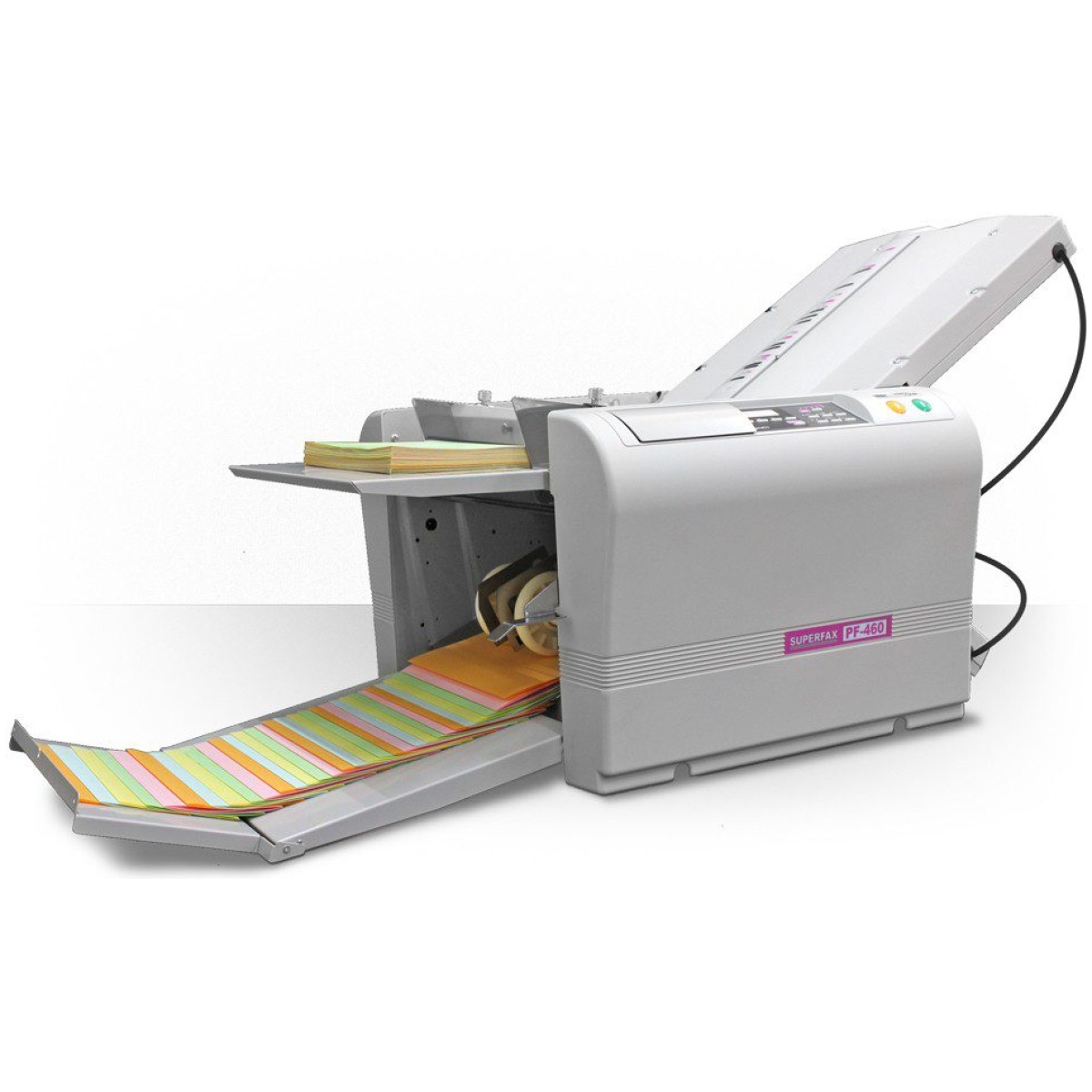

Folders

Folders are used to automatically fold (fold) sheets of paper. There are two main types: cassette folders (ideal for standard, lower-weight papers) and knife folders (allow thicker and stiffer materials to be folded by using a knife to press the sheet between the rolls). Key in the production of flyers, brochures and book folds. At Akonda.pl we offer professional folding machines of renowned brands, which will provide precise folding at high productivity. Our models handle both thin office papers and thick cover stock.

