What is UV printing and what does the process involve?

UV printing represents a true revolution in digital printing technology, characterized by a unique image fixation process. In this innovative method, specialized polymer inks are precisely applied to the selected substrate, and then almost immediately cured by ultraviolet light. This is a form of direct printing, meaning that the digital image file is sent directly to the printer, which applies the ink to the surface of the material without the need for intermediate media.

The focal point of UV technology is the polymerization process initiated by special LED lamps that are integrated into the moving print head. UV radiation causes the liquid ink to go from a liquid to a solid state in a fraction of a second through a curing process. As a result, prints are immediately ready for further processing, which significantly speeds up the entire production process and increases the efficiency of printing techniques.

UV printing technology and its mechanism of operation

To fully understand the benefits of UV printing, it is helpful to know the details of the mechanism that makes this technology so unique. Key elements of the process include:

UV ink composition

The inks used in UV printing are advanced mixtures of liquid polymers containing:

- Monomers and oligomers - the basic components that combine under UV radiation

- Pigments - responsible for the color of the printout

- Photoinitiators - substances that absorb the energy of UV light and initiate the polymerization process

- Additives - to improve adhesion, fluidity and resistance

Importantly, modern UV printing ink contains low content or is completely free of VOCs, making this technique more environmentally friendly than traditional printing methods.

The role of UV lamps in the curing process

Two types of lamps are mainly used to initiate the polymerization process:

- Traditional mercury lamps - generating a broader spectrum of UV radiation

- Modern LED lamps - emitting UV light in narrower, specific bands

LED technology is gaining popularity due to its lower energy consumption, lack of ozone emissions, longer lifespan and ability to print on temperature-sensitive materials because it emits much less heat.

Three main UV printing systems

UV Flatbed printing

UV flatbed printers are designed primarily for printing rigid materials and flat sheets. Their design includes:

- A large, flat work table on which the material is placed

- Suction (vacuum) system to immobilize the substrate

- Movable carriage with print heads and UV lamps

This UV printing technique allows precise inkjet ink application on substrates such as PVC, Dibond, glass, MDF, Plexiglas (acrylic) or metal. Flatbed printers are available in a variety of formats, from smaller (90×60 cm) to large-format (2×3 m), enabling a wide variety of projects.

UV Hybrid Printing

Hybrid printers combine the capabilities of printing on rigid substrates with printing on flexible materials from a roll. They use:

- Advanced belt-based transport system

- Integrated unwind and rewind system for roll media

- Ability to quickly switch between different types of materials

This versatility makes hybrid printing an ideal solution for companies with a diverse portfolio of services, enabling complex projects requiring the use of different materials, such as overall advertising campaigns or interior design.

UV Roll-to-Roll Printing

UV roll-to-roll printing technology has been developed specifically for efficient printing of flexible materials delivered in roll form. The system includes:

- Precise mechanism unwinding material from the feeding roll

- System winding the printed material onto the receiving reel

- Advanced solutions to control material tension

These printers are ideal for banners, mesh nets, self-adhesive films and other materials used in large-format printing. Thanks to instant ink curing, prints are immediately dry and ready for further processing.

Advantages of UV printing

UV printing technology offers a number of fundamental advantages that have contributed to its rapid growth in the advertising and printing industry:

Versatility of substrates

One of the most distinctive features of UV printing is the ability to print on almost any type of material:

- Rigid panels: glass, metal, wood, ceramic, PVC, Plexiglas, Dibond

- Flexible materials: films, banners, textiles, leather, paper

- Three-dimensional objects: gadgets, fixtures, industrial components

This versatility gives printing and advertising companies the opportunity to Significantly expand its product offerings.

Exceptional durability and resistance of prints

Prints made with UV technology are characterized by exceptional resistance to:

- UV radiation - do not fade when exposed to sunlight

- Water and moisture - ideal for outdoor applications where they are exposed to weather conditions

- Abrasion and scratching - the hard surface of the cured ink provides mechanical protection

This high durability often eliminates the need for additional protection of prints by laminate, which is required for other printing techniques.

