C.P. Bourg, a Belgian manufacturer of solutions for stapling booklets and gluing EVA/PUR soft bindings in mid-May during a 4-day event presented the latest solution from its portfolio - the BPM module.

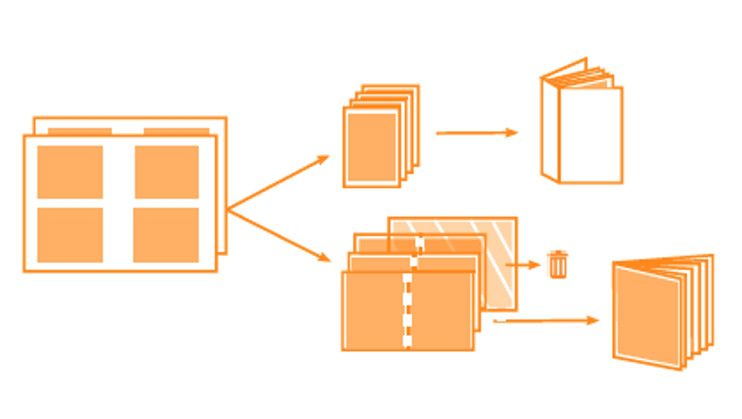

The BPM module is a unique and innovative solution in sheetfed printing that allows you to fold in half, rotate, slit in half a sheet that is fed directly from the printing machine or feeder. BPM is a configurable element under the type of production in the printing house, there are more than 40 configurations that allow the implementation of various jobs.

With the BPM module at SRA3 printing, for example, you can make:

- glued bindings in a format similar to A4 (2 uses of a sheet)

- glued bindings in a format similar to A5 (4 uses from a sheet)

- A5 brochures (4 uses per sheet)

- A6 brochures (8 uses per sheet)

C.P. Bourg focuses on providing solutions integrated with sheetfed printing presses from leading manufacturers. Wrappers as well as booklet making systems integrated in-line with the printing machine have full two-way communication allowing for in-line parameter changes, error reporting, jamming and sheet re-printing if necessary. Production automation is supported by a JDF or barcode system.

It is the only solution on the market that allows the 100% to automate the production of booklets or books in a variety of formats while utilizing the full printing capabilities of the sheet and optimizing the cost of paper, printing and minimizing the human factor in production.

Akonda, as a distributor of the C.P. Bourg brand in Poland, is responsible for providing and servicing C.P. Bourg solutions to Polish customers.