Folders

Folding machines

Integrated systems that first crease a sheet and then fold it in a single pass. This combination of operations is ideal for processing thicker papers, covers with wings or greeting cards, guaranteeing the highest quality of creasing.

Creating Multipage Products: Binding and Brochure Making

Brochure

Brochures are automated lines for the production of booklets in notebook binding. The machine collects the folds in a single cycle, staples them to the spine with a wire, folds them in half and often also front-cuts them to create the finished product.

Products by category

Collectors

Collectors are machines whose job is to automatically complete printed sheets or folds in the correct order, forming a ready-to-bind block of a book or catalog. They eliminate time-consuming and error-prone manual picking.

Peelers (Softcover)

Specialized printing machinery For glued binding. The process involves milling the spine of the book block, applying hot glue (EVA hot-melt type) and bonding the block to the soft cover. Advanced models have separate systems for side gluing, which drastically increases the durability of the binding and prevents pages from falling out. Akonda.co.uk is an expert in edge banding machines - In our offer you will find edge banding machines from compact models for small printing houses to industrial lines with automatic feeding of covers and PUR system (polyurethane glue of the highest durability). We will help you choose the perfect edge binder for your book production, catalogs and magazines.

Hard Binding Machines

Systems designed for the production of hardbound (cardboard) books. The process involves the application of glue to the veneer, the precise placement of cardboard (facings and spines) and the wrapping of the edges of the veneer.

Spiralizers

Spiralizers are devices for perforating the edges of sheets and screwing a metal or plastic spiral into the holes. This method of binding, popular for calendars, notebooks and training materials, allows the publication to open fully 360 degrees flat.

Innovative Systems and Specialized Technologies

Fastbind

Fastbind is an innovative tabletop system for professional book bindings, in both softcover and hardcover. It is an ideal solution for digital printers, service outlets and photographers to quickly and profitably produce on-demand books, photo-albums and personalized publications without complex organs. Akonda.pl is an authorized distributor of Fastbind systems in Poland - We offer a full range of the brand's equipment along with training, consumables and service. The Fastbind system is ideal for companies that rely on on-demand printing and short runs.

Lay flat Binding

A revolutionary bonding technology that allows you to create books and photo-albums that open perfectly flat (180 degrees). Unlike traditional binding, in lay flat does not have a deep groove in the spine, which allows you to place panoramic photos on the entire spread without losing a piece of the image. Premium technology dedicated to the most prestigious publications. Akonda.co.uk offers complete lay flat album production solutions - From gluing machines, to presses, to consumables. We will help you enter the premium photo-album market, which generates the highest margins in the industry. We provide training and full technical support.

Tech-ni-fold

Specialized, patented creasing tools and systems mounted on existing folders or creasing machines. Their unique design with flexible rubber inserts eliminates the problem of paper and toner fiber breakage, which is crucial in the processing of digital prints and coated materials.

