Basic Information - Rotary Rigging

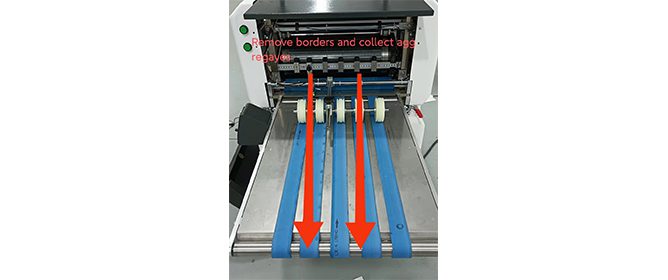

The MCT rotary die cutting machine has an openwork separation module, which falls into a box under the belt on the lining and thus we have ready blanks. It is ideal for medium-volume production of stickers, boxes, labels, cards with irregular shapes. The machine had its European premiere at FachPack in Nuremberg and is ready for presentation is Akonda's show-room.

Compact size - many applications

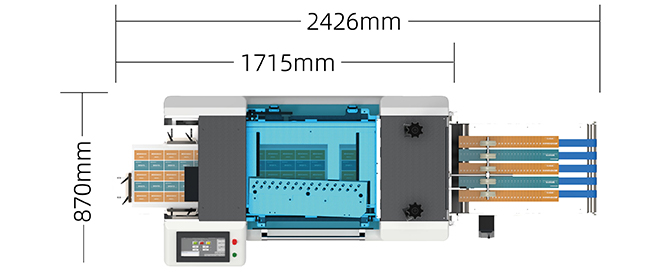

With its small footprint and easy operation, the MCT series intelligent rotary die cutter is designed for small and medium-sized productions. The machine is widely used for self-adhesive stickers, postcards, wine labels, clothing hang tags, playing cards and other print and packaging products, having its applications in the apparel and electronics industries. With the iECHO, rotary die cutting has never been so fun and compact.

Main product features - Rotary MCT

Small size saves space

Convenient touchscreen

Safer replacement of punches

Accurate and fast downloading

Explore the capabilities of the machine

Automatic feeding system

Correction system

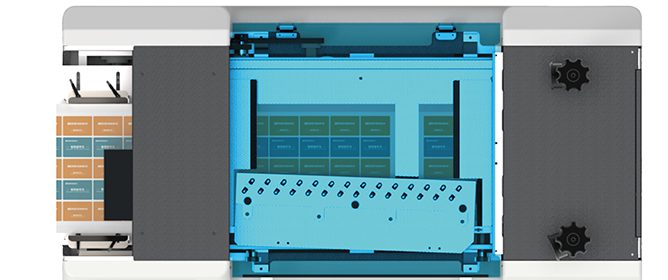

Cutting layout

Waste disposal system

Material feeding system

See the device in action

With an intelligent sheet feeder, automatic and precise alignment, the sheets pass through roller assemblies onto which a magnetic die cutter is applied, performing a variety of die cutting processes such as full cutting, notching, perforating and creasing. Printing bookbinding equipment for process automation - see for yourself!

See other printing equipment iECHO