Wrappers

Start producing softcover bindings today.

You can also make blocks / notebooks on the wrapping machines.

Contact our company for detailed information on Fastbind.

-

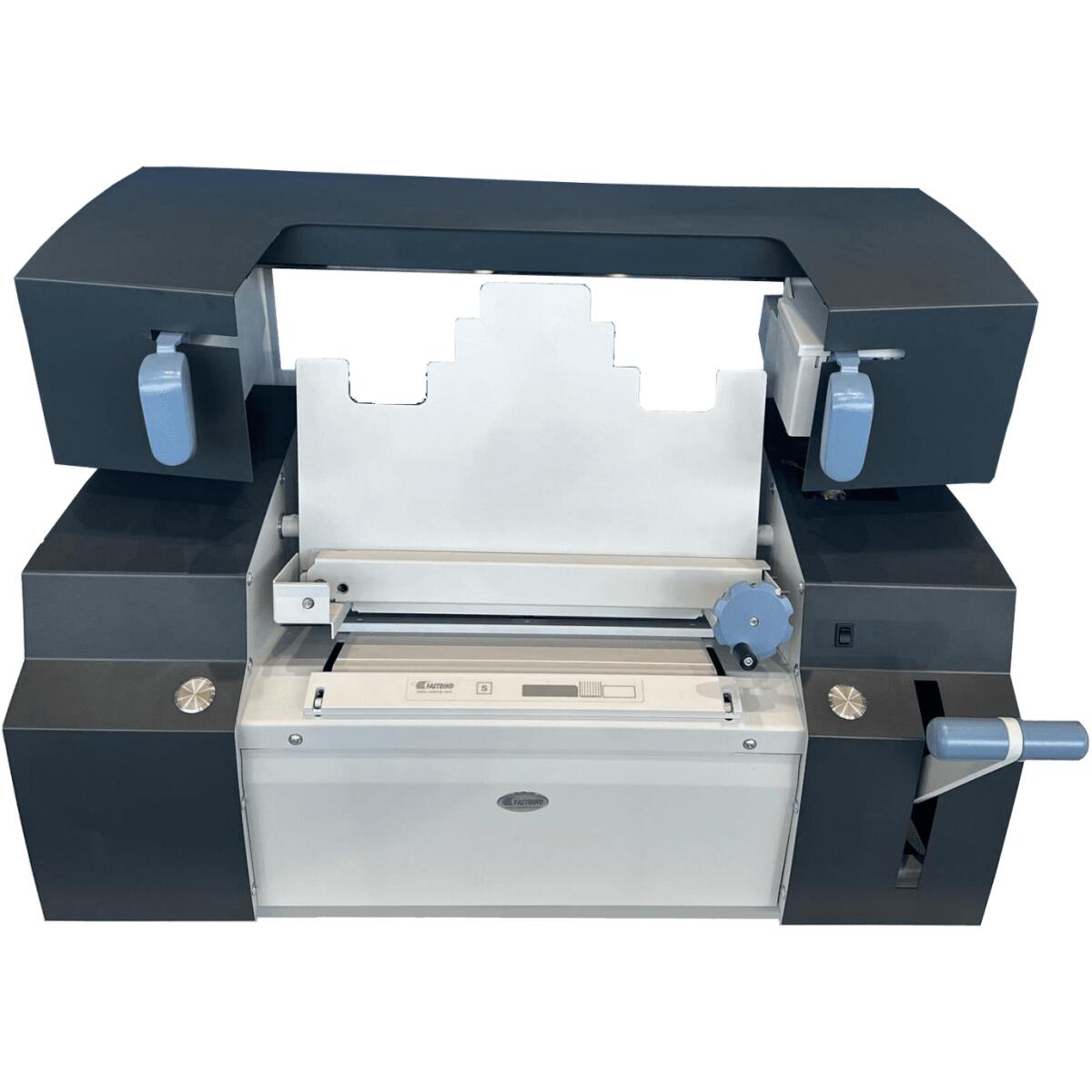

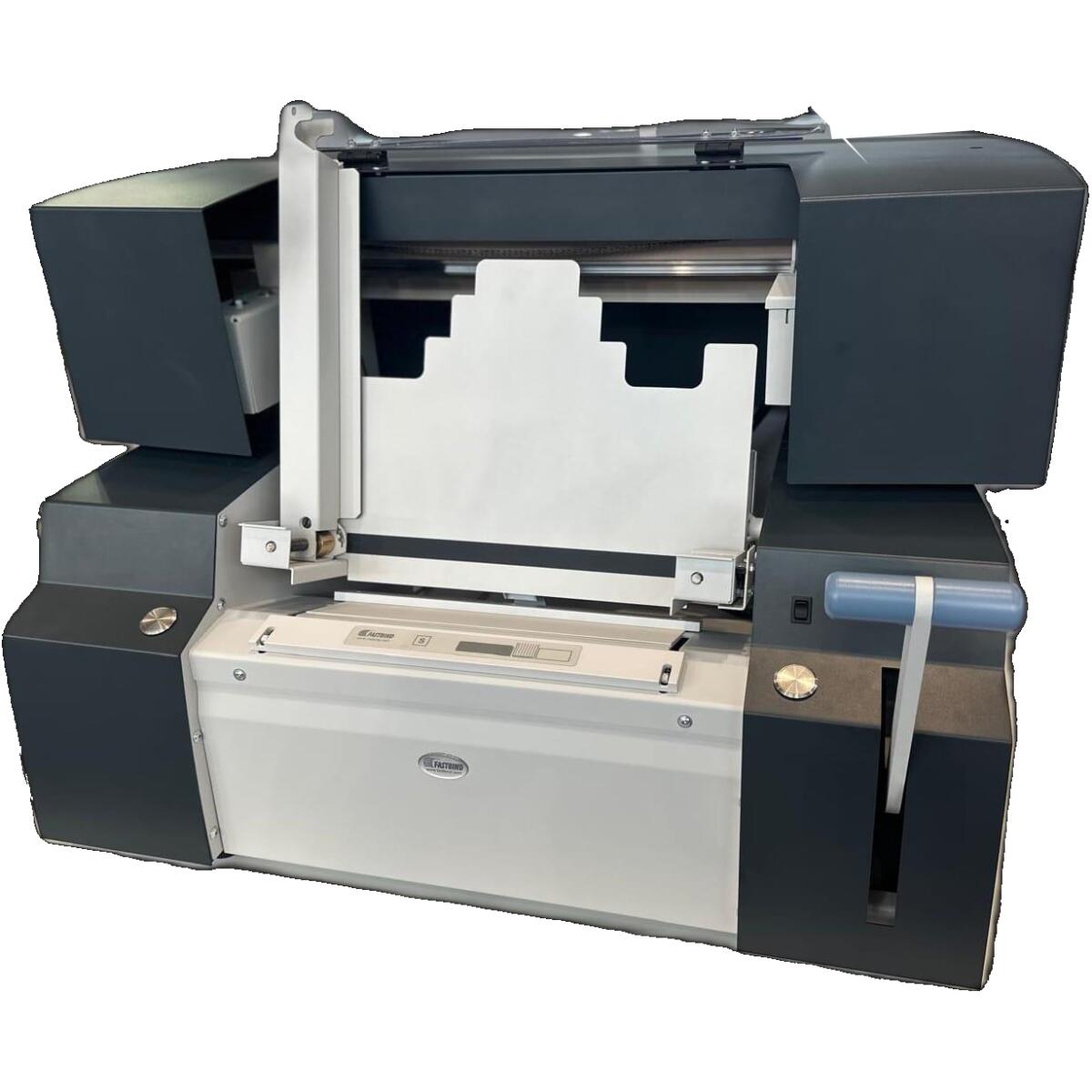

Fastbind One Handy Perfecting Machine

-

Fastbind One Sense Optima Perfect Wrapping Machine

-

Fastbind One Sense Ultra wrapping machine

-

Fastbind PUREVA SMART CUBE edge binder

-

Fastbind PUREVA Smart Perfect Wrapping Machine

-

Fastbind EVA XT edge binder

-

Fastbind PUREVA NEO™ Perfect Edgebander

-

Fastbind PUREVA XT edge binder

-

Fastbind Elite XT edge binder

-

Fastbind Elite Perfecting Machine

-

Fastbind Secura edge binder

Book wrappers - a comprehensive guide to softcover binding

What is soft binding and why does it dominate digital printing?

Soft binding, also known as glue binding or paperback, is a bookbinding technique that involves bonding the book insert to the cover with glue. Unlike hardcover binding, softcover binding is characterized by a flexible cover and much lower production costs, making it the dominant solution in digital printing, especially in the print-on-demand model.

Modern book binders have undergone a technological revolution, transforming from simple manual devices to advanced production systems capable of full automation - from digital printing to the finished book. The integration of bookbinding machines with digital printers eliminates manual labor and allows each book to be produced as a unique piece without sacrificing productivity.