Automation and Final Finishing

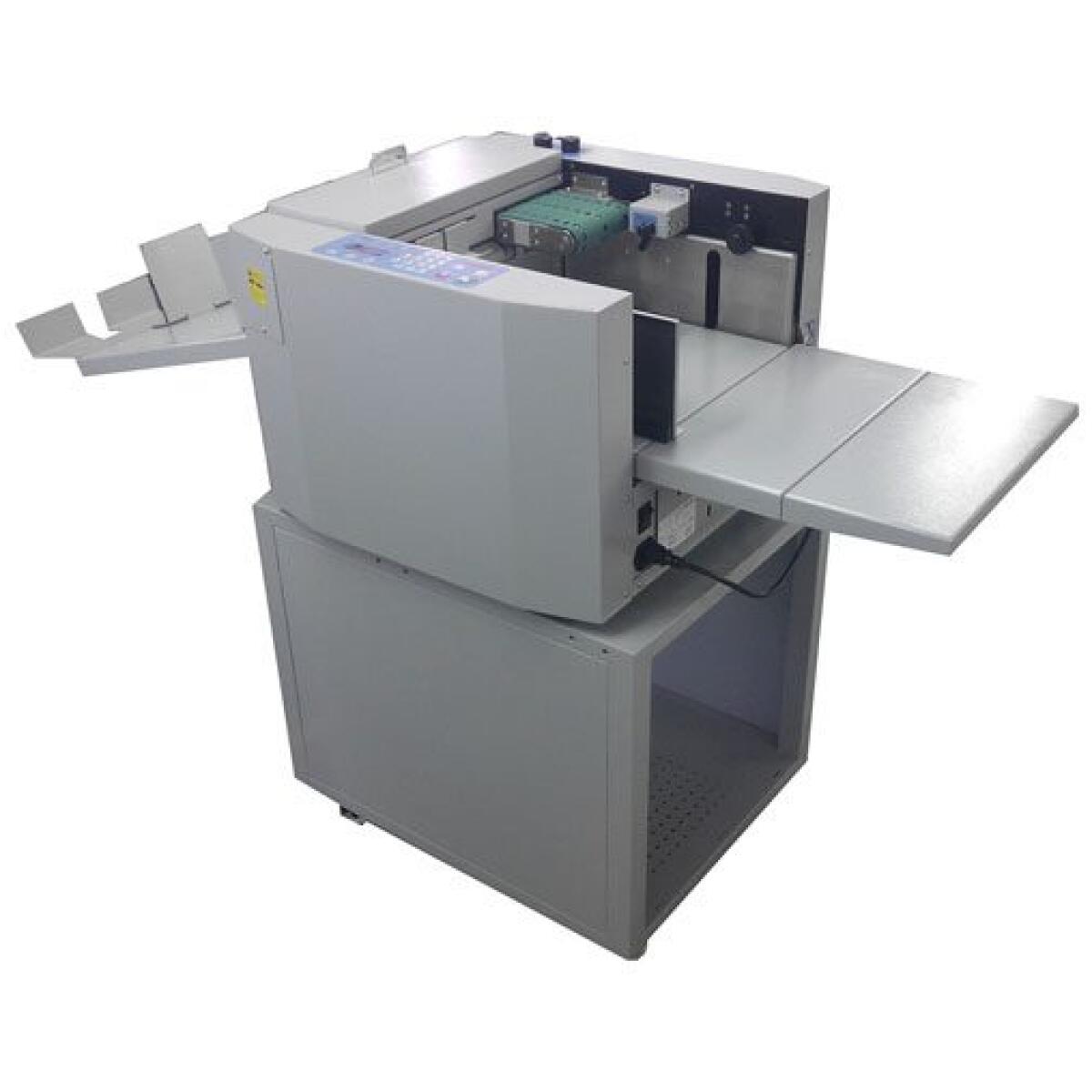

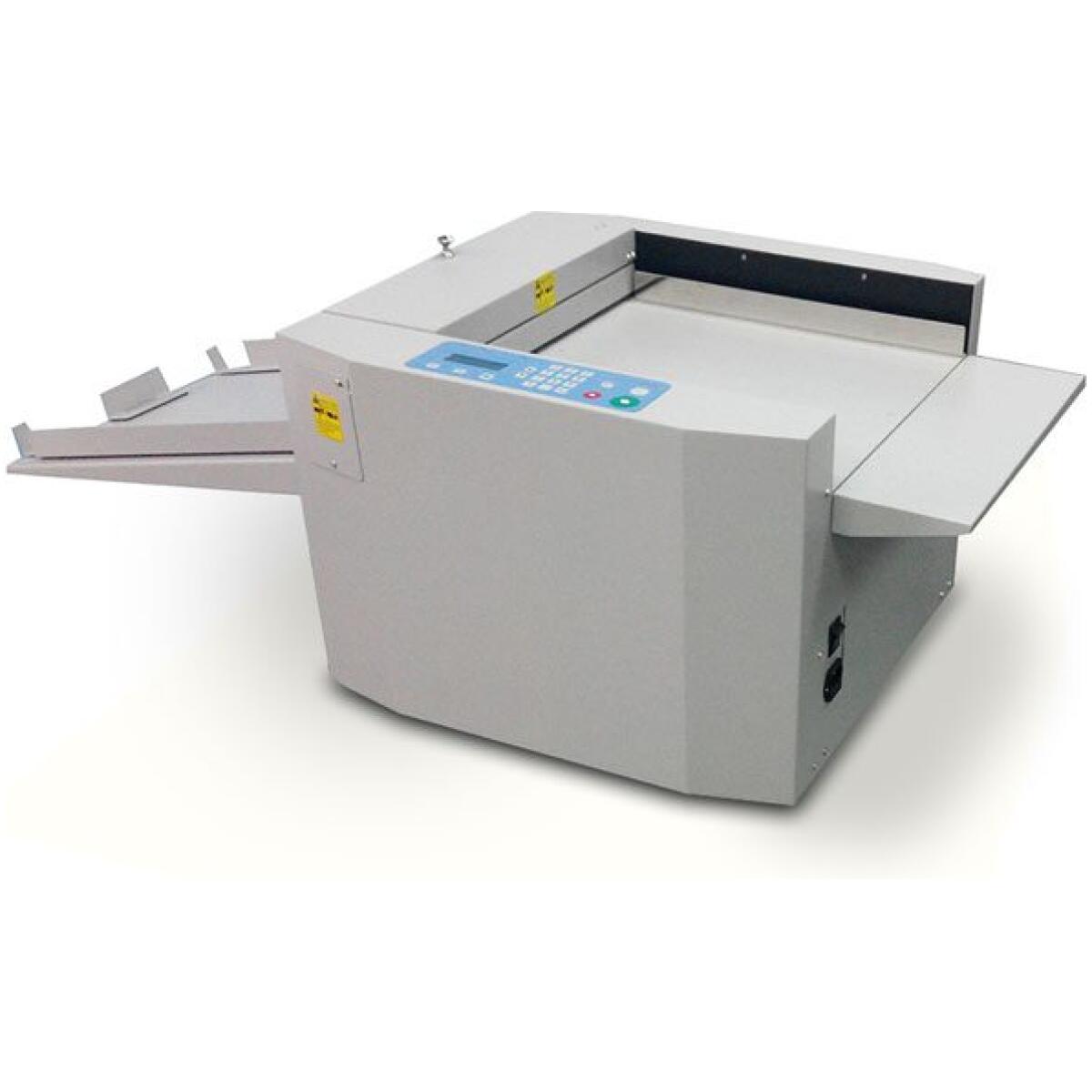

Multifinishers

Integrated systems that perform multiple operations in a single sheet run: slitting (cutting), cross-cutting (slicing), creasing and perforation. Multifinishers are indispensable for digital printers to quickly produce business cards, flyers, coupons or postcards, drastically reducing turnaround time. Akonda.co.uk is the official distributor of multifinishers. Our devices are equipped with barcode reading and automatic configuration systems, eliminating the need for manual programming. It's an investment that pays for itself in a few months through time and labor cost savings.

Cutting Plotters

Computer-controlled equipment equipped with a blade that precisely cuts any shape from sheets of material - paper, self-adhesive film or cardboard. Used to produce stickers, stencils and packaging prototypes.

Products by category

Roller Plotters

A specialized version of plotters that works with roll material, ideal for producing large runs of stickers, labels and advertising materials.

Rol-strippers (Rotary punching machines)

Highly efficient printing machinery for die-cutting, creasing and perforating, in which the tool is a flexible die-cutter on a rotating magnetic cylinder. They enable continuous operation at high speed and are much faster than traditional flat die-cutters, ideally suited for packaging and label production.

Business Card Cutters/Binder Combos

Specialized, automated machines that cut an entire sheet printed with business cards in a single pass. Modern models offer additional functions: creasing (for folded business cards), perforation or marker reading for precise positioning of the cut.

Trinity

Precision bookbinding machinery Used for the final three-sided trimming of a book block or booklet stack. They ensure perfectly even and smooth edges of the finished publication, giving it a professional look.

Refining and Supplementary Operations

UV varnishes

UV varnishes are devices for applying UV-cured liquid varnish to the printing surface. This process not only protects the print from abrasion and moisture, but also gives it a high gloss. It is possible to varnish the entire surface or only selected elements (selective varnish). At Akonda.pl you will find professional UV varnishers For full-stack and selective varnishing. We offer equipment ranging from compact offline models to integrated inline systems. UV varnishing is a high-margin service that will allow you to add value to your products and stand out from the competition.

