UV printing on glass: Why is it a revolutionary technology for home decoration and advertising?

What is UV printing on glass and how does it work?

UV printing on glass is a modern digital printing technology that uses specialized polymer inks cured with UV light. In this method, the ink is precisely applied to the surface of the glass panels and then immediately cured using UV LED lamps. This process guarantees not only excellent image quality, but also exceptional durability and resistance of the print.

UV printing technology on glass uses the principle of polymerization, where liquid ink under ultraviolet light transforms into a solid state in a fraction of a second. This makes the print odorless, resistant to abrasion and discoloration, making it ideal for interior design and advertising projects.

Unique advantages of UV printing on glass

Excellent quality and resolution

UV printing on glass is characterized by photographic quality and the possibility of high resolution. Ink cured on the surface of the glass does not penetrate its structure, so colors remain vivid, saturated and sharp even in the most detailed graphic designs.

Unparalleled durability and resilience

UV-printed glass is distinguished by its exceptional resistance to:

- Abrasion and scratches

- UV radiation and color fading

- High and low temperatures

- Moisture and weather conditions

This high resistance means that UV-printed glass panels retain their aesthetics for years to come, which guarantees excellent value for money.

Ecological aspects of technology

Modern UV printing technologies, especially those using LED lamps, have low emissions. The process is odorless and does not require a long drying process, making it safe for both operators and end users.

Wide possibilities of using UV printing on glass

Decorative glass panels

UV printing on glass opens up a wide range of possibilities in space design:

- Wall panels with nature or abstract motifs

- Paintings and reproductions of artwork on glass

- Decorative partitions and partitions

- Glass furniture elements with author's graphics

Advertising and commercial applications

UV printing technology on glass will find application in:

- Company signs with logo and branding

- Storefronts with promotional graphics

- Interior signage in office buildings

- Tourist information on glass

Glass panels in the kitchen and bathroom

UV-printed glass panels are becoming particularly popular as:

- Splashback in the kitchen (panel between cabinets)

- Glass shower enclosures with discreet graphics

- Mirrors with decorative elements

- Wall panels in wet areas

Types of glass used in UV printing

Float glass

Standard float glass is the most commonly used material in UV printing on glass. It is characterized by a smooth surface and high transparency, which ensures excellent contrast and sharpness of the print.

Tempered glass

Tempered glass offers increased mechanical strength, making it an ideal choice for applications requiring high resistance to damage. UV-printed glass panels on tempered glass will find use in high-traffic areas.

Laminated glass

For projects that require special resistance or security, laminated glass is used, which even when damaged does not form dangerous shards.

The process of making UV printing on glass

Preparation of graphic design

The first step is to create appropriate graphics for printing. The design should include:

- Resolution of at least 150 dpi (on a 1:1 scale)

- CMYK color space

- Proper preparation of layers and elements

Printing on UV plotter

Today's UV printing plotters, such as Mimaki brand models and other professional UV printers, ensure precise ink application. The printing process includes:

- Application of polymer inks of successive colors

- Immediate curing of each layer with LED UV light

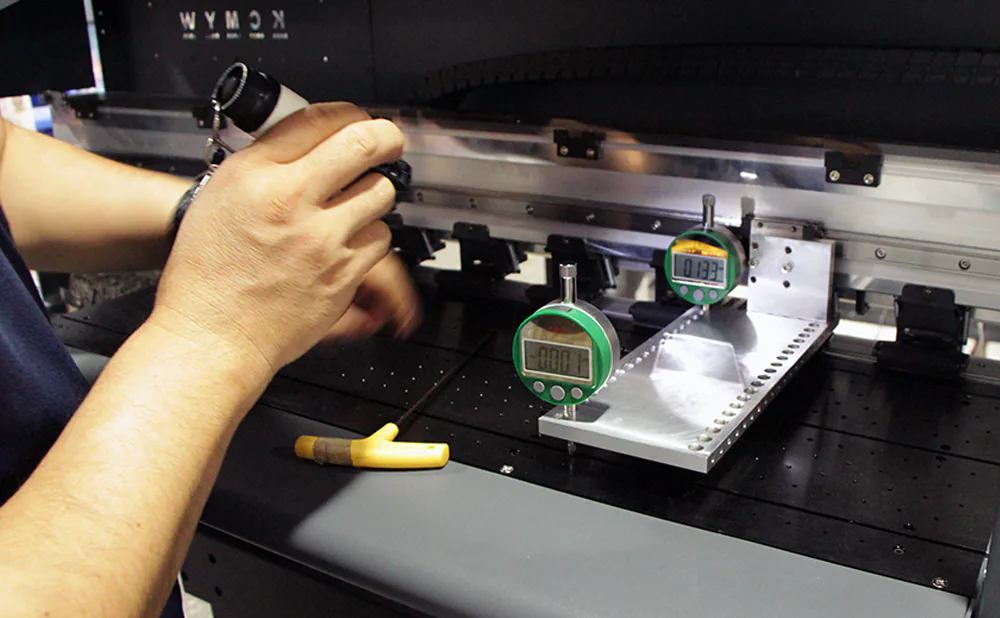

- Quality control and parameter adjustment

Finishing and installation of glass panels

Printing follows:

- UV print quality control

- Cutting glass to required dimensions

- Edge polishing

- Preparation for installation of glass panels

UV printing technologies: Flatbed vs. Roll-to-roll

UV flatbed printers

UV flatbed plotters are ideal for printing on glass because of:

- Possibility of placing a rigid glass on the table

- Positioning precision

- Ability to print on materials of different thicknesses

Advanced curing systems

Modern LED UV lamps offer:

- Low energy consumption

- Long life

- Uniform curing over the entire surface

- Ability to work in low temperatures

Costs and economics of UV printing on glass

Factors affecting the price

The price of UV printing on glass is affected by:

- Type and thickness of glass

- Imprint size

- Complexity of graphics

- Number of colors

- Circulation (number of pieces)

Comparison with other technologies

Compared to printed film or other methods of glass decoration, UV printing offers:

- Better durability (warranty often reaches 10 years)

- Greater resistance to external factors

- Higher image quality

- Simpler application

Choosing the right large format printing company

Criteria for evaluating printers

When choosing a printer for UV printing on glass, pay attention to:

- Type of UV printers used

- Experience in working with glass

- Portfolio of completed projects

- Available print formats

- Quality guarantee

Questions for printers

Before entrusting an assignment, it is worth asking about:

- Types of glass that the printer works with

- Possibility to make trial prints

- Lead time

- Print warranty terms and conditions

The future of UV technology on glass

The development of UV printing technology on glass is moving in the direction of:

- Increase printing speed while maintaining quality

- Expanded color gamut and special effects

- Integration with IoT systems for personalization

- Development of sustainable, eco-friendly inks

Summary

UV printing on glass is a technology that combines high quality with practicality and durability. Thanks to the use of modern UV plotters and technology UV LED curing, it is possible to create versatile solutions - from decorative glass panels to professional advertising solutions.

Whether you are planning an interior design using printed glass panels or want to create an effective advertising sign, UV printing on glass offers an unbeatable combination of aesthetics, functionality and durability. An investment in this technology is a guarantee of a long-lasting visual effect and satisfaction with the final result.