Bonding technologies in modern oklејar

EVA (Ethylene-Vinyl Acetate) glue

EVA adhesive is a traditional thermoplastic technology that cures after cooling. It is characterized by fast drying time and high production efficiency. Modern EVA systems offer separate side gluing, which increases the strength of the binding and prevents sheets from falling out. An operating temperature of 130-180°C ensures optimal penetration of the adhesive into the paper structure.

PUR (Polyurethane Reactive) glue

PUR glue represents state-of-the-art book bonding technology. Unlike EVA, PUR glue reacts chemically with moisture from the air to form an extremely durable bond. Books bound with PUR glue can be opened flat without risking damage to the spine, and the binding remains flexible for many years. The hermetically sealed PUR system does not require daily cleaning, reducing operating costs.

Levels of automation of edgebanding machines

Desktop handwrapping machines

Basic solutions ideal for small print shops, design offices or schools. The operator manually places the cartridge in the machine, applies the cover and activates the gluing cycle. They are characterized by low investment costs and fast turnaround time, but limited productivity (several dozen books per day).

Semi-automatic machines with manual adding

The operator adds the insert and rebound cover, and the machine automatically performs spine milling, gluing and cover pressing. Semi-automatic solutions offer a compromise between productivity (up to 200-300 books per hour) and investment costs, proving suitable for print shops with medium print runs.