Foil/Laminators {#Foils}

Foiling machines They are used to cover prints with a thin layer of film (glossy, matte, soft-touch), which significantly increases their durability, stiffness and resistance to external factors, as well as enhances aesthetic qualities.

Gilders

Hot-stamping machines (hot stamping), which uses a heated die to press metalized or colored foil into the substrate. This technique makes it possible to achieve exclusive metallic decorations on invitations, covers or packaging.

Corner Rounders

Simple, but very useful devices for aesthetically rounding corners in business cards, menu cards, calendars or invitations.

Numberers

Devices (manual or automatic) for stamping consecutive numbers on documents, tickets, coupons or invoices, providing unique identification of each copy.

Sheet Counters

Precision printing machinery For fast and error-free counting of sheets of paper in a stack. Essential for circulation control, inventory and preparing material for further production.

Luxury Box Manufacturing Machinery

Automated systems for producing high-quality cardboard packaging. They perform creasing, notching, cutting and gluing in a single cycle, enabling the production of on-demand boxes that are perfectly matched to the product.

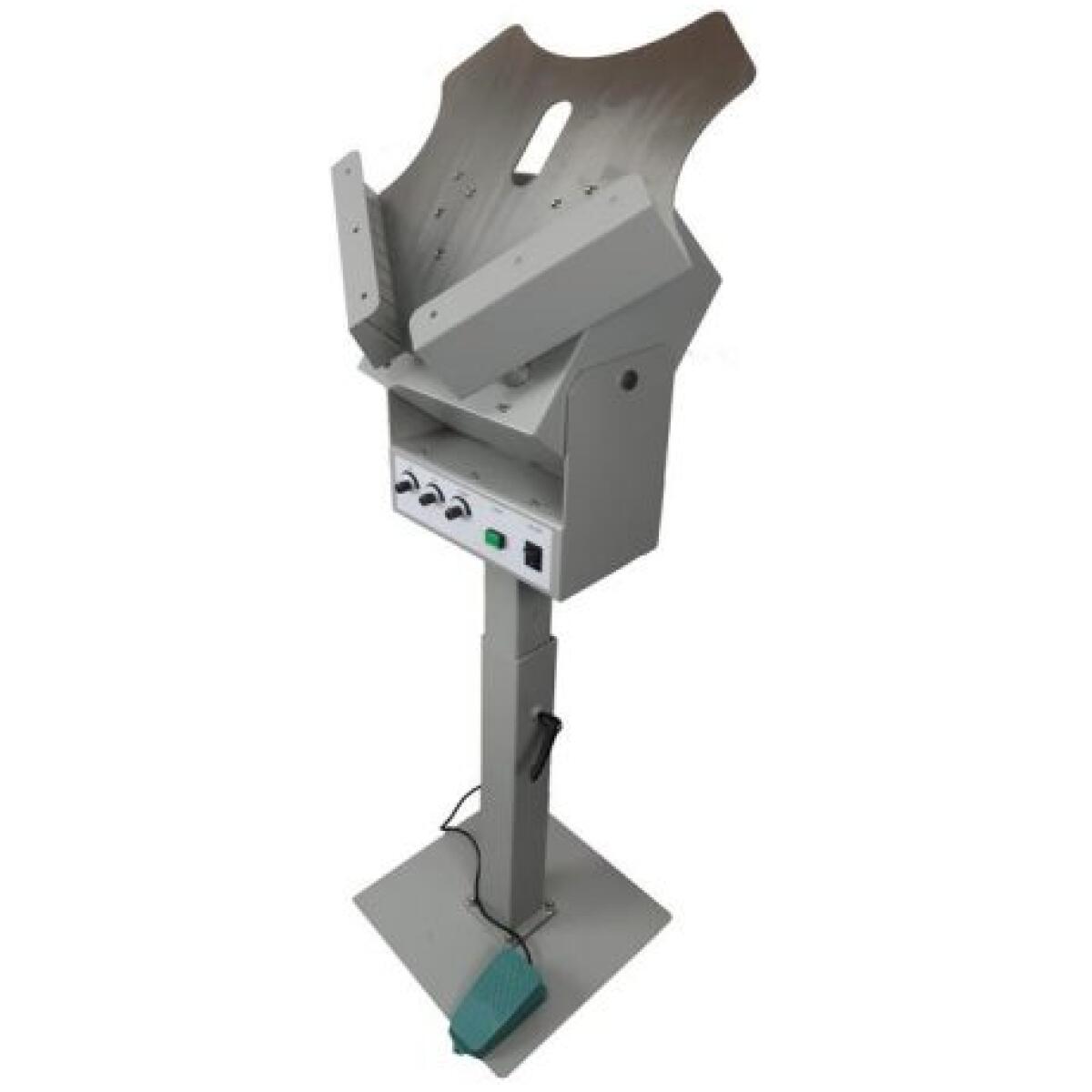

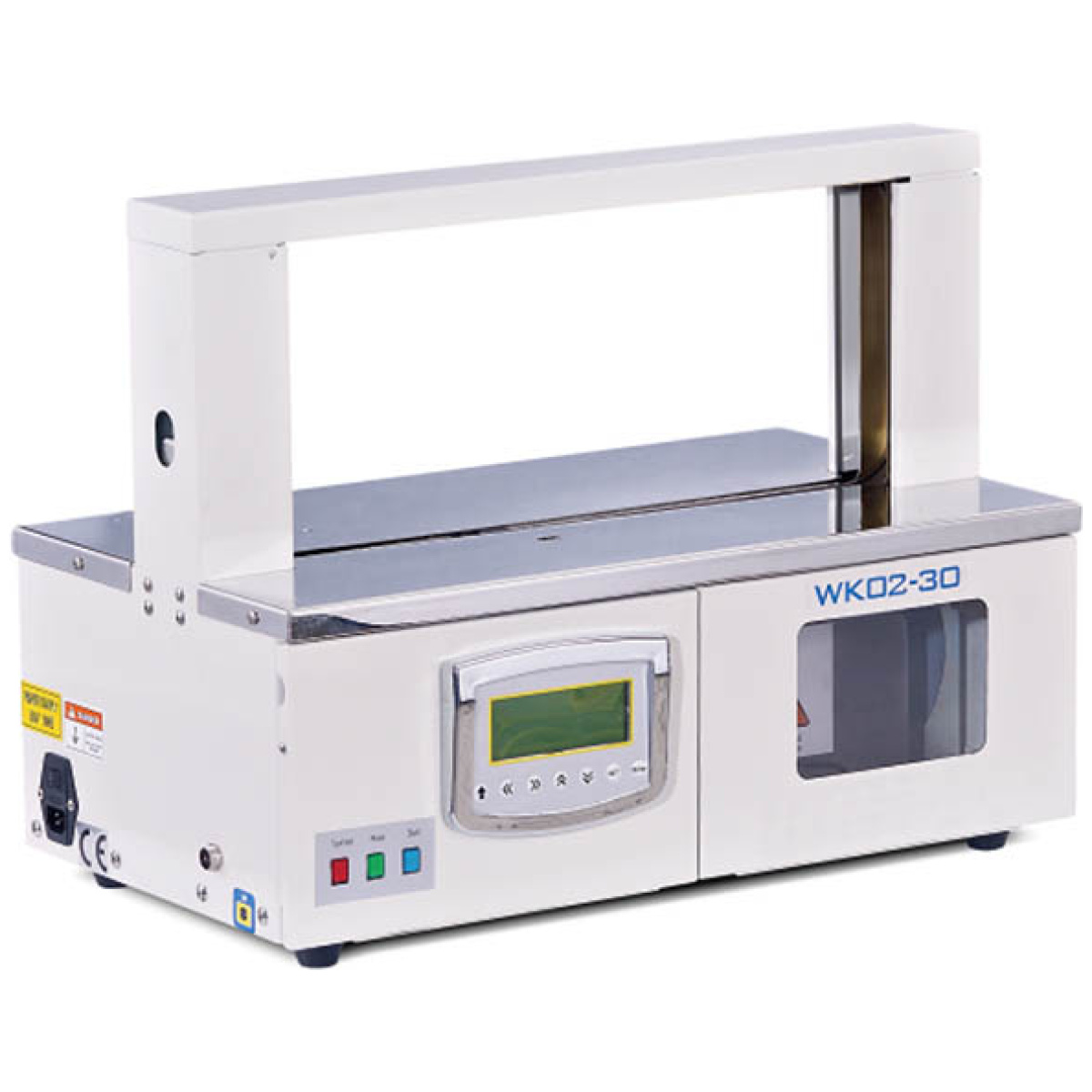

Banding machines

Banding machines are machines used to wrap products, stacks of leaflets or business cards with paper or foil tape (banderole), making them easier to pack, transport and distribute.

Anatomy of an Offset Machine - What's Hidden Inside?

Understanding the construction of printing machines allows one to appreciate the degree of their technical sophistication. Analyzing the structure of a sheet-fed offset machine, it is possible to distinguish universal functional assemblies found in most equipment.

Main assemblies of the printing machine