Excellent visual quality

UV technology makes it possible to obtain prints of very high quality:

- High resolution (up to 2880 dpi on some devices)

- Vibrant, saturated colors thanks to pigments that remain on the surface of the material

- Ability to use special effects: white ink as a base or selective color and varnish to create gloss, matte or 3D texture effects

Production speed and efficiency

Immediate UV curing of the ink eliminates the need for a long drying process, which:

- Shortens the production cycle

- Increases throughput

- Simplifies logistics (no need to store drying prints)

- Allows immediate further processing of the material

Ecological aspects

Compared to solvent printing, UV printing technology (especially using LED lamps) is more environmentally friendly:

- Low emissions of volatile organic compounds (VOCs)

- No unpleasant odors

- Lower energy consumption with LED lamps

- No mercury and ozone in LED systems

Application of UV printing in practice

The versatility of UV printing technology translates into a huge number of practical applications in various industries:

Flatbed printing

- Personalization of advertising gadgets (phone cases, powerbanks, flash drives)

- Interior and exterior signage (signs, information boards, nameplates)

- Decorative panels on various substrates (glass, PVC, Dibond) for interior decoration

- Printed furniture fronts and interior design elements

- Packaging and advertising stand prototypes

- Printing on ceramic tiles, industrial components

- 3D letters and spatial elements with convex effect

Hybrid Printing

- Complex trade fair and exhibition stands

- Advertising campaigns and POS (Point of Sale) materials.

- Interior decoration combining different media (from wallpaper to glass elements)

- Mixed production of small batches on a variety of materials

Roll-to-Roll Printing

- Large format banners and outdoor advertising graphics

- Custom murals for interior decoration

- Vehicle wrapping (car wrapping) on self-adhesive film

- Textile flags and banners (soft signage)

- Illuminated graphics for lightboxes and light boxes

- Stickers, labels and window films

Materials compatible with UV printing

UV printing technology allows us to print an extremely wide range of materials:

Rigid substrates:

- Plastics: foamed and hard PVC, Plexiglas (PMMA), polycarbonate, polystyrene

- Composite materials: Dibond (polyethylene core with aluminum layers), Palboard

- Glass: float, tempered, laminated, mirrors

- Wood and wood-based materials: solid wood, plywood, MDF, HDF boards

- Metals: aluminum, steel, brass, copper

- Ceramics and stone: ceramic tiles, marble, granite

- Cardboard and paperboard: corrugated cardboard, solid cardboard, specialty cartons

Flexible substrates:

- Vinyl banners: frontlit, backlit, blockout

- Mesh nets: perforated materials that let the wind through

- Self-adhesive films: monomeric, polymeric, spouted

- Foils for backlighting (backlit)

- Papers: poster, photographic, synthetic

- Textiles and fabrics: polyester materials, canvas (canvas)

- Wallpaper: paper backings, fleece backings, vinyl backings

- Leather and eco-leather

UV printing vs. other printing techniques

UV printing vs. Solvent printing

When comparing UV printing technology with solvent printing, it is worth noting the key differences:

- Drying/curing process:

- UV printing: Instant ink curing with ultraviolet light

- Solvent printing: Slow evaporation of solvents, requiring time

- Ecological aspects:

- UV printing: Low VOC emissions, no odors

- Solvent printing: High VOC emissions, intense odor

- Durability:

- UV printing: High mechanical resistance without additional protection

- Solvent printing: often requires lamination for durability

- Material Compatibility:

- UV printing: Virtually unlimited (rigid and flexible materials)

- Solvent printing: mainly flexible, absorbent materials

UV printing vs. Latex printing

Differences between UV technology and latex printing:

- Fixation process:

- UV printing: Ultraviolet light curing, low temperatures

- Latex printing: Thermal fixation, high temperatures

- Energy consumption:

- UV (LED) printing: Low energy consumption

- Latex printing: Higher energy consumption (heating)

- Compatibility with temperature-sensitive substrates:

- UV printing: Wide compatibility

- Latex printing: Limitations with heat-sensitive materials

Disadvantages of UV printing and biggest limitations

Despite its many advantages, UV printing technology also has some limitations:

- Investment costs:

- UV printers require significant initial investment, especially advanced flatbed and hybrid systems.