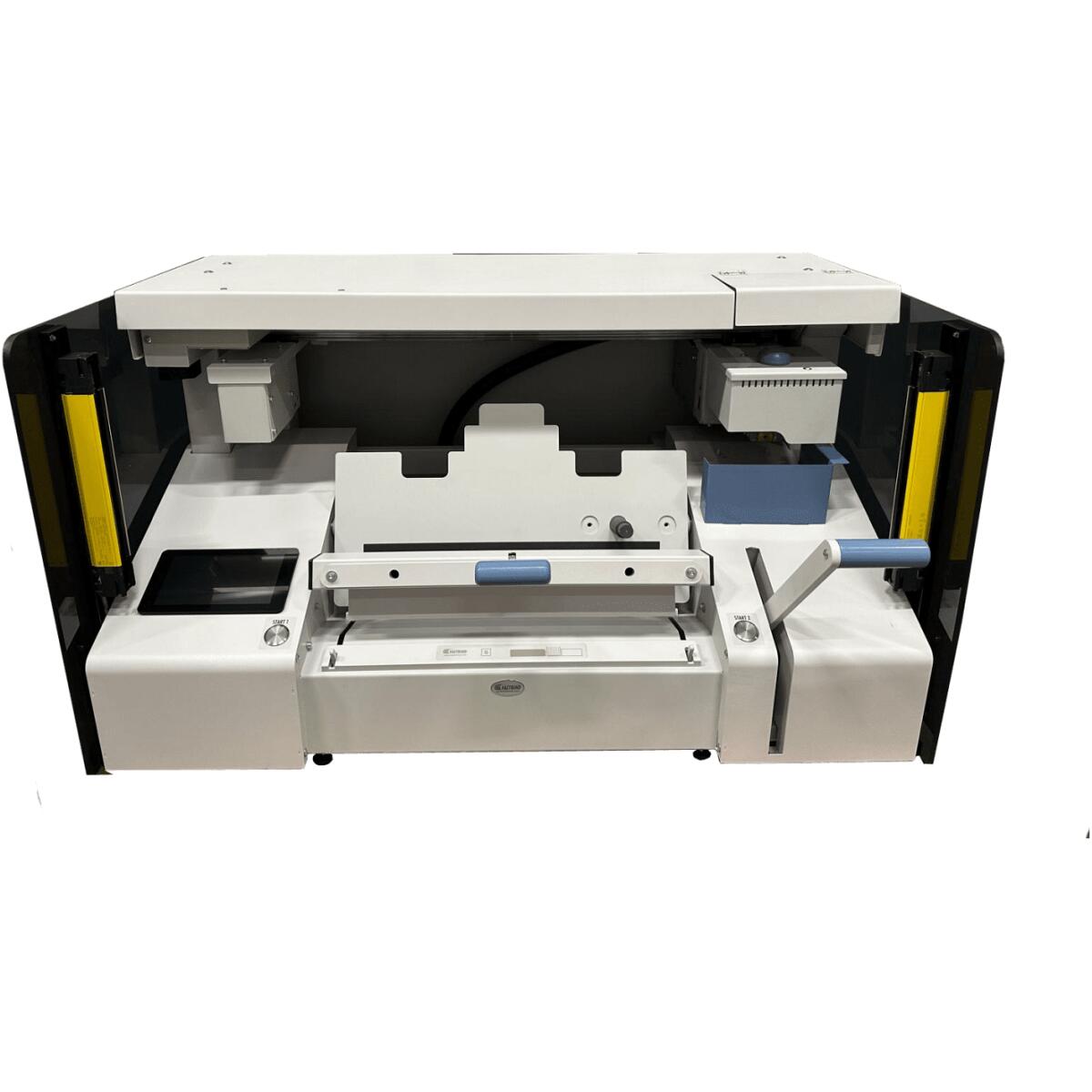

Offline vending machines with feeders

Advanced binders equipped with automatic feeders for inserts and covers. BBL's unique solution allows loading up to 120 inserts - the machine will take and bind each insert by itself without operator intervention. Capacity of up to 350 books per hour with the flexibility to produce variable print runs.

Full inline automation with printer

The highest level of automation - a complete production line "from file to finished book". The wrapping machine is directly connected to the digital printer and tripod, creating an integrated production system. Certified cooperation with leading manufacturers (Canon, Xerox, HP Indigo, Konica Minolta, Ricoh, Kodak) ensures smooth communication and trouble-free operation.

Key technologies in professional oklејarkers

Smart clamp with calibre

A self-adjusting clamp with a built-in caliber automatically measures the thickness of the book insert (from 1 to 60 mm) and sets all parameters in a fraction of a second: milling depth, position of the big on the cover, pressure force and gluing time. This eliminates the need for manual adjustments and reduces production preparation time.

Professional back milling

A powerful milling module with 0-3 mm adjustment and four notching knives aggressively opens the paper structure, guaranteeing perfect glue penetration. Proper spine preparation is key to binding durability - milling too shallow leads to a weak bond, while milling too deep can damage the inner text.

Knife creasing of covers

Unlike standard creasing with a wheel, professional creasing machines use knife creasing. This method does not break or damage paper fibers, guaranteeing a perfect fold line without toner cracking, even on dark, fully printed or laminated covers. The ability to make up to 13 creases allows the production of books with wings.

Applications of edgebanding machines in different production models

Print-on-Demand

The book-on-demand model is a revolution in publishing - each book can be printed and bound individually upon receipt of an order. Advanced binders, such as the BB3002, make it possible to produce even single copies without losing productivity. Each subsequent book can be different from the previous one - a different title, format or thickness.

Short series for publishers

Small print runs of 50-500 copies become economically viable by automating the process and eliminating preparation costs. Publishers can test the market with new titles without the risk of overproduction, and quickly add more copies if successful.

Corporate and training materials

Softbound training manuals, product catalogs, reports and technical documentation combine professional appearance with functionality. The ability to quickly update content and produce personalized versions for different audiences increases the value of training materials.

Performance parameters and technical capabilities

Range of formats and weights

Modern wrappers support a wide range of formats - from small 90 x 60 mm booklets to large 385 x 320 mm albums. The ability to work with thicknesses from 1 to 60 mm and insert weights of 60-160 gsm and cover weights of 80-300 gsm ensures versatility of applications.

Production speed and efficiency

The capacity of professional edge banding machines reaches 600 cycles per hour in offline mode, which translates into the production of up to 350 books per hour at standard thicknesses. In inline mode with a digital printer, the production speed is limited by the capacity of the printing machine, but the entire process runs without operator intervention.

Energy consumption and operating costs

Modern edge banding machines feature optimized power consumption - 4000W in running mode, 1500W in standby mode. Waste-free PUR system and long-life milling knives minimize the cost of consumables, increasing production profitability.

Expansion to a complete production line

Integration with tripod

The addition of the CMT-330TC automated tripod creates a complete "book factory" - from the printed sheet to the finished book trimmed on three sides. The system works without manual intervention or changing clamps, even when producing single copies that differ in format.

Interface and communication modules

Bourg Book Compiler (BBC) and other interface modules ensure seamless communication between the printer and the wrapper. The system automatically retrieves job parameters (format, thickness, cover type) from the prepress file, eliminating the risk of errors and speeding up production preparation.

Softcover wrappers are the cornerstone of modern book production in digital printing. Choosing the right level of automation - from manual desktop machines to full inline lines - determines a printer's production capabilities and competitiveness in the booming on-demand printing market.