Feeding unit (Self-feeder and trailing table) - Precisely picking a sheet from a stack and delivering it to the printing unit. It consists of a system of suction nozzles, separation blowers and conveyor belts.

Printing unit - The heart of the machine, where the image transfer takes place. In offset, it consists of three cylinders: the form cylinder (with the printing plate), the intermediate rubber cylinder and the pressure cylinder (presses the paper). Each color requires a separate unit.

Ink and wetting units - complex roller systems that spread the ink into a thin layer and apply it to the printing mold. A wetting unit provides an aqueous solution that protects the non-printing parts of the plate.

The team of leading and receiving sheets (Lecture) - Transporting the printed sheet and placing it on the receiving stack. A system of grippers and chains guides the sheet through successive assemblies, while an exponent places the prints on the pallet.

Modularity principle

The principle of modularity, evident in the design of an offset machine, is fundamental to the entire printing industry. Each machine - from the guillotine to the wrapping machine - is a specialized module for a specific task. Understanding this logic allows you to consciously build your machine park as a cohesive, integrated ecosystem.

Production line planning involves selecting and combining the right modules to create an efficient and flexible workflow capable of handling a wide range of orders. Akonda.pl team will help you design the optimal configuration of printing machines for your print shop, taking into account the specifics of production, available space and investment budget.

How to Choose Printing Machines for Your Business?

The world of printing machinery is complex and dynamic, driven by technological advances and changing market demands. Modern printing is much more than just printing - the key to success today is becoming efficiency, quality and versatility of finishing processes.