- Ink Flexibility:

- Standard UV ink can crack on flexible surfaces when bent, although special formulas with increased flexibility now exist.

- Technical knowledge required:

- Operating advanced UV printers requires specialized knowledge and training.

- Limitations in color saturation on absorbent substrates:

- Because the ink cures on the surface rather than penetrating the structure of the material, colors may be less saturated on some absorbent substrates than with solvent or latex printing.

- Limited thermoforming capability:

- Standard UV inks are not suitable for deep thermoforming, although special formulations partially solve this problem.

The future of UV printing

UV printing technology is constantly evolving. Printer manufacturers are striving to further improve their solutions by:

- Increase printing speed while maintaining high quality

- Improving the quality of UV printing and expanding the color gamut

- Development of inks with better adhesion to difficult surfaces and increased flexibility

- Improving UV LED technology for energy efficiency

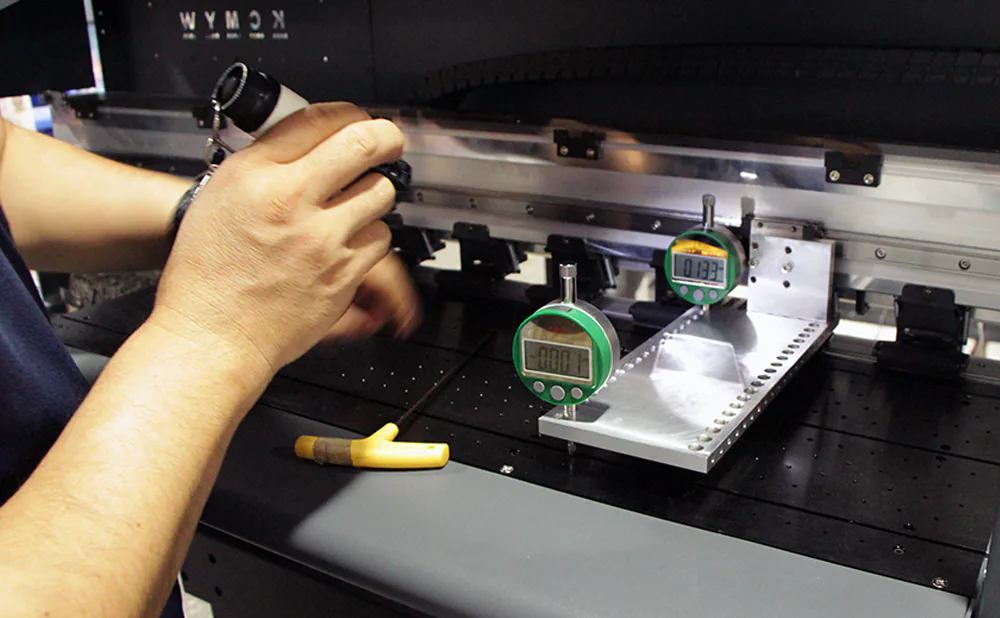

- Process automation loading/unloading and quality control

- Increasing aspects of sustainability and environmental performance

Why is UV printing the technology of the future?

Investing in UV technology allows companies to:

- Diversify offerings and enter new dynamic market segments

- Gain a competitive edge with higher quality and longer lasting prints

- Optimize production processes and reduce lead times

- A response to the growing demands of customers expecting durable, aesthetic and personalized products

Whether choosing UV flatbed printing for precision printing on flat materials, a hybrid system for versatile applications, or a roll-to-roll solution for large-format graphics, the technology offers unparalleled opportunities for the advertising, decorative and industrial industries, combining high quality with print durability and production efficiency.

UV printing is not just another printing technology, but a strategic tool that opens up exciting new opportunities for companies to grow in the rapidly changing world of printing.

FAQ - UV Printing - Frequently Asked Questions

Basic questions about UV printing

What is UV printing?