Key factors in choosing machines

Production specifics - Is your main profile job job printing, book production, packaging or labels? The answer determines whether the priority will be a booklet maker, a hardcover binder, or a multifinisher.

Supported technologies and materials - The postpress machine park must be compatible with printing machines. Digital printing will need solutions to prevent toner breakage, and a company working with thick cardboard boxes - efficient creasing machines and guillotines. Akonda.co.uk experts will analyze your machinery and suggest the perfect complement - Finishing machines fully compatible with your printing technology.

Degree of automation and scale of operations - Small printers can use semi-automatic equipment. For large volumes, investment in automated, integrated production lines (multifinishers, booklet makers) becomes a necessity.

Opportunities for growth and diversification - When choosing machines, it is worth thinking ahead. Equipment that allows you to expand your offerings with new products - luxury packaging, photo-albums in LayFlat binding, prints enhanced with UV varnish or gilding - can become a driving force for growth.

An investment in the future

The wide range of finishing machinery is a direct response to the evolution of the printing market. Printers, in order to remain competitive, must move away from mass production to diversify their offerings and provide niche, high-margin products. Investment in advanced postpress technologies is becoming a strategic necessity - enabling the creation of high-value-added products that stand out in the market and generate higher profits.

Choosing the right printing machinery is an investment in quality, productivity and business profitability. From basic guillotines and folding machines, to advanced binders and booklet makers, to specialized LayFlat UV varnish systems, each machine plays a key role in the creation of final products.