UV printing is a state-of-the-art digital printing technology that uses specialized polymer inks that are instantly cured by ultraviolet light. This process guarantees high quality, durability and speed of production.

What is the difference between UV printing and traditional printing methods?

The main differences are:

- Instant curing: No drying time, immediately ready for further processing

- Versatility of substrates: Ability to print on almost any material

- Durability: Exceptional weather and abrasion resistance

- Quality: Sharp contrasts and vivid colors

Which materials can be UV printed?

UV printing allows you to print a wide range of materials:

- Stiff: glass, metal, wood, PVC, Dibond, plywood, ceramic

- Flexible: films, banners, fabric, leather, paper

- Unusual: 3D objects, gadgets, electronics components

Technology and process

How does the UV ink curing process work?

UV inks contain photoinitiators that, when exposed to UV light (emitted by LED lamps), trigger the polymerization process. In a fraction of a second, the liquid ink transforms into a hard, resistant film.

Is UV printing safe for health?

Yes, modern UV printing is safe:

- LED UV inks contain minimal amounts of VOCs

- The process is odorless

- Does not emit harmful fumes

- LED lamps do not emit ozone

What is the durability of UV prints?

UV prints are characterized by exceptional durability:

- UV resistance: They do not fade in the sun

- Waterproof: Moisture and rain resistant

- Mechanical resistance: They do not scuff or scratch.

- Lifespan: 5-10 years in outdoor applications, virtually unlimited indoors

Types of UV printers

What is the difference between flatbed, hybrid and roll-to-roll printers?

- Flatbed: Designed for rigid materials, flat work table

- Hybrid: Combine printing capabilities on rigid and roll materials

- Roll-to-roll: Specialize in printing on flexible materials from rolls

How to choose the right type of UV printer?

The choice depends on:

- The type of materials you plan to print on

- Formats and thickness of substrates

- Production inputs

- Available production space

- Investment budget

Costs and practicalities

How much does UV printing cost?

Costs depend on:

- Type and quality of material

- Print size

- Graphic complications

- Circulation (number of pieces)

- Region and printers

Typically, UV printing is more expensive than traditional methods, but offers much better quality and durability.

Does UV printing require special file preparation?

Yes, it is recommended:

- Resolution of at least 150-300 DPI

- CMYK color space

- Consideration of substrate type in the design

- Consultation with the printer before preparing the file

How long does it take to complete a UV printing order?

Lead time is usually:

- Smaller orders: 1-3 business days

- Larger projects: 3-7 working days

- Complex implementations: Up to 14 days

The exact time depends on the printer, the print run and the type of material.

Quality and limitations

What are the limitations of UV printing?

The main limitations are:

- Higher costs than traditional methods

- Limited flexibility of standard inks (problem solved by special formulations)

- Risk of cracks in extreme bending of materials

- Required technical knowledge to operate

Can white ink be printed with UV technology?

Yes, this is one of the main advantages of UV printing. White ink can be used as:

- A primer for colors on dark/transparent materials

- Selective color in design

- Element of special projects

Is UV printing suitable for food applications?

Standard UV inks are not certified for food contact. There are special certified inks for food packaging, but they require a specialized printer and certification.

Maintenance and upkeep

How to take care of UV prints?

UV prints are very easy to maintain:

- Cleaning: Gentle cleaners, avoid abrasive products.

- Storage: In a dry place, avoid direct sunlight (applies to some materials)

- Support: Caution in heavy use

Can UV prints be repaired after damage?

Minor damage can sometimes be repaired by:

- Local repainting

- Application of protective film

- In the case of major damage, re-printing is usually necessary

The future of UV printing

What are the prospects for the development of UV technology?

The main directions of development are:

- Increase in speed while maintaining quality

- Development of inks with greater flexibility and new properties

- Process automation and integration with Industry 4.0

- Ecology: Developing even greener solutions

Will UV printing replace traditional printing methods?

UV printing will not completely replace traditional methods, but it will continue to gain popularity due to its unique advantages. In many applications it is already the preferred method, especially where quality, durability and versatility are important.