Akonda.pl - Comprehensive Solutions for Your Printing House

In the maze of available technologies and solutions, the support of an experienced partner is invaluable. Akonda.pl is a leading supplier of printing machines in Poland, specializing in professional print finishing equipment. Our long-standing presence in the market and hundreds of satisfied customers is a guarantee of reliability and professional advice.

Why should you choose Akonda.pl?

Comprehensive range of finishing machines - In our portfolio you will find all the necessary postpress equipment: from basic guillotines and creasing machines, through advanced binders and booklet makers, to specialized lay flat systems and UV varnishers.

Technical advice at the highest level - Our experts will help you select the optimal printing machines for your specific production. We analyze your needs, print runs, job types and budget to suggest solutions that provide the best return on investment.

Reputable manufacturers - We cooperate only with recognized manufacturers of printing machines, which guarantees the highest quality, reliability and long life of equipment. In Akonda.pl offer you will find Duplo brand multifinishers, innovative Fastbind systems, precision guillotines and many other proven solutions.

After-sales support - Our care does not end with the delivery of the machine. We provide operator training, technical service and ongoing support to keep your machines running smoothly and efficiently.

Our specialties

For digital printers - We offer complete solutions adapted to the specifics of digital printing: creasing machines with systems that eliminate toner cracking, high-speed multifinishers for the production of business cards and flyers, automatic business card cutting machines and universal creasing and folding machines.

For book and catalog producers - Comprehensive bindery lines: professional binders with side gluing system, efficient booklet makers for staple binding, precise collectors for folding, hardcover binding systems and innovative Fastbind solutions for on-demand book printing.

For photo-album producers - exclusive lay flat technology to create albums that open perfectly flat, Fastbind systems for quick photo-album production, and UV varnishers to protect and enhance photos.

For packaging manufacturers - advanced roll-stitchers for die-cutting and creasing, cutting and roller plotters for precision die-cutting, machines for producing luxury boxes, and film machines for laminating packaging.

For jobbing printers - Universal guillotines for cutting all formats, efficient folders and flyers folders, spiral folders for notebooks and calendars, UV varnishers and gilders for finishing invitations and rounders of corners.

Solutions for every scale of business

For small printers and service outlets - We offer compact, table-top solutions ideal for getting started: the Fastbind system for on-demand binding, table-top guillotines, manual and semi-automatic creasing machines, spiral binders and rounders.

For medium-sized printers - Comprehensive job equipment: professional programmable guillotines, automatic folding machines and creasing machines, multifinishers for fast finishing, binders for small and medium print runs, and finishing equipment.

For large manufacturing plants - Automated production lines: high-capacity booklet makers, advanced binders with automatic cover feeding, hardcover binding systems, multi-stand collectors, industrial triple knives and roll-stands.

Investment in development with Akonda.co.uk

We understand that the purchase of printing machines is a serious business decision. That is why at Akonda.pl we approach each customer individually. Our consultants will analyze your current situation, development plans and the specifics of the local market in order to propose optimal solutions.

Increase your competitiveness - By investing in modern finishing machines from Akonda.pl's offer, you gain the possibility to realize a wider spectrum of orders. UV varnishers and gilders will allow you to offer finishing, lay flat systems - prestigious photo-albums, and multifinishers - express production of small print runs.

Automate production - Replacing several manual operations with a single integrated machine (multifinisher, creasing machine, booklet maker) dramatically reduces turnaround time, lowers labor costs and minimizes the risk of errors.

Raise the quality - Professional printing machines from Akonda.pl guarantee repeatability and precision. Big machines or Tech-ni-fold systems eliminate cracking of digital prints, precision guillotines ensure perfect edges, and edge binders with side gluing ensure durable binding.

Contact us today

If you are considering:

- With the purchase of the first machines for the new printing plant

- Modernization of the existing machine park

- Expanding the offer with new products (lay flat photo albums, packaging, finishing)

- Automation of finishing processes

- Moving to a higher level of quality and efficiency

Akonda.pl team is at your service. Contact our experts for a free consultation and quote tailored to your needs. We can help you build or modernize a fleet of printing machines that will become the foundation for your company's success in the booming printing industry.

Akonda.pl - Professional printing machines for professionals.